Anti-reflection coating solution suitable for double-layer coating and its preparation method and application

A coating solution and anti-reflection technology, applied in coating, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems affecting the power generation of photovoltaic modules, achieve excellent dirt resistance and weather resistance, moderate porosity, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of broadband high anti-reflection double-layer coating anti-reflection coating solution for photovoltaic glass of the present invention, wherein the preparation method of the bottom coating solution is as follows:

[0044] 1) Preparation of silane polymer in bottom coating solution:

[0045] 1.1) Preparation of silane polymer: Add 30 parts of ethyl orthosilicate, 5 parts of methyltriethoxysilane, 60 parts of isopropanol, 13 parts of water, and 0.01 part of nitric acid into the reaction kettle while stirring, and start Heating, be warming up to 60 DEG C, react 4h, cool down after reaction finishes, for subsequent use.

[0046] 1.2) Preparation of bottom coating solution:

[0047] In terms of parts by mass, 25 parts of the above-mentioned silane polymer, 2 parts of propylene glycol methyl ether acetate, and 54 parts of isopropanol were added while stirring, and the materials were mixed evenly by stirring to obtain the bottom layer coating solution.

[0048] 2) Th...

Embodiment 2

[0057] A kind of broadband high anti-reflection double-layer coating anti-reflection coating solution for photovoltaic glass of the present invention, wherein the preparation method of the bottom coating solution is as follows:

[0058] 1) Preparation of silane polymer for bottom coating solution:

[0059] 1.1) Preparation of silane polymer: Add 40 parts of tetraethyl orthosilicate, 76 parts of isopropanol, 16 parts of water, and 0.05 parts of hydrochloric acid into the reactor in turn while stirring, turn on the heating and raise the temperature to 50°C, react for 5 hours, and react When finished, cool down and set aside.

[0060] 1.2) Preparation of bottom coating solution:

[0061] According to mass percentage, 30 parts of the above-mentioned silane polymer, 62 parts of isopropanol and 4 parts of propylene glycol butyl ether were added while stirring, and the materials were mixed evenly, and discharged to obtain the bottom layer coating solution.

[0062] 2) The preparati...

Embodiment 3

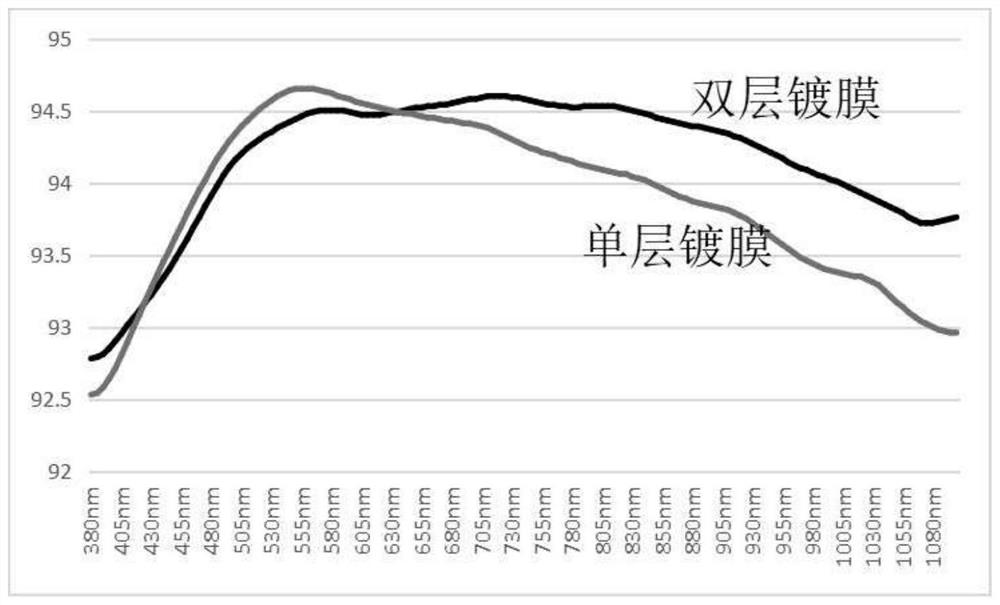

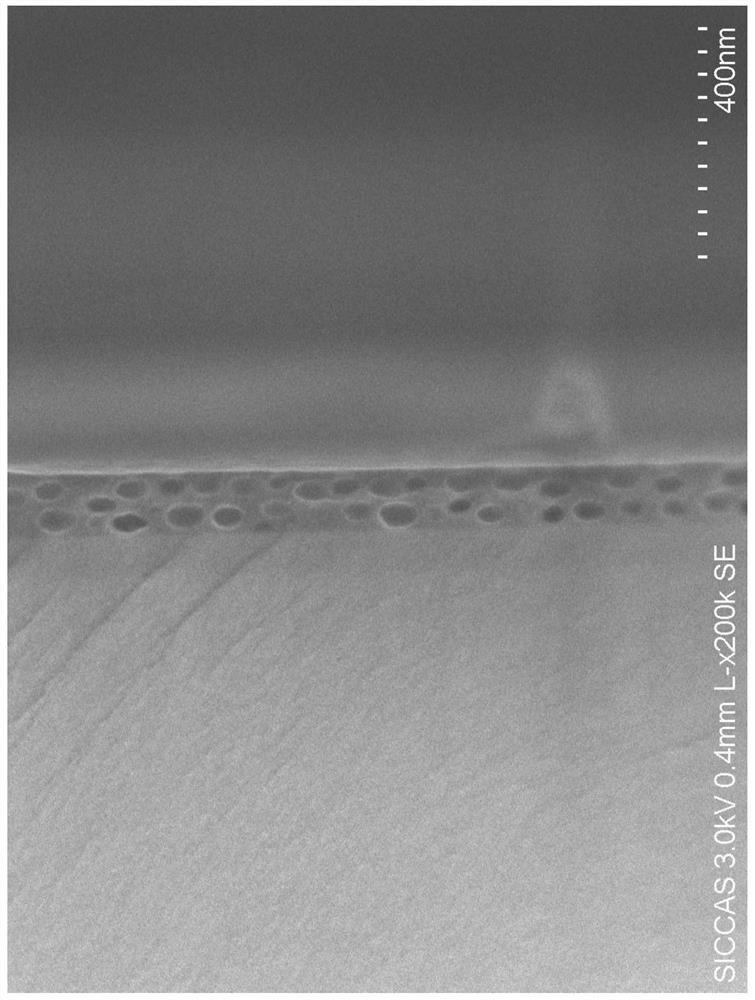

[0092] After cleaning the photovoltaic glass, first coat a layer of bottom coating solution on the surface of the glass to form a bottom coating layer. layer of anti-reflection coating. Anti-reflection, dirt resistance and weather resistance tests were carried out on the coated glass, the results are shown in the table below:

[0093]

[0094] Remarks: Dirt resistance is divided into grades 1-5 based on the light weight of the imprint left on the membrane surface. The higher the grade, the worse the dirt resistance, and ≤3 grades are qualified.

[0095] The test results in the above table show that the double-coated glass obtained by the anti-reflection solution prepared by the method of the present invention has higher light transmittance, excellent dirt resistance and weather resistance; and can significantly improve the light transmittance of long-wave band (infrared) rate, that is, to increase the absorption of ultraviolet and infrared light at the same time, it can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com