Multi-axis laser scanning optical system

A laser scanning and optical system technology, applied in the field of laser processing, can solve problems such as the quality degradation of the laser focus, limiting the processing width and aspect ratio, and limiting the adjustment speed of the lens spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

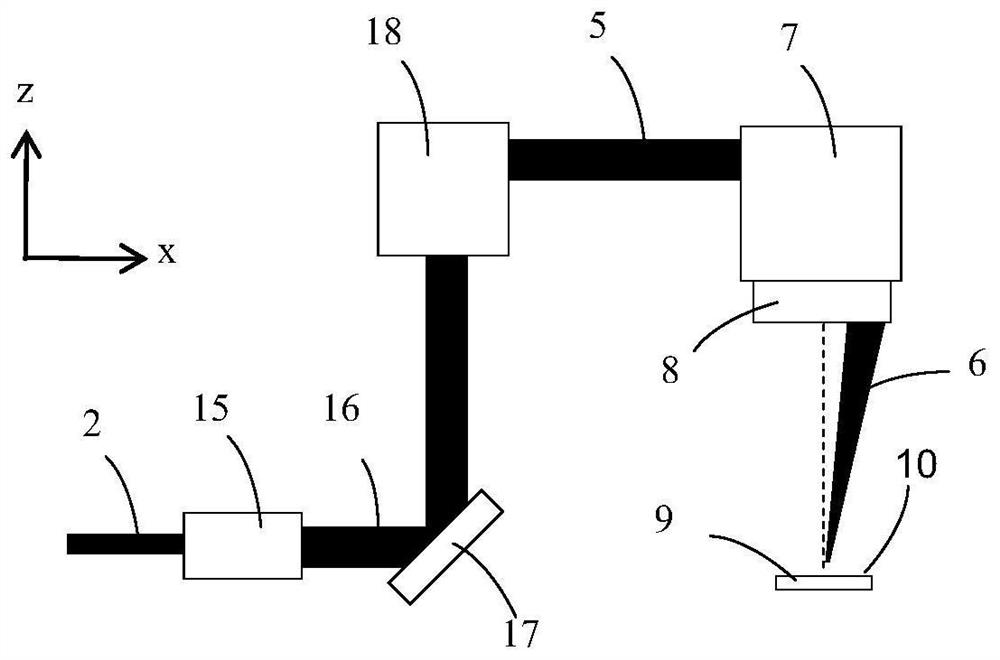

[0070] Example 1: Large-scale high-precision etching of superalloy plates with multi-axis laser scanning optical system

[0071] A laser with an average power of 60W, a wavelength of 1064nm, and a pulse length of 10ps is used as a light source, the repetition frequency is selected as 200kHz, and the material to be processed is a 50x50x2mm superalloy flat plate. The diameter of the incident laser beam 2 is 6mm, the diameter of the high dynamic lens 19 in the dynamic focusing module 15 is 7mm, the maximum inclination angle of the scanning laser beam is 7°, the scanning range of the two-dimensional scanning module 7 is 50x50mm, and the multi-axis system follows the planned path on the surface of the material The corresponding three-dimensional shape is etched to realize high-efficiency three-dimensional etching processing without flanging in large format.

example 2

[0072] Example 2: Manufacture of multi-axis laser scanning optical system with large depth-to-diameter ratio and large format group holes

[0073] A laser with a maximum average power of 20W and a wavelength of 355nm is used as a light source, the pulse width is set to 100ns, the repetition frequency is selected to be 200kHz, and the material to be processed is a titanium alloy plate with a thickness of 500μm. The diameter of the incident laser beam 2 is 0.8mm, the diameter of the high dynamic mirror 19 in the dynamic focusing module 15 is 1mm, the inclination angle of the scanning laser beam is 2°, and the two-dimensional scanning module 7 is in a square format of 10x10mm, with a radius of 50μm. It is the scanning unit and the distance between the centers of the circles is 150 μm to scan the array circle. Under the control of the dynamic focus module 15, the laser focus moves to the bottom of the material at a speed of 50 μm / s, so that the laser focus is always located on the ...

example 3

[0074] Example 3: Special-shaped cutting of large-sized copper plates with multi-axis laser scanning optical system

[0075] A laser with a maximum average power of 200W and a wavelength of 1064nm is used as a light source, the pulse width is set to 100ns, and the repetition frequency is selected to be 200kHz. The material to be processed is a copper plate with a thickness of 1000μm. The diameter of the incident laser beam 2 is 3 mm, the diameter of the high dynamic mirror 19 in the dynamic focusing module 15 is 4 mm, the inclination angle of the scanning laser beam is 3 °, the scanning pattern of the two-dimensional scanning module 7 is a square of 100x100 mm, the inclination angle of the laser beam As the different sides of the square change, under the control of the dynamic focus module 15, the laser focus moves to the bottom of the material at a speed of 50 μm / s, so that the laser focus is always located on the surface of the copper plate, and the side wall of the square wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com