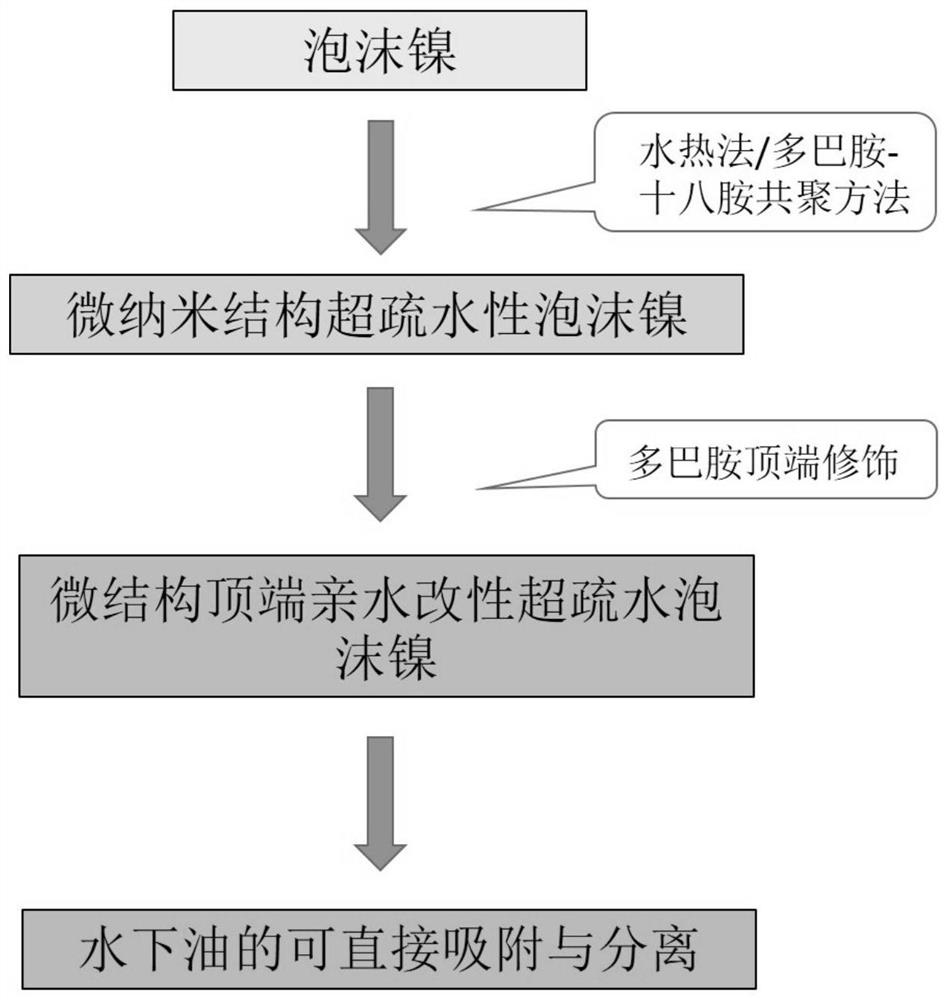

Material capable of directly adsorbing and separating underwater oil and preparation method thereof

A technology for separation and treatment of underwater oil, applied in the field of water treatment, can solve the problems of stability impact, complex method and low efficiency, and achieve the effect of strong underwater stability, simple method and no noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

