Preparation method of honeycomb-like manganese-based mullite catalyst for purifying VOCs (Volatile Organic Compounds)

A mullite and honeycomb-shaped technology, which is applied in the preparation field of honeycomb-like manganese-based mullite catalysts, can solve the problems of unclear mineralization efficiency, complicated operation and explosion of manganese-based mullite catalysts, and achieve excellent low temperature The performance of catalytic oxidation of complex multi-component VOCs, the effect of cheap and easy-to-obtain raw materials, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: directly mix 10mmol manganese acetate, 5mmol samarium acetate, and 22.5mmol citric acid in solid form;

[0028] Step 2: Put the solid mixture in the step 1 into a crucible and place it in a muffle furnace;

[0029] Step 3: Raise the temperature to 750°C at a rate of 2°C / min in the muffle furnace, and maintain this temperature for 2 hours, so that the manganese acetate, samarium acetate, and citric acid in the muffle furnace fully react, and the obtained product is samarium manganese molybdenum Come stone catalyst, realize the preparation of samarium manganese mullite catalyst.

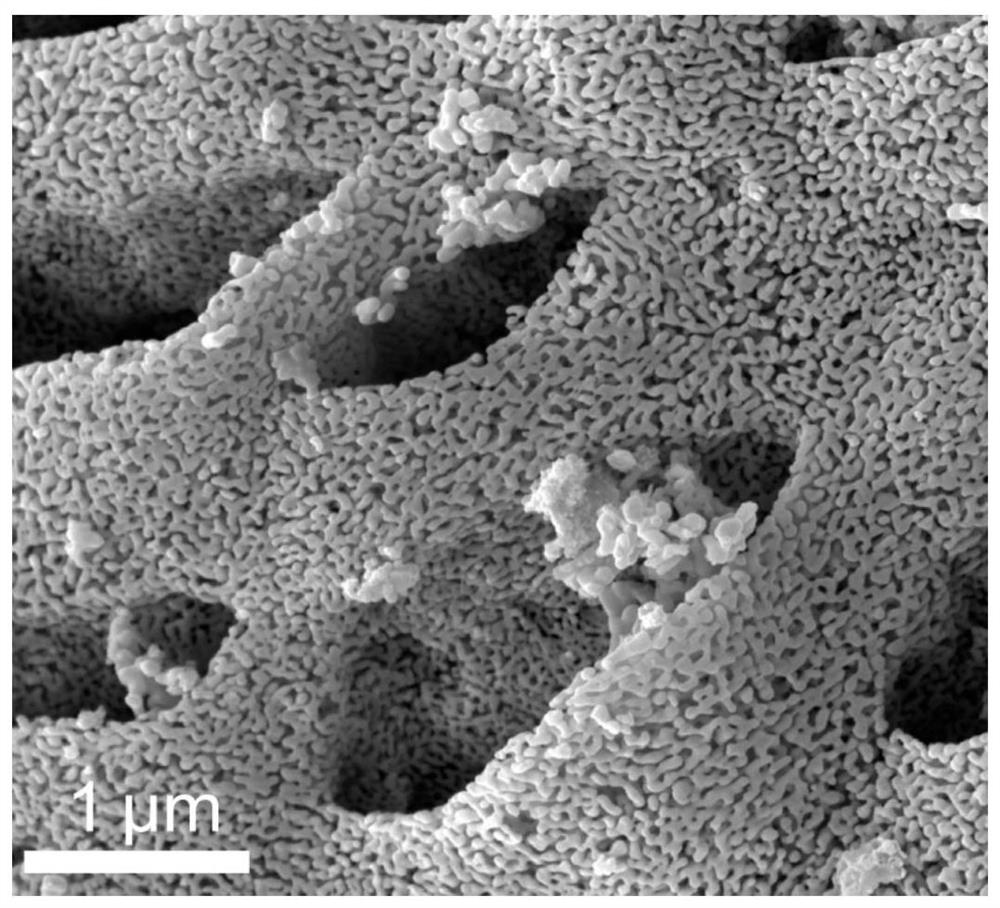

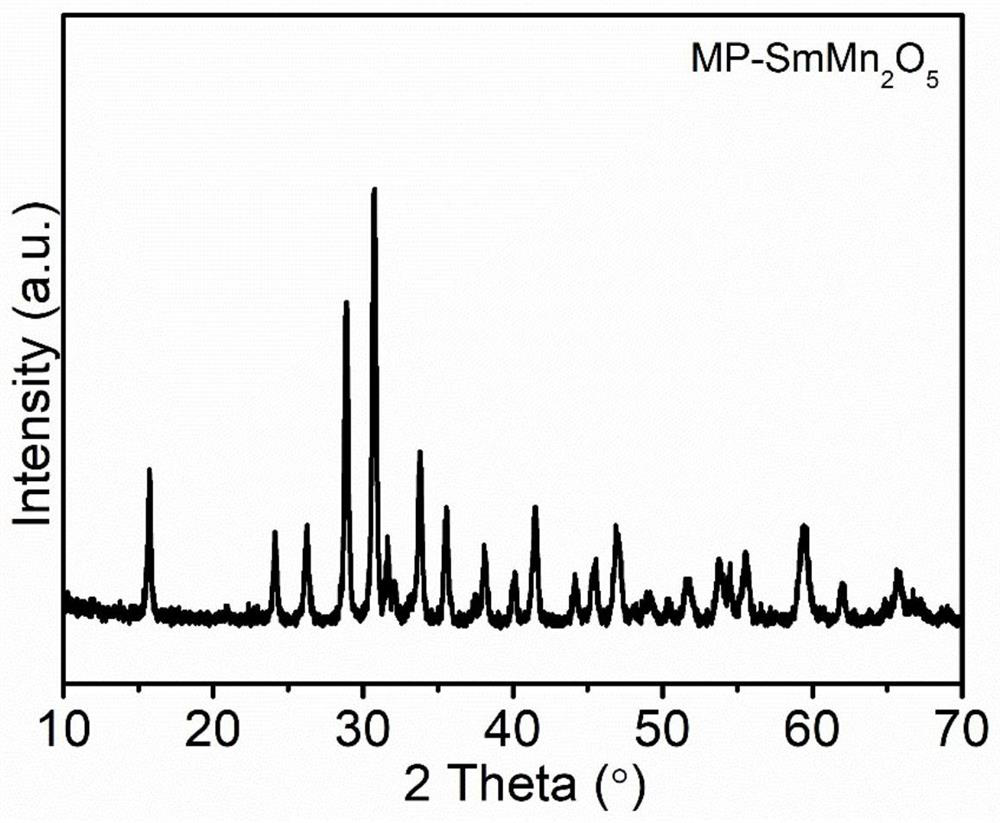

[0030] figure 1 and figure 2 They are the XRD pattern and FESEM pattern of the prepared samarium manganese mullite catalyst respectively. Characterized by FESEM, the prepared catalyst is SmMn2O5 mullite, which presents a three-dimensional connected honeycomb structure with a porous structure.

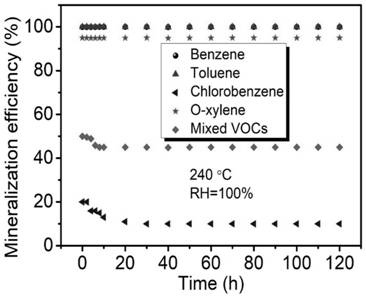

[0031] figure 2 Catalytic oxidation of 1000ppm benzene, 1000ppm toluene, 1000ppm chlorob...

Embodiment 2

[0034] Step 1: directly mix 10mmol manganese acetate, 5mmol samarium acetate, and 22.5mmol maleic acid in solid form;

