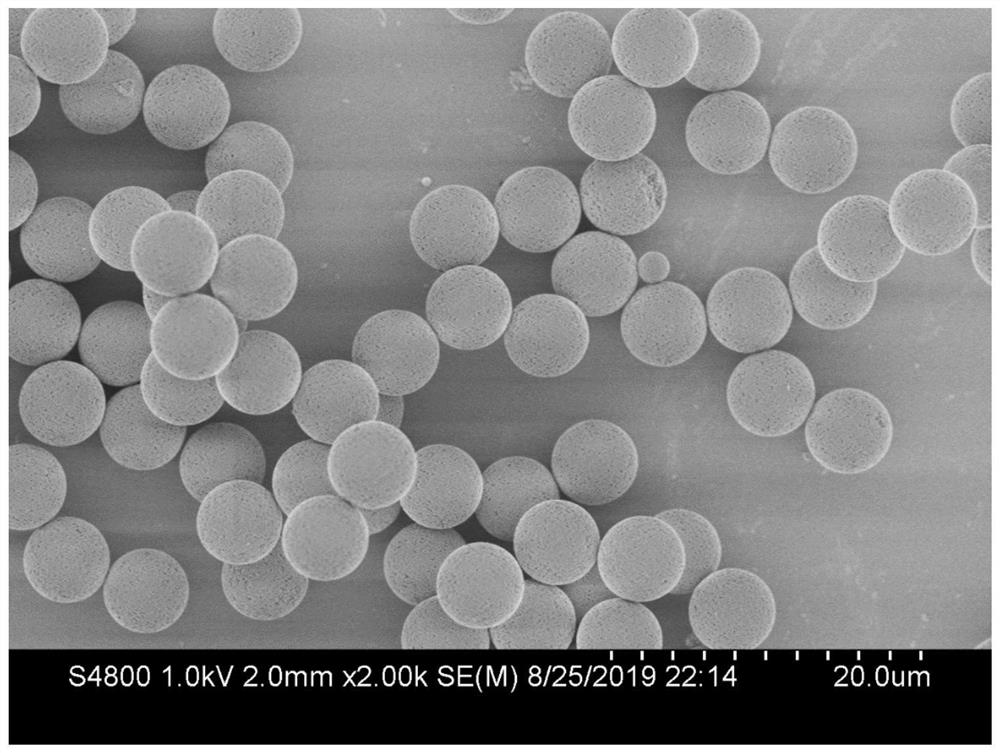

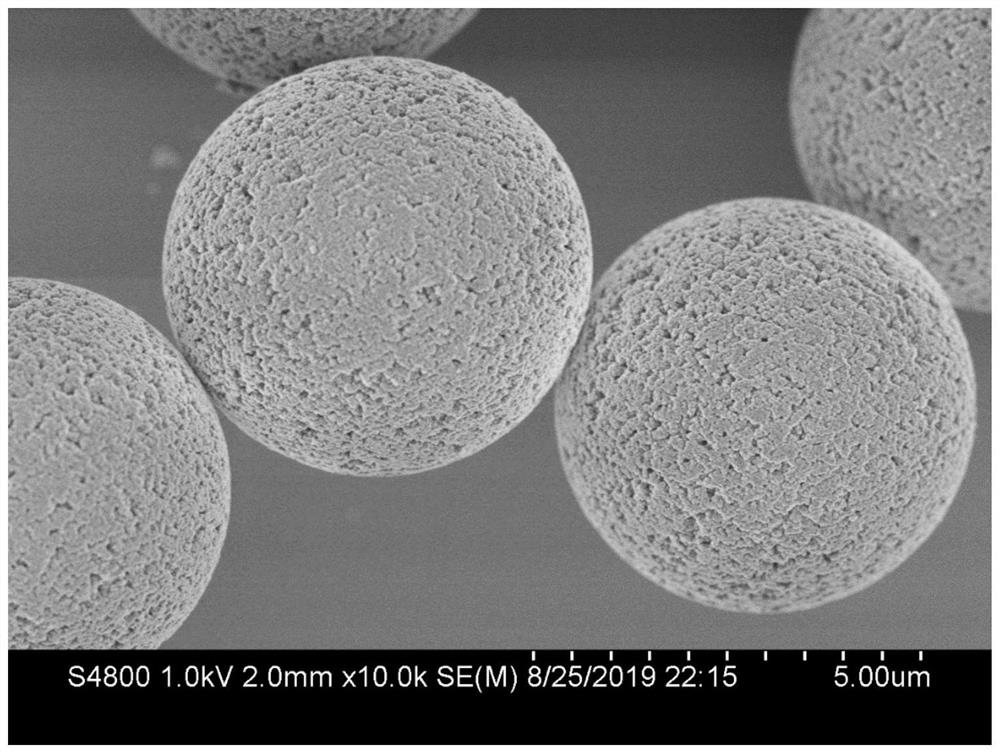

Preparation method of monodisperse magnetic polystyrene microspheres, microspheres and application thereof

A polystyrene microsphere and cross-linked polystyrene technology, which is applied in the preparation method of peptide, microsphere preparation, microcapsule preparation, etc., can solve the difficult process of magnetic polystyrene microsphere, magnetic polystyrene microsphere The problem of pellet agglomeration, affecting the magnetic application of materials, etc., achieves the effects of good dispersion, fast magnetic separation and uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of monodisperse magnetic polystyrene microspheres, comprising the following steps:

[0029] S11 prepares seed microsphere:

[0030] Weigh 4g of polyvinylpyrrolidone PVP, dissolve it in 267ml of absolute ethanol and 133ml of ultrapure water, heat to 60°C, and stir for 25min;

[0031] In addition, measure 57ml of styrene and 267mg of AIBN and mix them evenly. After ultrasonic dissolution, add them to the above solution. Under the protection of nitrogen, heat up to 65°C and react for 24h. Wash the precipitate with absolute ethanol and ultrapure water, and obtain seed microspheres after drying;

[0032] The particle size of the seed microspheres is 800-1000nm;

[0033] S12 swelling polymerization to prepare porous cross-linked polystyrene microspheres.

[0034] Measure 20ml of divinylbenzene, 40ml of toluene, and 1ml of (2-ethylhexanoic acid) tert-butyl peroxide into a glass beaker, mix well, weigh 1g of PVP and dissolve it in 100ml of 0.45% SDS solu...

Embodiment 2

[0046] A preparation method of monodisperse magnetic polystyrene microspheres, comprising the following steps:

[0047] S21 prepares seed microspheres:

