Method for recovering methane production performance of anaerobic fermentation acid inhibition system by using photosynthetic bacteria

A technology of anaerobic fermentation and photosynthetic bacteria, applied in microorganism-based methods, fermentation, bacteria, etc., can solve the problems of complex composition of microbial agents, narrow recovery range, long recovery time, etc., to improve sewage treatment efficiency and reproduction speed. Fast, quick release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

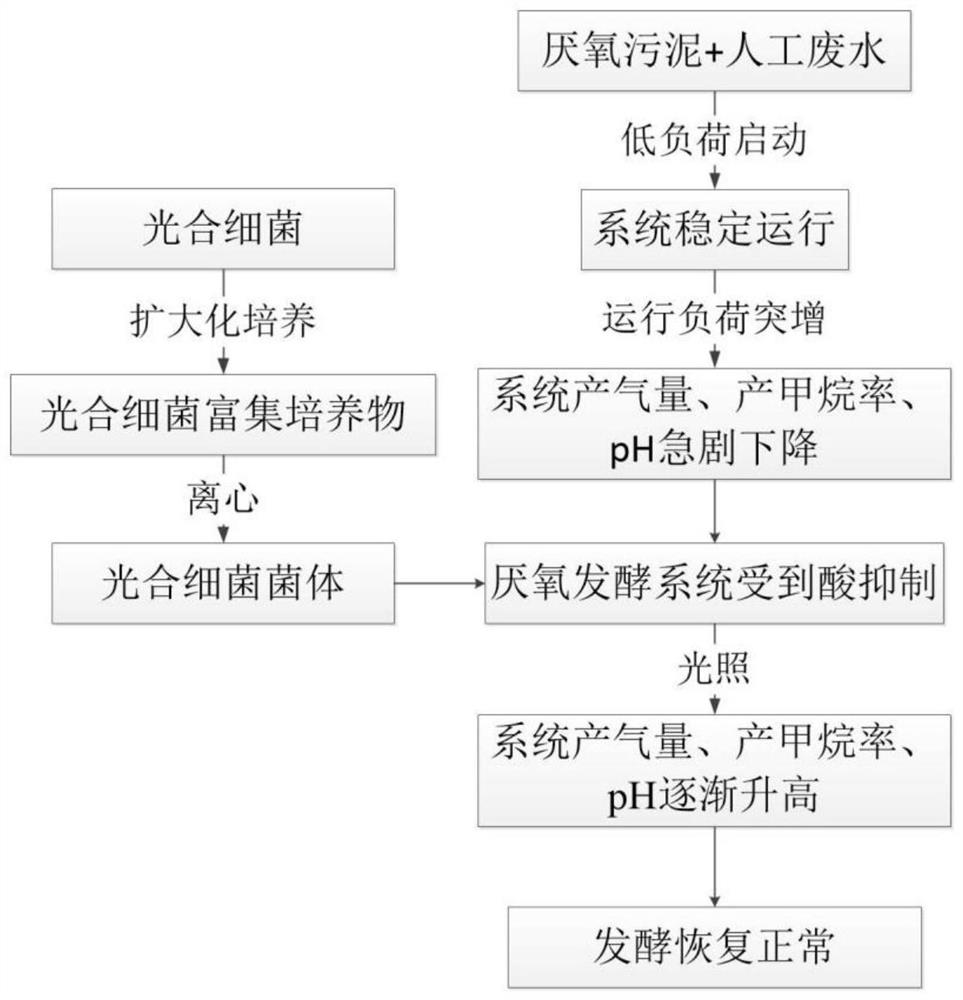

[0034] The invention provides a method for utilizing photosynthetic bacteria to restore the methanogenic performance of the anaerobic fermentation acid inhibition system, the process flow chart is as follows figure 1 As shown, the specific implementation is as follows:

[0035] (1) Cultivation of photosynthetic bacteria: use the improved RCVBN medium to enrich and cultivate the photosynthetic bacteria purchased on the market. After about 7-10 days, a large number of microbial cells were obtained, centrifuged at 12000r for 1min, and the supernatant was removed. Obtain photosynthetic bacteria cells.

[0036] (2) Start the reactor and simulate acidification conditions: use the anaerobic tower sludge of a brewery sewage treatment station as inoculation sludge, use 500mL blue cap bottle as anaerobic batch reactor, inoculate artificial simulated wastewater, and use 1000 mg COD The low load of / L / d starts three groups of the same reactors, and the gas production rate and methane pro...

Embodiment 2

[0040] Cultivation of photosynthetic bacteria: Use the improved RCVBN medium to enrich and cultivate the photosynthetic bacteria purchased in the market. After about 7 days, a large number of microbial cells were obtained, centrifuged at 12000r for 1min, and the supernatant was removed to obtain photosynthetic bacteria cells .