[0035] Step 2: Put the solid mixture in the step 1 into a crucible and place it in a muffle furnace;

[0036] Step 3: Raise the temperature to 650° C. at a rate of 1° C. / min in a muffle furnace and maintain the temperature for 3 hours. The obtained product is samarium manganese mullite catalyst. The prepared honeycomb-like samarium manganese mullite catalyst was used for benzene oxidation, and obtained high benzene oxidation activity. The experimental results showed that: under the condition of 10000h-1 space velocity and saturated water vapor, the honeycomb-like samarium manganese mullite Stone catalytic oxidation of 1000ppm benzene, 1000ppm toluene, 1000ppm chlorobenzene, 1000ppm o-xylene, and 250ppm benzene, 250ppm toluene, 250ppm o-xylene, 250ppm chlorobenzene mixed component VOCs, the CO2 yield can reach 205℃, 188℃ respectively , 335°C, 233°C, and 346°C...

Embodiment 3

[0038] Step 1: 10 mmol of manganese acetate, 5 mmol of samarium acetate, and 22.5 mmol of ethylenediaminetetraacetic acid are directly mixed in solid form;

[0039] Step 2: Put the solid mixture in the step 1 into a crucible and place it in a muffle furnace;

[0040]Step 3: Raise the temperature to 700° C. at a rate of 3° C. / min in a muffle furnace and maintain the temperature for 3 hours. The obtained product is samarium manganese mullite catalyst. The honeycomb-like samarium-manganese mullite catalyst prepared in Example 3 was used for benzene oxidation, and higher benzene oxidation activity was obtained. The experimental results showed that: under 10000h-1 space velocity and saturated water vapor, the honeycomb-like Samarium manganese mullite catalyzes the oxidation of 1000ppm benzene, 1000ppm toluene, 1000ppm chlorobenzene, 1000ppm o-xylene, and 250ppm benzene, 250ppm toluene, 250ppm o-xylene, 250ppm chlorobenzene mixed component VOCs, and its CO2 yield reaches 210 ℃, 193...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com