Resourceful treatment method for fluorine-containing waste generated by aluminum electrolysis and aluminum fluoride product

A treatment method and a resource-recycling technology, applied in the field of metallurgical solid waste treatment, can solve the problems of inability to directly apply aluminum electrolytic production, and the amount of precipitation is small, and achieve the effect of promoting sustainable development, improving purity and particle size, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

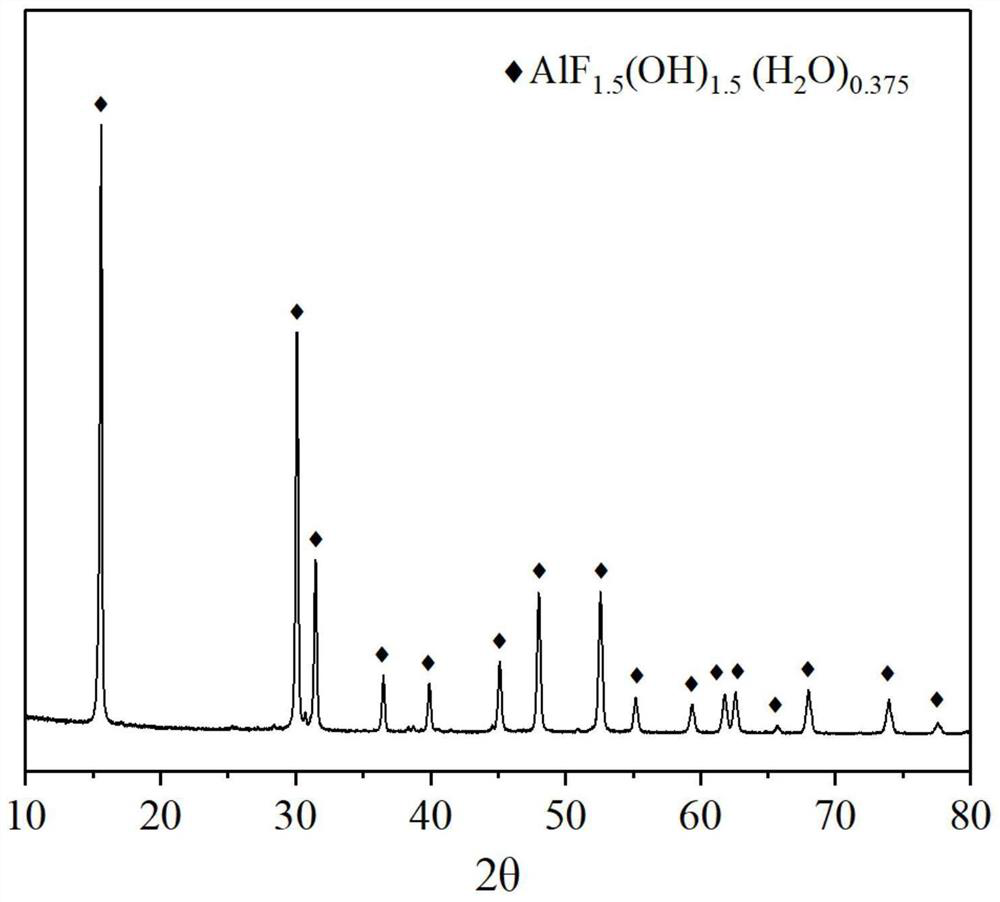

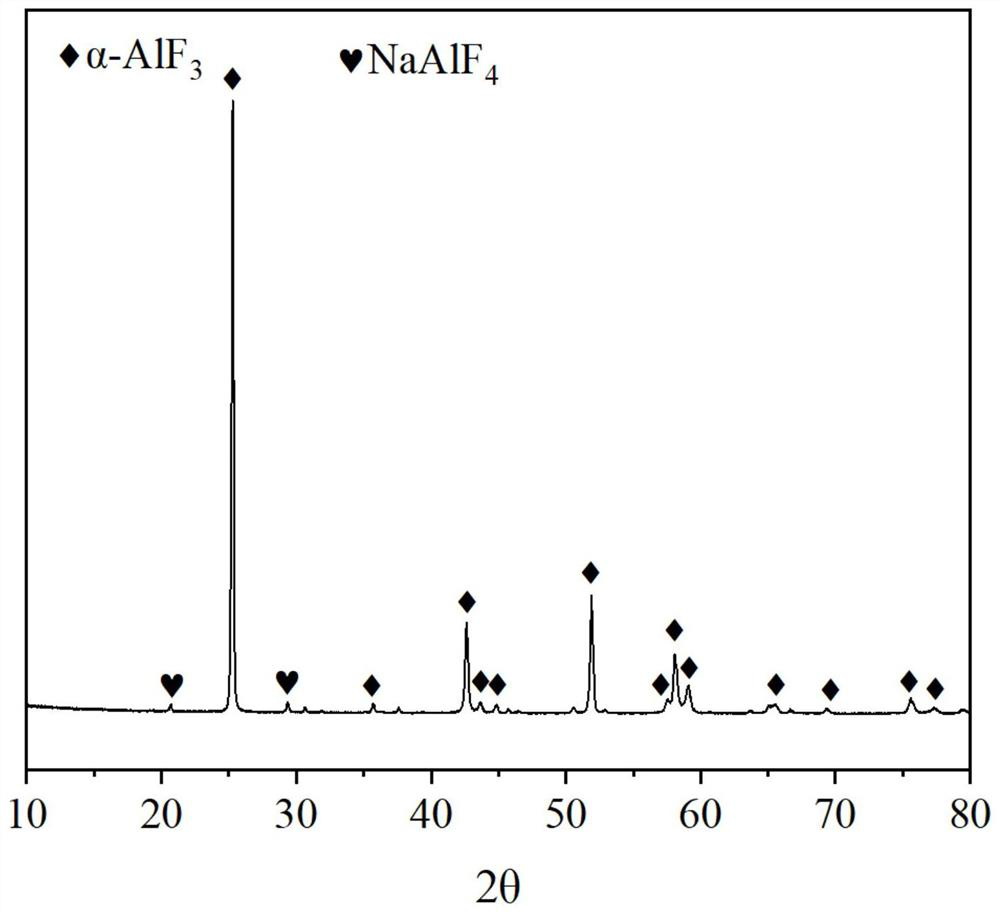

[0051] The specific implementation steps of this embodiment are as follows:

[0052] (1) Take 100g of waste electrolyte from an electrolytic aluminum factory in Henan (XRF detects that the contents of each component are potassium fluoride 3.59wt.%, lithium fluoride 5.25wt.%, calcium fluoride 4.03wt.%, magnesium fluoride 0.45wt %, alumina content 2.65wt.%, and the rest is cryolite with a molecular ratio of 2.30), crushed and sieved to below 100 mesh to obtain 100g spent electrolyte powder for subsequent use;

