A kind of nano-recycled concrete, processing technology and application

A technology of recycled concrete and processing technology, applied in additive processing, manufacturing tools, construction, etc., can solve problems such as difficulty in guaranteeing water retention, cohesion, mechanical toughness and volume stability, poor use effect, and inability to use, to ensure Effects of marine durability, good interfacial adhesion, good thixotropy and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

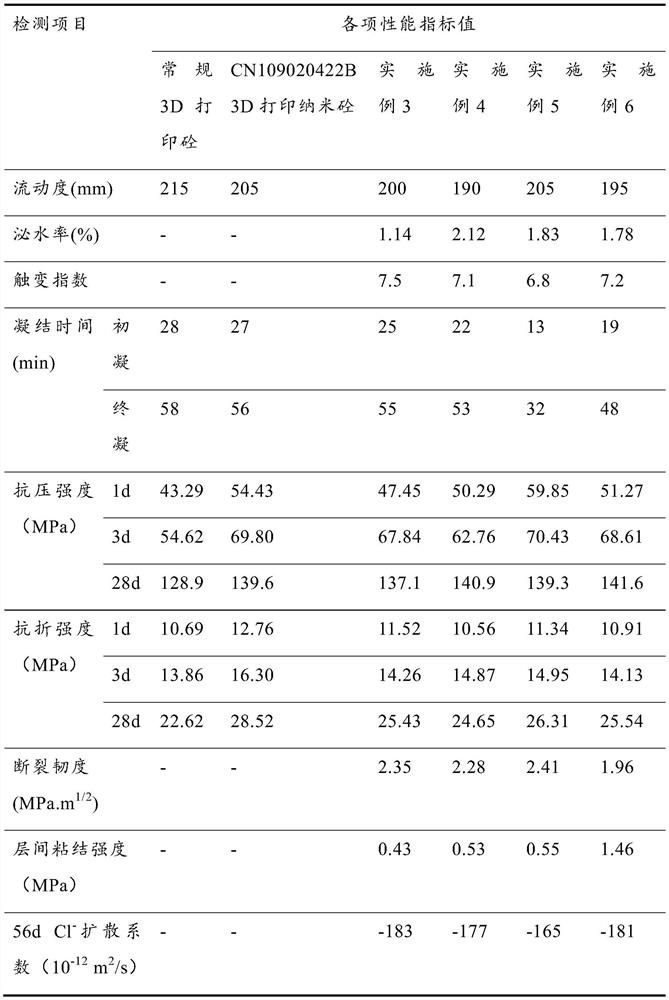

Embodiment 1

[0068] In the present embodiment, a nano-regenerated concrete is provided, and the nano-regenerated concrete includes the following components: compound cement, recycled sand, fly ash (FA), polyvinyl alcohol (PVA), graphene oxide (GO) , steel fiber, organic fiber, water reducer, coagulation regulator, mineral admixture and water; the mass ratio of the above components is 1:1:0.05:0.005:0.0002:0.01:0.005:(0.005-0.01): 0.005:0.01:0.3.

[0069] Among them, the compound cement includes the following components: high belite sulfoaluminate cement (HBSC), Portland cement, gypsum, the mass ratio of each component is 1:0.65:0.1; the compound cement has fast setting early strength The characteristics and the ball lubrication characteristics of FA contribute to the realization of the printable and buildable functions of the corresponding nano-recycled concrete.

[0070] The mass ratio of coarse sand, medium sand, fine sand and ultrafine sand in the regenerated sand is 1:1.1:1:1.

[007...

Embodiment 2

[0082] In the present embodiment, a nano-regenerated concrete is provided, and the nano-regenerated concrete includes the following components: compound cement, recycled sand, fly ash (FA), polyvinyl alcohol (PVA), graphene oxide (GO) , steel fiber, organic fiber, water reducer, coagulant, mineral admixture and water; the mass ratio of the above components is 1:2:0.2:0.05:0.002:0.05:0.02:0.01:0.01:0.05: 0.5.

[0083] Among them, the compound cement includes the following components: high belite sulfoaluminate cement (HBSC), Portland cement, and gypsum, and the mass ratio of each component is 1:1.25:0.15.

[0084] The mass ratio of coarse sand, medium sand, fine sand and ultrafine sand in the regenerated sand is 1:2.0:1.5:1.5.

[0085] The FA is Class I FA with a loss on ignition ≤ 5% specified in the GB / T 1596-2017 standard.

[0086] The PVA is a PVA aqueous solution with an average polymerization degree of 500-600 and an alcoholysis degree of 88%; the GO is dispersed in the...