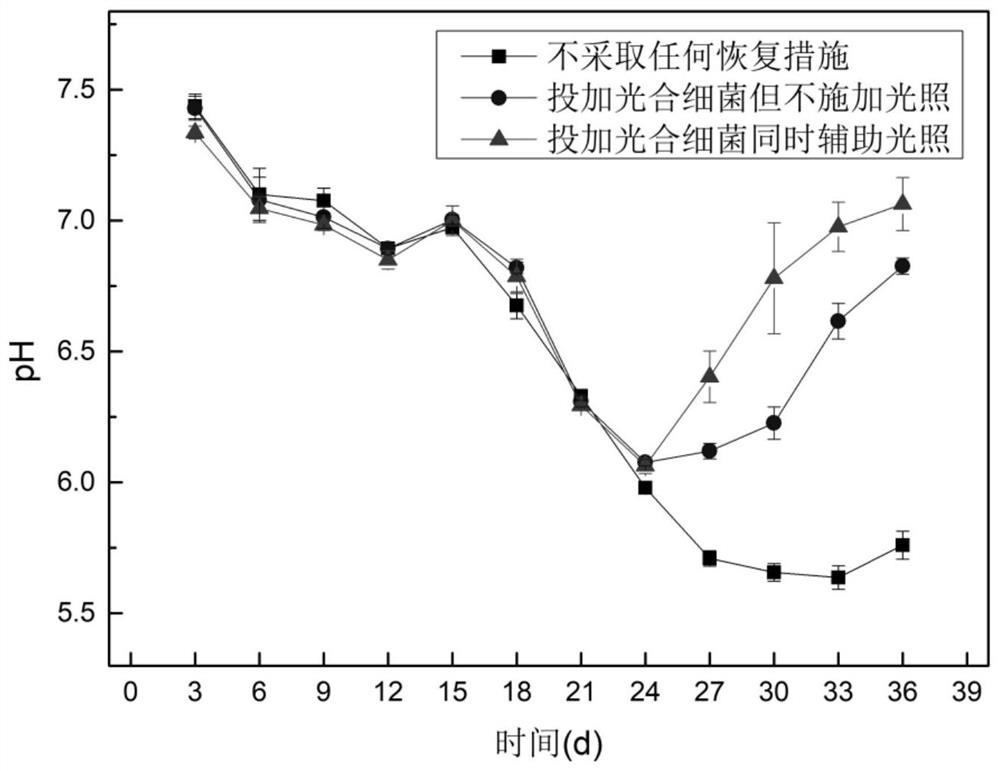

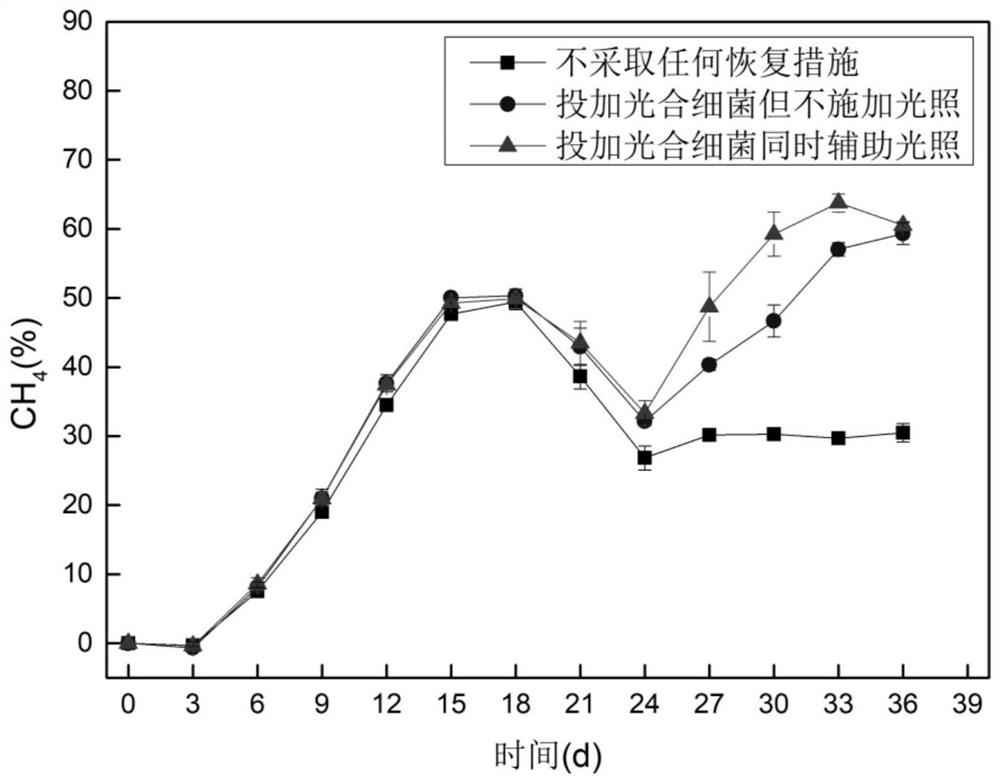

[0041] Start the reactor to simulate acidification conditions: use the anaerobic tower sludge of a brewery sewage treatment station as the inoculation sludge, use 1000mL blue cap bottle as the anaerobic batch reactor, inoculate artificial simulated wastewater, and use 1200mg COD / L / d Three groups of the same reactors were started at a low load, and the gas production rate and methane production rate increased slowly. After about 18 days, the reactor reached a stable operating state, and the organic load was increased to 6000mg COD / L / d, such as figure 2 As shown in Figure 4, the pH of the reactor dropped sharply to about 6.0, the methane production rat...

Embodiment 3

[0045] Cultivation of photosynthetic bacteria: The photosynthetic bacteria purchased in the market were enriched and cultivated with beer wastewater. After about 10 days, a large number of microbial cells were obtained, centrifuged at 13000r for 1min, and the supernatant was removed to obtain photosynthetic bacteria cells.

[0046] Start the reactor to simulate acidification conditions: using anaerobic sludge from an industrial wastewater treatment station as inoculation sludge, three sets of the same UASB reactors were used to treat high-concentration organic wastewater. After about 18 days, the reactor reached a stable operating state. At this time, the organic load suddenly increases, such as Figure 2 ~ Figure 4 As shown, the pH of the reactor dropped sharply to about 6.0, the methane production rate decreased to 30%, the corresponding gas production also decreased significantly, and the system was obviously acidified.

[0047] Dosing photosynthetic bacteria for recovery: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com