ULDPE-containing multi-layer co-extrusion disposable biotechnological bag membrane material and preparation method thereof

A one-time, membrane technology, applied in the directions of biochemical equipment and methods, chemical instruments and methods, bags, etc., can solve the problem of water resistance, bending resistance and puncture resistance. effect, the processing cost of bioprocess bags, etc., to achieve the effect of good biocompatibility, good cell culture effect, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

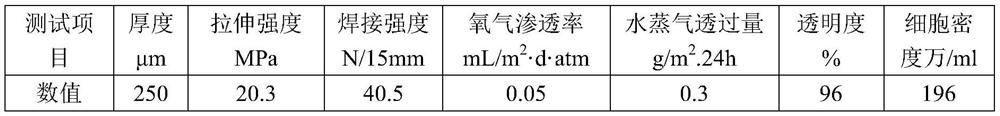

[0061] Embodiment 1 adopts the film material for disposable biotechnology bags containing ULDPE prepared by co-extrusion blow molding method

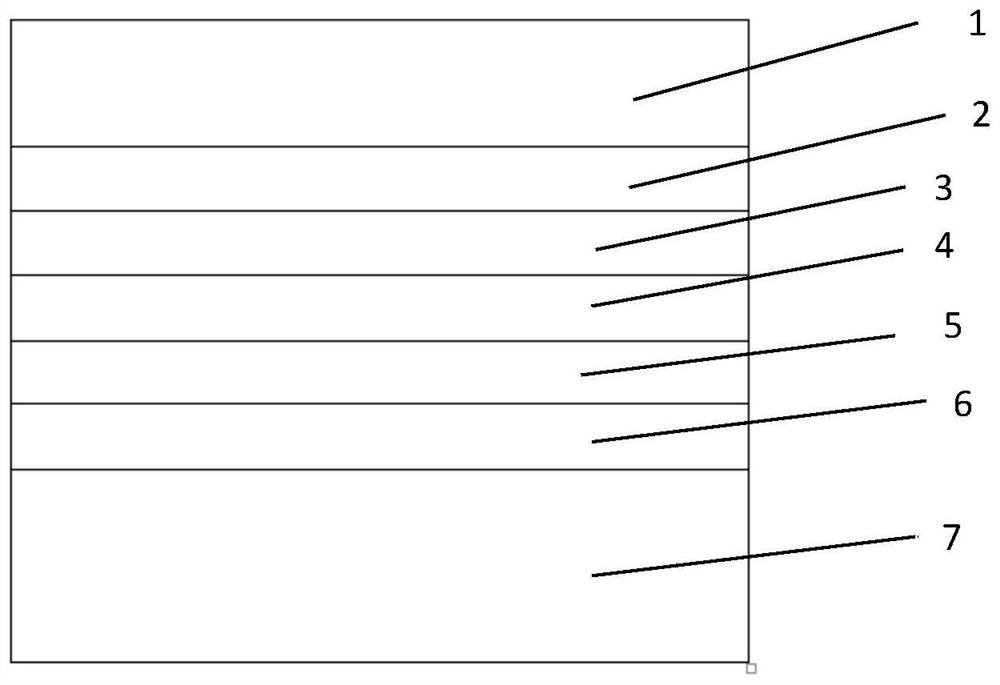

[0062] In this example, the co-extrusion blow molding method is used to prepare a film material for a disposable biotechnology bag with a thickness of 250 μm. The composition of the film material includes the following figure 1 As shown, it includes heat seal layer 1, adhesive layer 2, gas barrier layer 3 / 4 / 5, adhesive layer 6 and liquid contact layer 7.

[0063] Among them, the heat-sealing layer LDPE adopts the Dow series of Dow, and the thickness of this layer is 50 μm.

[0064] The adhesive layers 2 and 6 are made of Dow Chemical Primacor resin with a thickness of 5 μm.

[0065] The gas barrier layers 3 and 5 are aromatic PA, which are made by American DuPont, and the thickness of the layers is 15 μm.

[0066] The gas barrier layer 4 is EVOH using Kuraray EVAL resin, and the thickness of this layer is 10 μm.

[0067] The ULDPE o...

Embodiment 2

[0079] Example 2 The membrane material for the disposable biotechnology bag containing ULDPE prepared by co-extrusion casting method

[0080] The composition and structure of the disposable bioprocess bag membrane material containing ULDPE provided by the present embodiment is as follows: figure 1 As shown, it includes heat seal layer 1, adhesive layer 2, gas barrier layer 3 / 4 / 5, adhesive layer 6 and liquid contact layer 7.

[0081] In this example, the co-extrusion casting method is used to prepare a disposable biotechnology bag film material with a thickness of 400 μm;

[0082] Heat-sealing layer 1 adopts the EVA of Celanese company, and the thickness of this layer is 100 μ m;

[0083] Adhesive layers 2 and 6 use Yangzi Petrochemical EVA with a thickness of 10 μm;

[0084] The gas barrier layers 3 and 5 on both sides are EVOH of the Kuraray EVAL series, with a thickness of 30 μm;

[0085] The intermediate gas barrier layer 4 is made of aromatic PA of the relevant brand o...

Embodiment 3

[0094] Embodiment 3 adopts the impact of different gas barrier layers on the performance of disposable bioprocess bags

[0095] In this example, the method provided in Example 2 is used to prepare a disposable biotechnology bag film material with a total thickness of 400 μm, and different gas barrier layers as shown in Table 5 are used respectively, where the thickness is the thickness of the gas barrier layer, The oxygen, water vapor permeability, tensile strength, transparency and cell culture effect (biocompatibility) of the prepared multilayer co-extruded disposable bioprocess bag membrane were investigated.

[0096] EVOH adopts Kuraray EVAL series, PA adopts aromatic PA, aliphatic PA, and aliphatic-aromatic PA of DuPont related brands in the United States, and PE uses related brands of Dow Company in the United States.

[0097] Among them, the oxygen, water vapor permeability, tensile strength, welding strength, transparency and cell culture effect detection methods are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com