Embodiment 3

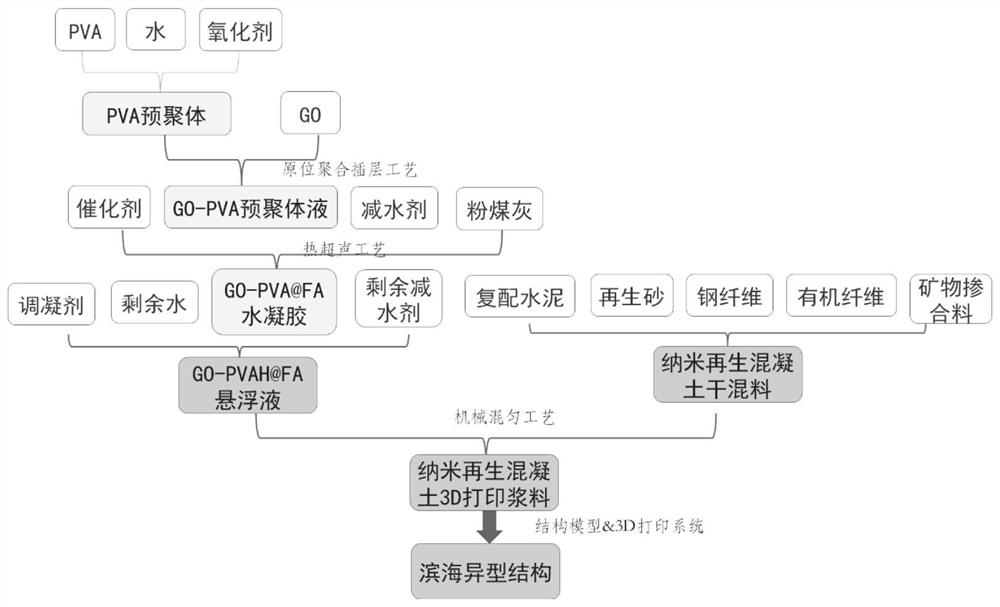

[0096] In the present embodiment, a processing technology of nano-regenerated concrete is provided, which specifically includes the following steps:

[0097] S1: Dissolve 0.25kg of PVA in 5L of hot water at a temperature of 70°C to prepare a PVA aqueous solution with a concentration of 5%, an average degree of polymerization of 500-600, and a degree of alcoholysis of 88%; Under the condition of sodium acid (PVA oxidant), 0.025kg GO powder was mixed into the above-mentioned PVA aqueous solution, and the in-situ polymerization intercalation process was used to intercalate the PVA prepolymer in the GO sheet structure to obtain the GO-PVA prepolymer liquid.

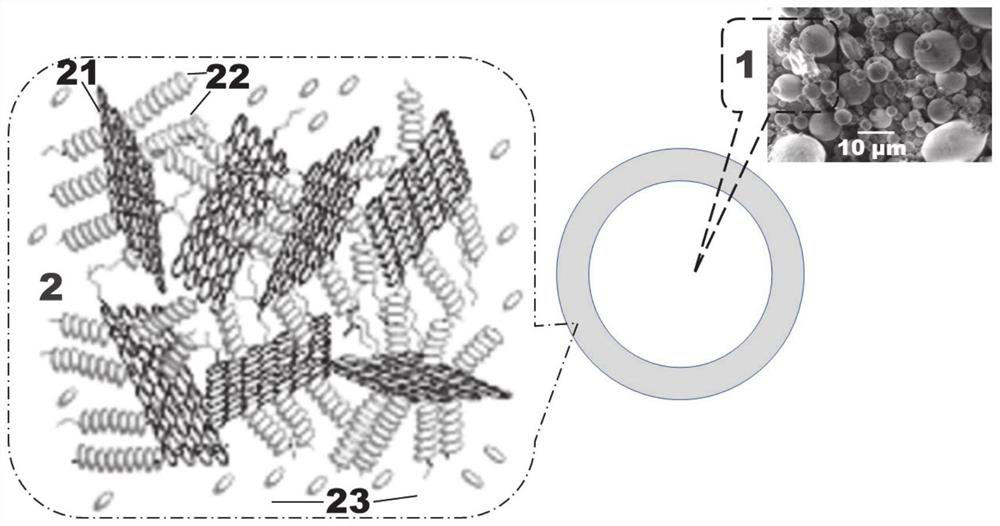

[0098] S2: Add 1.0kg of FA, 0.1kg of polycarboxylate superplasticizer, and 0.01kg of concentrated hydrochloric acid (PVA catalyst) to the above-mentioned GO-PVA prepolymer liquid, and further adopt an oil bath thermosonic dispersion process (oil temperature 100°C , frequency 10kHz, power 50W, ultrasonic time 30min), wrap GO-P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com