A kind of water-based polymer suspoemulsion and preparation method thereof

A technology of high molecular polymer and suspoemulsion, applied in the field of polymer functional additives, to achieve the effect of no dust pollution, high effective content and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

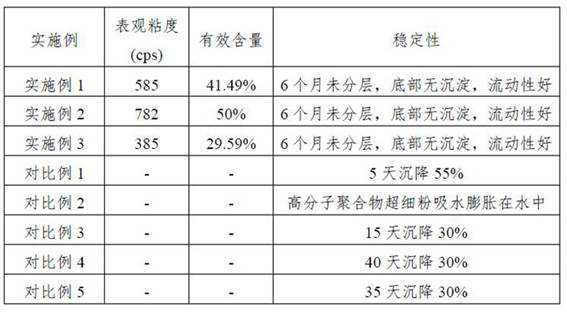

Examples

preparation example Construction

[0024] The present invention provides a kind of preparation method of water-based polymer suspoemulsion in the first aspect, described method comprises the steps:

[0025] (1) Mix low molecular polymer solution, wetting agent, thixotropic agent and viscosity modifier with water to make a mixed solution.

[0026] (2) Add high molecular polymer fine powder to the mixed liquid, then homogenize after stirring evenly, and then filter to obtain water-based high molecular polymer suspoemulsion; the present invention finds that adding the mixed liquid The high molecular polymer fine powder is easy to clump into small balls because the particles are relatively fine. The present invention finds that the high molecular polymer fine powder small balls can be effectively dispersed by shear force after being homogenized. There are no special requirements for the specific operation process and operating equipment of homogenization. For example, it can be homogenized by emulsification pump an...

Embodiment 1

[0047] ①Preparation of low-molecular polymer solution, the preparation method is as follows: 300g of sodium allyl sulfonate, 15g of 2-acrylamido-2-methylpropanesulfonic acid (ATBS), 400g of deionized water, 30g of ammonium sulfate, add Ammonium persulfate 0.1g, dissolve completely, add 0.05g of sodium bisulfite, heat up to 57°C and keep the temperature, mechanically stir for 4 hours, drop to normal temperature and discharge for later use, the low molecular polymer in the prepared low molecular polymer solution The viscosity average molecular weight is 160,000.

[0048] ② Prepare a wetting agent, which is prepared by mixing AEO-9 and isomeric tridecyl polyoxyethylene ether according to a mass ratio of 1:1.

[0049] ③Preparing a thixotropic agent, the thixotropic agent is formed by uniformly mixing isomeric tridecyl alcohol, cetyl alcohol, and stearyl alcohol in a mass ratio of 1:1:1.

[0050]④ Grinding high-molecular polymers (linear ultra-high molecular weight polyacrylamide ...

Embodiment 2

[0054] ①Preparation of low-molecular polymer solution, the preparation method is as follows: 400g sodium allyl sulfonate, 17g 2-acrylamido-2-methylpropanesulfonic acid (ATBS), 350g deionized water, 40g ammonium sulfate, add over Ammonium sulfate 0.2g, dissolve completely, add sodium bisulfite 0.15g, heat up to 55 ℃ and keep the temperature, mechanically stir for 5 hours, drop to normal temperature and discharge for later use, the low-molecular polymer in the prepared low-molecular polymer solution The viscosity average molecular weight is 130,000.

[0055] ② Prepare a wetting agent, which is prepared by mixing AEO-7 and isomeric tridecanol polyoxyethylene ether according to a mass ratio of 3:1.

[0056] ③ Prepare a thixotropic agent, which is formed by mixing isomeric tridecyl alcohol and stearyl alcohol according to a mass ratio of 3:1.

[0057] ④ Grinding high-molecular polymers (linear ultra-high molecular weight polyacrylamide with a viscosity-average molecular weight of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com