Phthalocyanine catalyst for dye wastewater treatment and preparation method thereof

A dye wastewater and catalyst technology, which is applied in physical/chemical process catalysts, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of burden and the generation of harmful substances, and achieve a simple method, low cost and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

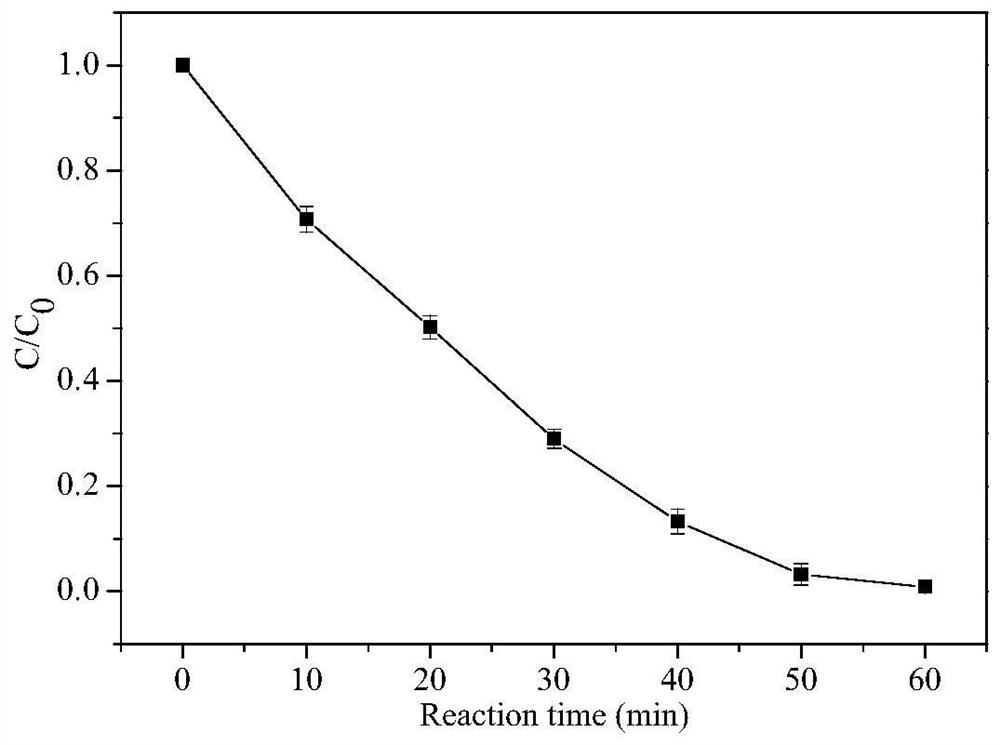

Embodiment 1

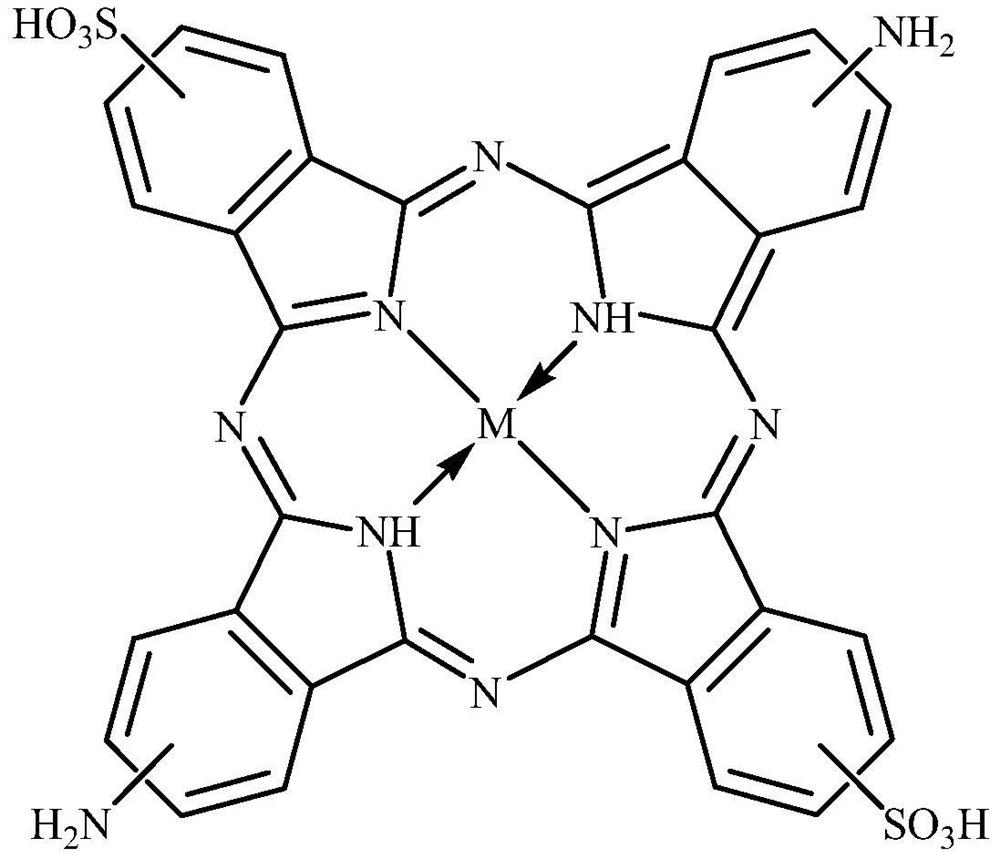

[0029] A preparation method for a phthalocyanine catalyst for dye wastewater treatment, comprising the following steps:

[0030] (1) Weigh 2.50g sulfamate cobalt phthalocyanine, 12.00g glucose, 1.25g peptone, 1.25g yeast extract and 0.10g disodium hydrogen phosphate, dissolve them in 100mL ultrapure water, and prepare the first mixture solution.

[0031] (2) Add Gluconacetobacter intermedia to the first mixed solution obtained in step (1), and culture at 30° C. for 5 days.

[0032] (3) Weigh 2.00g of silver nitrate, 6.00g of glucose, 0.50g of peptone, 0.50g of yeast extract and 0.05g of disodium hydrogen phosphate, and dissolve them in 100mL of ultrapure water to prepare a second mixed solution.

[0033] (4) Put the product obtained in step (2) into the second mixed solution obtained in step (3), add Gluconacetobacter intermedius, and react at 30° C. for 24 hours.

[0034] (5) Wash the product obtained in step (4) successively with 0.50mol / L hydrochloric acid, 0.50mol / L sodi...

Embodiment 2

[0047] A preparation method for a phthalocyanine catalyst for dye wastewater treatment, comprising the following steps:

[0048] (1) Weigh 5g sulfamate-based cobalt phthalocyanine, 15.00g glucose, 2.00g peptone, 2.00g yeast extract and 0.20g disodium hydrogen phosphate, dissolve them in 100mL ultrapure water, and prepare the first mixed solution .

