Salt-tolerant alkali-resistant aerobic denitrifying bacterium and application thereof

An aerobic denitrification and bacterial technology, applied in the field of environmental microorganisms and water treatment, can solve the problems of denitrification efficiency reduction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

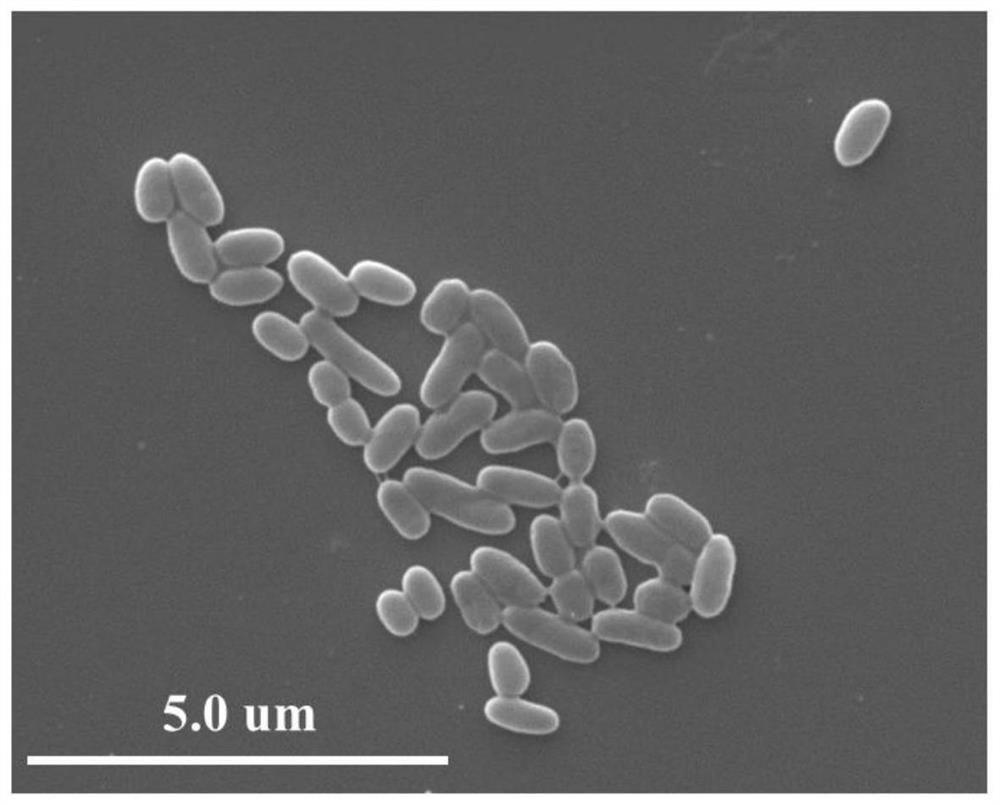

[0024] Screening of strains resistant to salt and alkali and aerobic denitrification.

[0025] Specific steps are as follows:

[0026] 1) Prepare aerobic denitrifying bacteria enrichment medium: yeast extract 0.5g / L, peptone 0.5g / L, sodium chloride 30g / L, glucose 0.5g / L, starch 0.5g / L, sodium pyruvate 0.3 g / L, dipotassium hydrogen phosphate 0.3g / L, magnesium sulfate 0.05g / L, dissolve in deionized water, adjust the pH to 7, and steam sterilize at 121°C for 30min.

[0027] 2) Inoculate 10 mL of high-salt activated excess sludge (Wastewater Treatment Plant of Tianjin Dagu Chemical Industry Co., Ltd.) into a 250 mL Erlenmeyer flask containing 100 mL of the above-mentioned liquid medium, and culture on a shaking table at 30° C. and 140 r / min for 5 days. A total of three generations of culture and enrichment were carried out to obtain a mixed bacterial solution.

[0028] 3) Prepare BTB medium for the isolation of aerobic denitrifying bacteria: potassium nitrate 1g / L, sodium succin...

Embodiment 2

[0034] Denitrification experiment of strains under high salt (salinity: 3%) conditions

[0035] The specific implementation steps are as follows:

