Blocky biological water-soluble fertilizer and preparation method thereof

A water-soluble fertilizer and biological technology, applied in potash fertilizers, nitrogen fertilizers, phosphate fertilizers, etc., can solve the problem of limited salt tolerance of functional microorganisms, and achieve the effects of increased artificial management and maintenance costs, strong salt tolerance, and easy transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

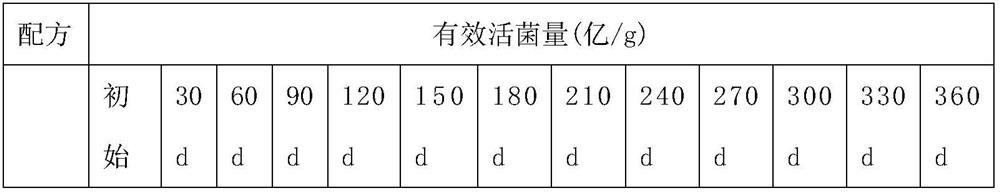

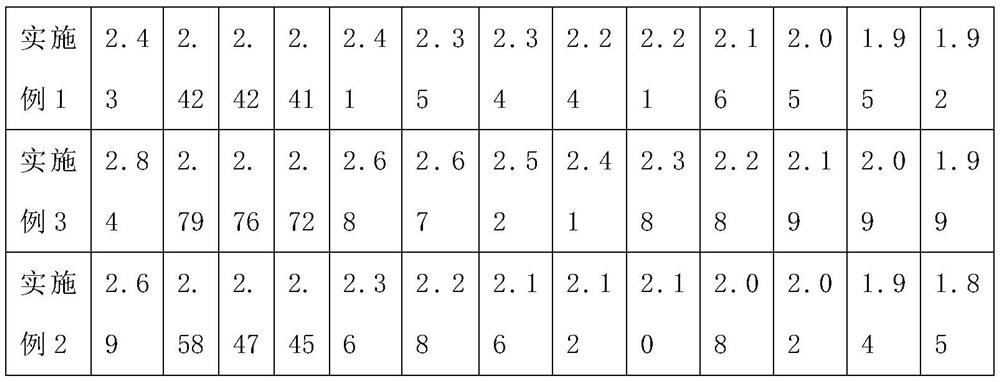

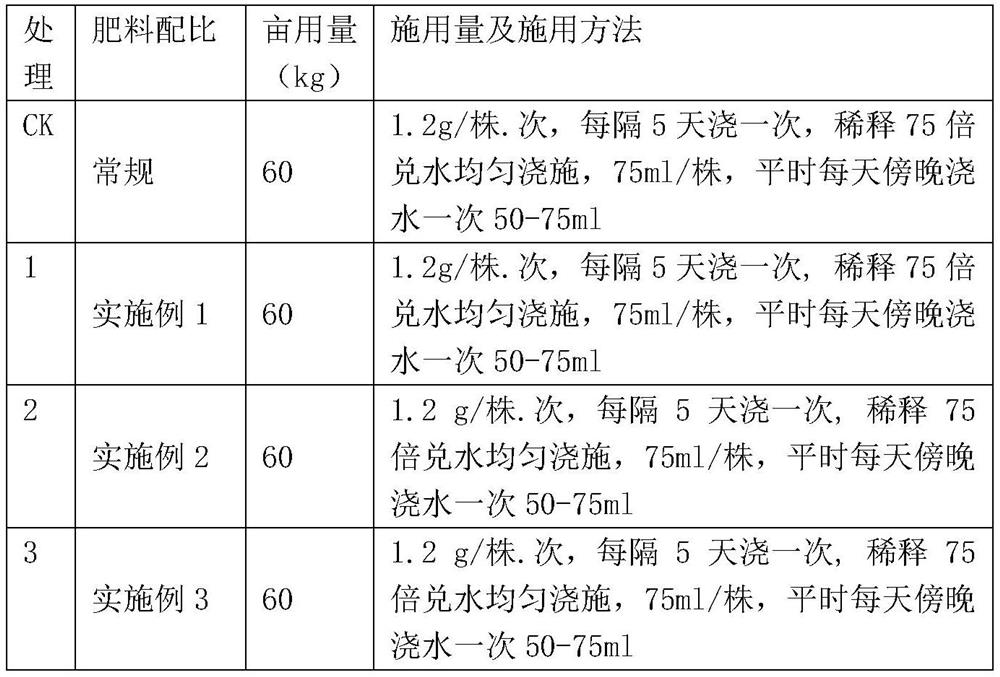

Examples

preparation example Construction

[0032] The preparation method of block biological water-soluble fertilizer:

[0033] Step 1, preparation of compound microbial agent, select Bacillus amyloliquefaciens, Bacillus licheniformis, Bacillus subtilis to inoculate into liquid biochemical potassium fulvic acid for fermentation, and obtain compound microbial bacteria with effective viable bacteria amount ≥ 2 billion / ml According to the mass concentration ratio of 1:6, the compound microbial bacterial powder is obtained by spray drying, the effective amount of viable bacteria is ≥100 billion / g (300 mesh), and it is mixed with ten polyglycerol monomyristate according to the mass ratio Mix 1:3 and set aside.

[0034] Step 2, formula formulation, using the filtered slag-removing liquid biochemical potassium fulvic acid solution, weighed and crushed and sieved ammonium nitrate, potassium nitrate, monoammonium phosphate, potassium dihydrogen phosphate, potassium sulfate, full hydrotrope, compound Microbial agent, mineral so...

Embodiment 1

[0046]100 parts of liquid biochemical potassium fulvic acid, 15 parts of mineral source potassium fulvic acid, 500 parts of ammonium nitrate, 200 parts of potassium nitrate, 5 parts of hydrotrope, 5 parts of compound microbial agent, 185 parts of monoammonium phosphate.

Embodiment 2

[0048] 150 parts of liquid biochemical potassium fulvic acid, 500 parts of ammonium nitrate, 10 parts of mineral source potassium fulvic acid, 125 parts of potassium dihydrogen phosphate, 300 parts of potassium nitrate, 5 parts of hydrotrope, 5 parts of compound functional microbial powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com