[0049] (2) Acetobacter xylinum was added to the first mixed solution obtained in step (1), and cultured at 30° C. for 5 days.

[0050] (3) Weigh 4.00g of silver nitrate, 10.00g of glucose, 1.00g of peptone, 1.00g of yeast extract and 0.10g of disodium hydrogen phosphate, and dissolve them in 100mL of ultrapure water to prepare a second mixed solution.

[0051] (4) Put the product obtained in step (2) into the second mixed solution obtained in step (3), add Acetobacter xylinum, and react at 30° C. for 24 hours.

[0052] (5) Wash the product obtained in step (4) successively with 0.50mol / L hydrochloric acid, 0.50mol / L sodium hydrox...

Embodiment 3

[0056] A preparation method for a phthalocyanine catalyst for dye wastewater treatment, comprising the following steps:

[0057] (1) Weigh 5g sulfamate-based cobalt phthalocyanine, 15.00g glucose, 2.00g peptone, 2.00g yeast extract and 0.20g disodium hydrogen phosphate, dissolve them in 100mL ultrapure water, and prepare the first mixed solution .

[0058] (2) Acetobacter xylinum was added to the first mixed solution obtained in step (1), and cultured at 30° C. for 5 days.

[0059] (3) Weigh 0.10 g of silver nitrate, 10.00 g of glucose, 1.00 g of peptone, 1.00 g of yeast extract and 0.10 g of disodium hydrogen phosphate, and dissolve them in 100 mL of ultrapure water to prepare a second mixed solution.

[0060] (4) Put the product obtained in step (2) into the second mixed solution obtained in step (3), add Acetobacter xylinum, and react at 30° C. for 24 hours.

[0061] (5) Wash the product obtained in step (4) successively with 0.50mol / L hydrochloric acid, 0.50mol / L sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com