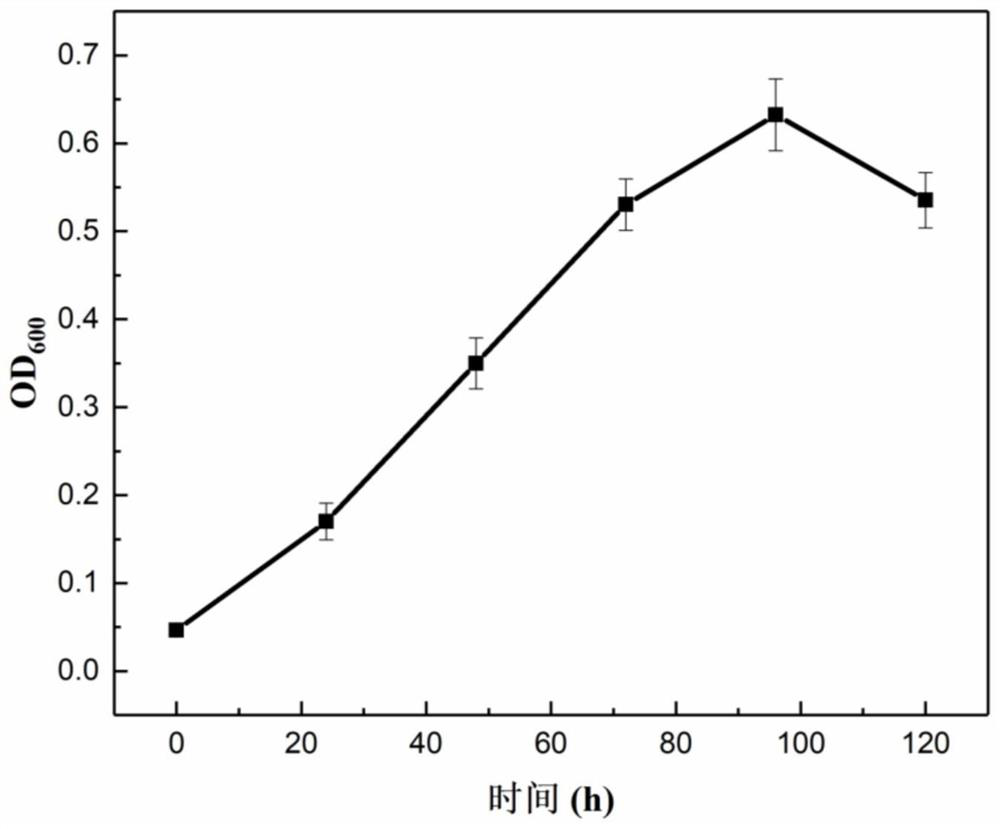

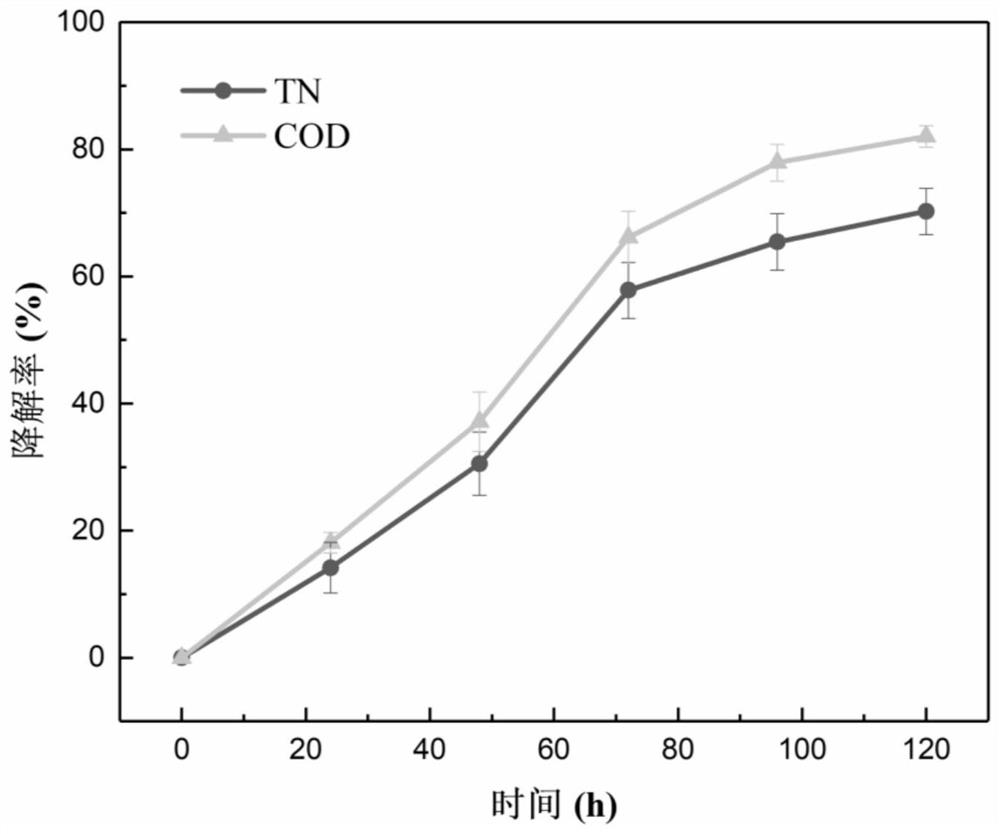

[0036] Inoculate the above-mentioned denitrifying bacterial strain MSD4 into 100mL liquid denitrifying DM medium (potassium nitrate 0.72g / L, sodium succinate 2.8g / L, sodium chloride 30g / L, dipotassium hydrogen phosphate 1g / L, seven Magnesium sulfate water 1g / L) in a 250mL Erlenmeyer flask, placed in a shaker at 30°C and 140r / min for culture, and an uninoculated blank medium was used as a blank control. After inoculation, take a small amount of bacterial liquid according to 0h, 24h, 48h, 72h, 96h and 120h, and a part of the samples are used to determine the optical density of the bacteria (OD 600 ), taking time as the abscissa, OD 600 The growth curve of the denitrifying bacteria is plotted on the ordinate, and the growth cycle of the strain is observed. The rest of the bacterial liquid was centrifuged at 10 000 rpm for 2 min, an...

Embodiment 3

[0041] Denitrification experiments of strains under different salinity conditions

[0042] The specific implementation steps are as follows:

[0043] The strain MSD4 was inoculated in a denitrified DM medium with a salinity (calculated as NaCl) of 3%, and pre-cultured in a shaker at 30°C and 140r / min. After the strain grows to the logarithmic growth phase, take 30mL of the bacterial liquid and insert it into fresh 300mL denitrification DM medium with a salinity (calculated as NaCl) of 0%, 3%, 5%, 7%, 10% and 12%. , the initial pH was set to 7, and the shaking culture was carried out in a shaker at 30°C and 140r / min. The culture medium that was not inoculated with bacterial solution was used as a blank control for experiments under the same conditions. A small amount of bacterial liquid was taken at 0 h and 120 h after inoculation, and a part of it was directly used to measure the optical density (OD) of the bacterial cells. 600 ), the rest was centrifuged at 10 000 rpm for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com