[0053] (2) Pour 79.2g of spent electrolyte powder into 1L of 100g / L aluminum chloride solution, stir and react at 80°C for 4h, and filter to obtain filtrate A and 11.5g of leaching residue.

[0054] (3) Use 1mm thick ruthenium-iridium-coated titanium plates to make cathode and anode, and plexiglass plate to construct the electrolytic cell body, use cation exchange membrane to cut off between cathode and anode (form anode chamber and cathode chamber), and carry out electro...

Embodiment 2

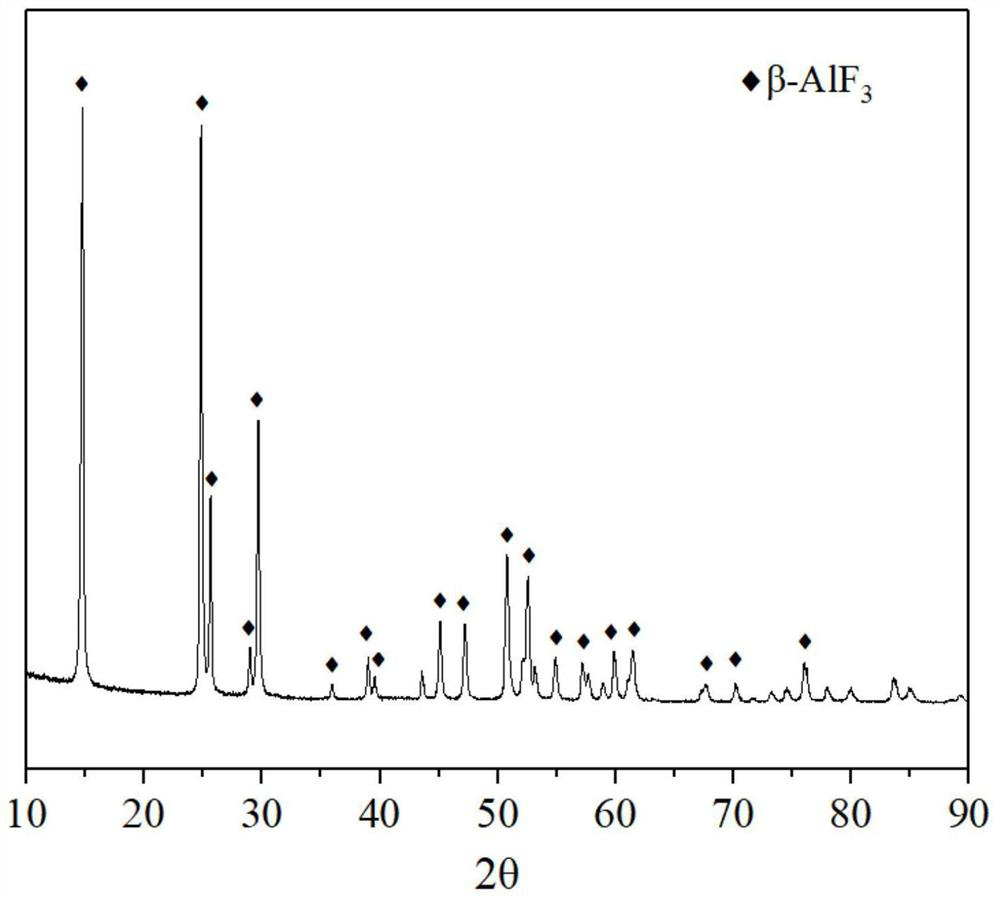

[0060] Repeat Example 1, the difference is only: in step (3), when the pH value is 1.5, stop the electrolysis. The results of the obtained aluminum fluoride product are shown in Table 1.

Embodiment 3

[0062] Repeat Example 1, the only difference is: in step (3), when the pH value is 5.5, stop the electrolysis. The obtained aluminum fluoride product results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com