[0048] Weigh 5g of polyvinylpyrrolidone PVP, dissolve in 300ml of absolute ethanol and 100ml of ultrapure water, heat to 70°C, and stir for 30min;

[0049] In addition, measure 30ml of styrene and 300mg of AIBN and mix them evenly. After ultrasonic dissolution, add them to the above solution. Under the protection of nitrogen, heat up to 75°C and react for 24h. Wash the precipitate with absolute ethanol and ultrapure water, and obtain seed microspheres after drying;

[0050] The particle size of the seed microspheres is 800-1000nm;

[0051] S22 swelling polymerization to prepare porous cross-linked polystyrene microspheres.

[0052] Measure 20ml of divinylbenzene, 40ml of toluene, and 1ml of (2-ethylhexanoic acid) tert-butyl peroxide into a glass beaker, mix well, weigh 1.5g of PVP and dissolve it in 100ml of 0.5% SDS solut...

Embodiment 3

[0061] A preparation method of monodisperse magnetic polystyrene microspheres, comprising the following steps:

[0062] S31 prepares seed microsphere:

[0063] Weigh 5.2g of polyvinylpyrrolidone PVP, dissolve in 311ml of absolute ethanol and 89ml of ultrapure water, heat to 75°C, and stir for 35min;

[0064] In addition, measure 36ml of styrene and 305mg of AIBN and mix them evenly. After ultrasonic dissolution, add them to the above solution. Under the protection of nitrogen, heat up to 80°C and react for 24h. Wash the precipitate with absolute ethanol and ultrapure water, and obtain seed microspheres after drying;

[0065] The particle size of the seed microspheres is 800-1000nm;

[0066] S32 swelling polymerization to prepare porous cross-linked polystyrene microspheres.

[0067] Measure 20ml of divinylbenzene, 40ml of toluene, and 1ml of (2-ethylhexanoic acid) tert-butyl peroxide into a glass beaker, mix well, weigh 2g of PVP and dissolve it in 100ml of 0.6% SDS solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com