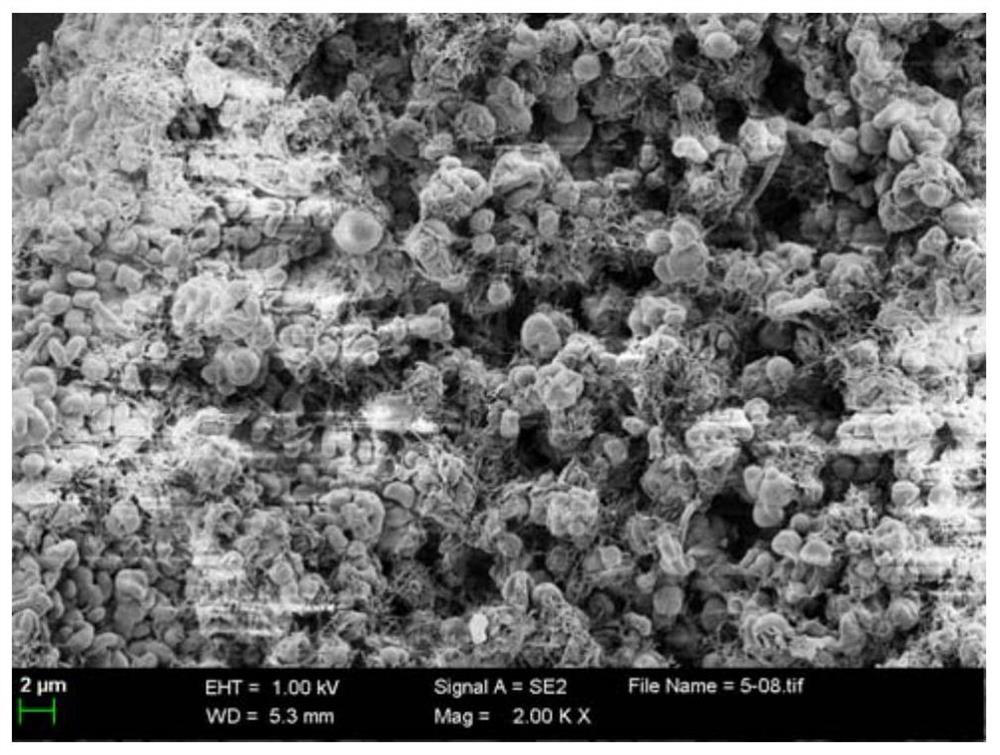

[0031] (1) The foamed nickel was ultrasonically treated with an aqueous solution of hydrochloric acid of 2mol / L for 20 minutes, then repeatedly ultrasonically cleaned with deionized water for 2 times and then dried for subsequent use; prepare 18.0mM cobalt nitrate hexahydrate, 30.0mM urea, 90.0 The ethylene glycol / water solution of mM ammonium fluoride, wherein the volume ratio of ethylene glycol and water is 1:3; Put the foamed nickel after the above-mentioned pretreatment and preparation solution into tetrafluoroethylene to be the reactor of liner, at 160 React for 16 hours under the condition of ℃, take out after the reaction; wash with deionized water and dry to obtain foamed nickel treated by hydrothermal method.

[0032] (2) prepare the ethanol / water solution of 2.0g / L dopamine and 5.0mM octadecylamine, wherein the volume ratio of ethanol and water is 1:1; Regulate pH to 8.5 with Tris-HCL; Move it into the preparation solution and react for 24 hours; after the reaction, ...

Embodiment 2

[0035] (1) The hydrochloric acid aqueous solution that foamed nickel is used mass fraction is 2mol / L carries out sonication for 20 minutes, after repeated supersonic cleaning 2 times with deionized water, dry for subsequent use; prepare 12.0mM cobalt nitrate hexahydrate, 20.0mM urea, 71.0 The ethylene glycol / water solution of mM ammonium fluoride, wherein the volume ratio of ethylene glycol and water is 1:3; Put the foamed nickel after the above-mentioned pretreatment and preparation solution into tetrafluoroethylene to be the reactor of liner, at 140 React for 24 hours under the condition of ℃, take out after the reaction; wash with deionized water, and dry to obtain foamed nickel treated by hydrothermal method.

[0036] (2) prepare the ethanol / water solution of 1.2g / L dopamine and 5.0mM octadecylamine, wherein the volume ratio of ethanol and water is 1:1; Regulate pH to 8.5 with Tris-HCL; Move it into the preparation solution and react for 24 hours; after the reaction, the n...

Embodiment 3

[0039] (1) The hydrochloric acid aqueous solution that the mass fraction is 2mol / L is carried out supersonic treatment 20 minutes to nickel foam, after repeated supersonic cleaning 2 times with deionized water, dry for subsequent use; prepare 20.0mM cobalt nitrate hexahydrate, 35.0mM urea, 98.0 The ethylene glycol / water solution of mM ammonium fluoride, wherein the volume ratio of ethylene glycol and water is 1:3; Put the foamed nickel after the above-mentioned pretreatment and preparation solution into tetrafluoroethylene as the reactor of liner, at 180 React under the condition of ℃ for 18 hours, take out after the reaction; wash with deionized water and dry to obtain foamed nickel treated by hydrothermal method.

[0040] (2) prepare the ethanol / water solution of 2.8g / L dopamine and 10.0mM octadecylamine, wherein the volume ratio of ethanol and water is 1:1; Regulate pH to 8.5 with Tris-HCL; Move it into the preparation solution and react for 24 hours; after the reaction, th...

PUM

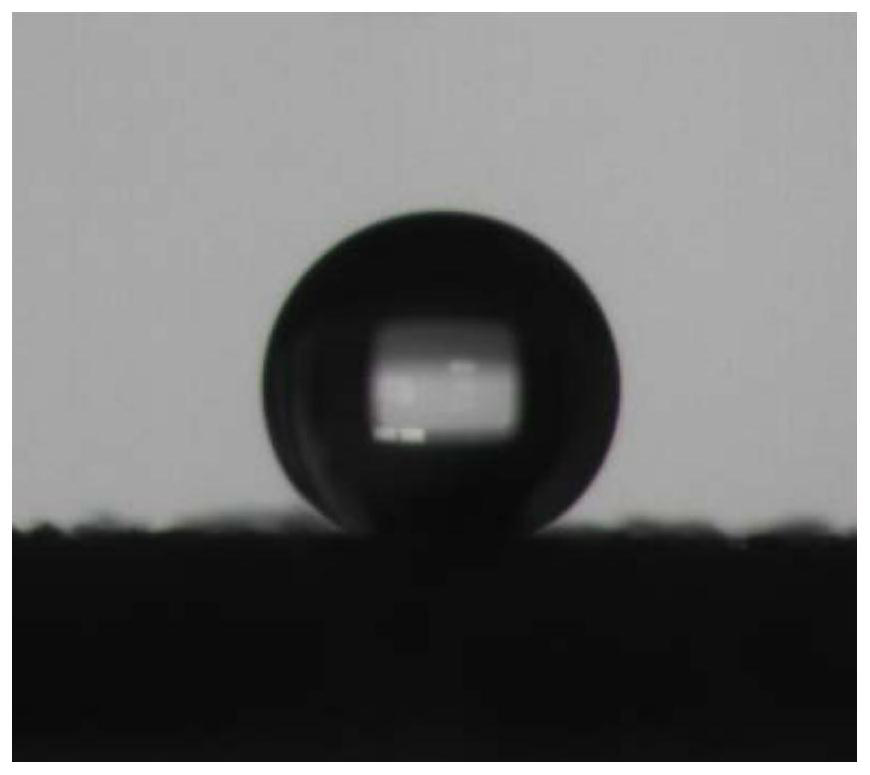

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com