Preparation method of high-temperature-resistant flame-retardant polyimide modified melamine oil-absorbing foam

A polyimide, flame-retardant technology, which is applied in the field of polymer foam plastics, can solve the problems of narrow application field, high cost of foam itself, limited use of oil-absorbing materials, etc., and achieves high temperature resistance, high hydrophobicity and lipophilicity. , the effect of high flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

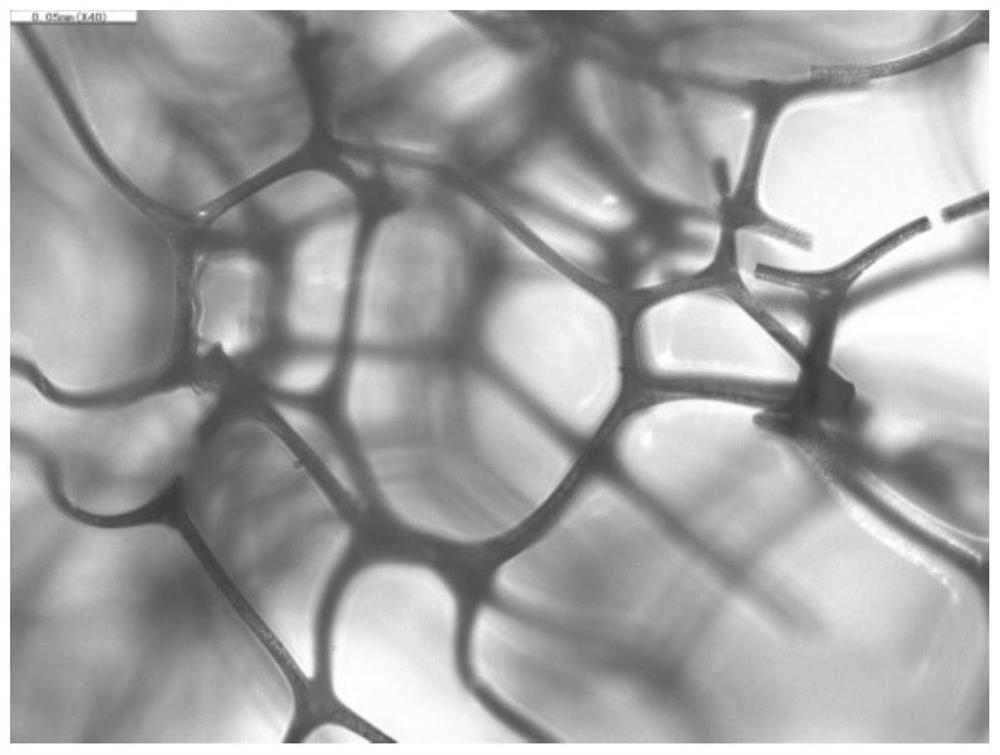

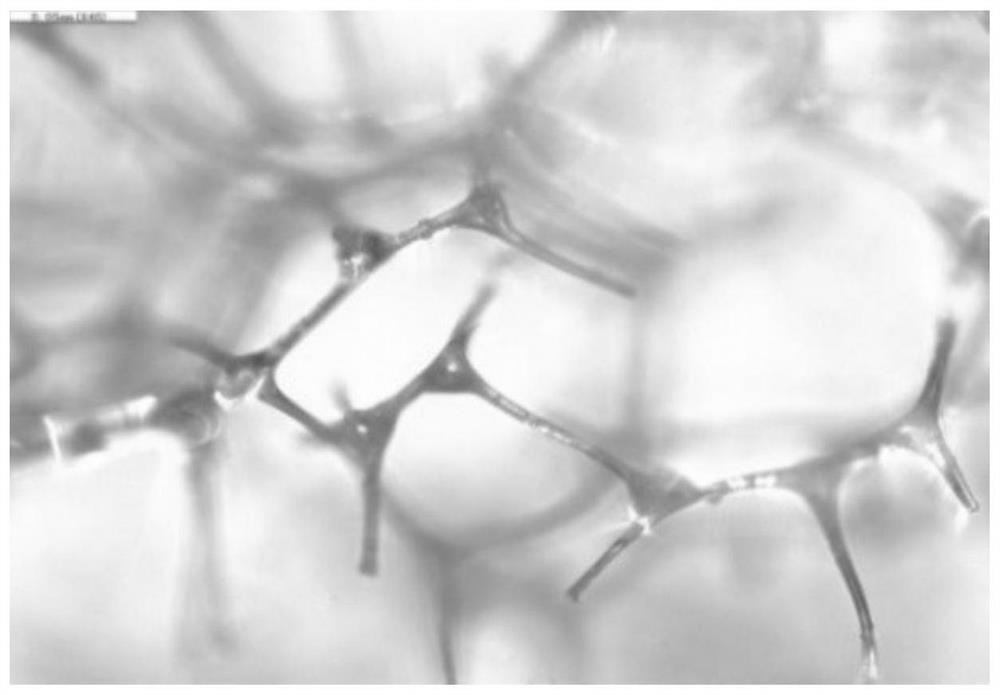

[0051] The preparation method of the high temperature resistant flame retardant polyimide modified melamine oil-absorbing foam of the present invention, the detailed steps of the preparation method are as follows:

[0052] a. Using melamine and paraformaldehyde as raw materials, according to the molar ratio of melamine and paraformaldehyde 1:2.8, add 90.00 g of melamine and 60.00 g of paraformaldehyde into a three-necked flask equipped with mechanical stirring, condenser and thermometer for mixing, After mixing, add 51.50 g of deionized water as a solvent until the solid content of the mixed system is 74.44%, and add an aqueous sodium hydroxide solution with a concentration of 20% by mass to adjust the pH value of the mixed system to 9.5; then use an oil bath to heat up and react , control the reaction temperature to be 80-85°C, after the reaction system is clarified, continue to insulate and react at 80-85°C until the cloud point, and the reaction is completed; after the react...

Embodiment 2

[0059] The preparation method of the high temperature resistant flame retardant polyimide modified melamine oil-absorbing foam of the present invention, the detailed steps of the preparation method are as follows:

[0060] a. Using melamine and paraformaldehyde as raw materials, according to the molar ratio of melamine and paraformaldehyde of 1:2.5, 90.00 g of melamine and 53.57 g of paraformaldehyde were added into a three-necked flask equipped with mechanical stirring, condenser and thermometer for mixing, After mixing, add 61.50 g of deionized water as a solvent until the solid content of the mixed system is 70.0%, and add an aqueous sodium hydroxide solution with a concentration of 15% by mass to adjust the pH value of the mixed system to 9.3; then use an oil bath to heat up and react , control the reaction temperature to be 80-85°C, after the reaction system is clarified, continue to insulate and react at 80-85°C until the cloud point, and the reaction is completed; after ...

Embodiment 3

[0067] The preparation method of the high temperature resistant flame retardant polyimide modified melamine oil-absorbing foam of the present invention, the detailed steps of the preparation method are as follows:

[0068] a. Using melamine and paraformaldehyde as raw materials, according to the molar ratio of melamine and paraformaldehyde of 1:2.3, melamine 90.00g and paraformaldehyde 49.24g were added into a three-necked flask equipped with mechanical stirring, condenser and thermometer for mixing, After mixing, add 74.98 g of deionized water as a solvent until the solid content of the mixed system is 65.00%, and add an aqueous solution of sodium hydroxide with a concentration of 10% by mass to adjust the pH of the mixed system to 9.0; then use an oil bath to heat up and react , control the reaction temperature to be 80-85°C, after the reaction system is clarified, continue to insulate and react at 80-85°C until the cloud point, and the reaction is completed; after the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com