Engineering strain of mannosidase and application of engineering strain

A mannosidase and mannan technology, applied in the field of bioengineering, can solve the problems of high production cost of mannan, and achieve the effects of easy separation and purification, simple operation process and strong protein expression ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

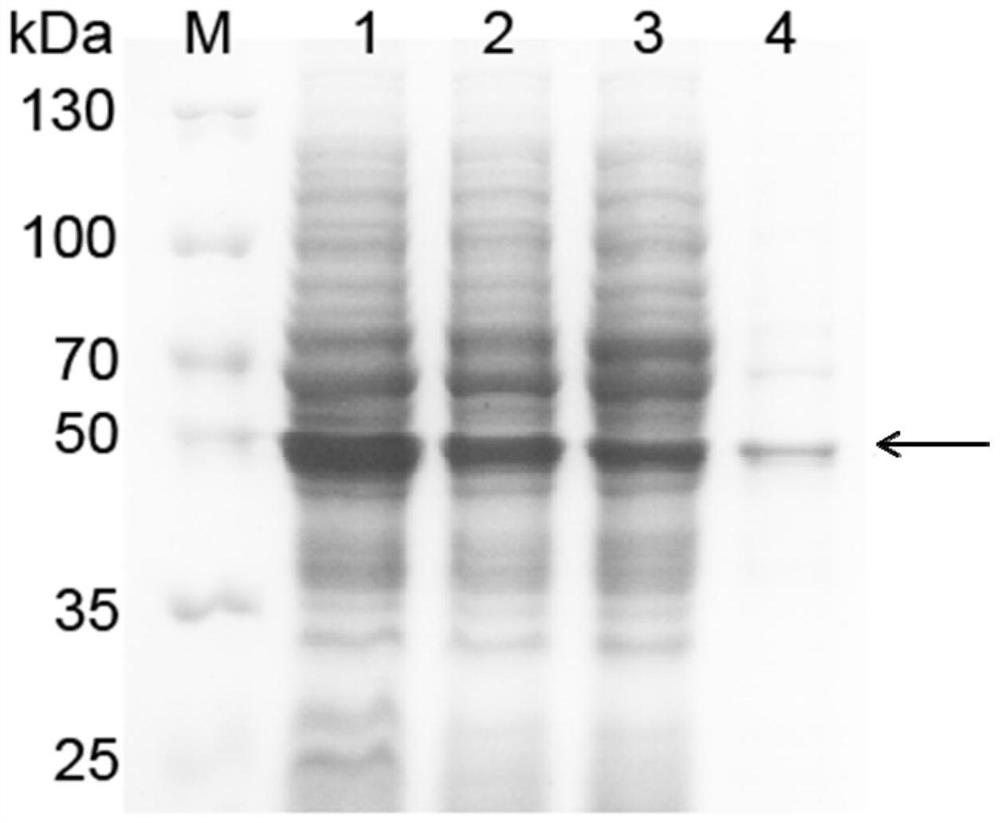

[0038] Example 1: Acquisition of TFMS and expression of recombinant Escherichia coli

[0039] 1. Heterologous expression of TFMS gene

[0040] Using the TFMS gene sequence in Thermobifida fusca as a template, the codon was optimized and synthesized according to the degeneracy of the codon. The TFMS gene (nucleotide sequence shown in SEQ ID NO.2) with a size of 1362bp was introduced, and NdeI and XhoI restriction site, the synthetic product is double-digested with NdeI and XhoI, and the restriction fragment is purified and recovered. Then, the pET21a empty plasmid was double digested with the same enzyme, purified and recovered, ligated with the fragment obtained above, and the ligated product was transformed into E.coliBL21(DE3). Take an appropriate amount of transformation solution and spread it on an LB medium plate, and culture overnight at 37°C. After the colony PCR is correct, pick a single colony and shake the flask to culture and extract the plasmid. After further seq...

Embodiment 2

[0043] The activity characterization of embodiment 2 mannosidase TFMS

[0044] Using konjac glucomannan as the substrate, the enzymatic properties of TFMS were characterized.

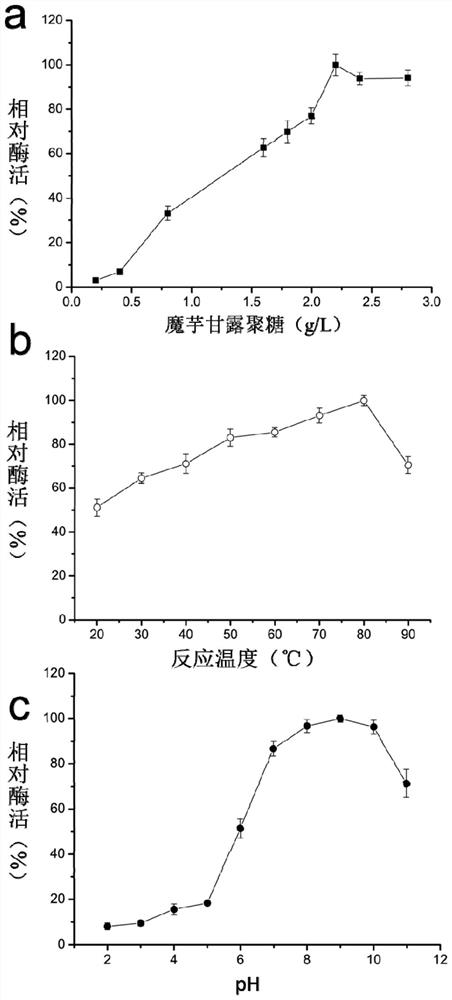

[0045] 1. Weigh 0.2, 0.4, 0.8, 1.6, 1.8, 2.0, 2.2, 2.4, and 2.8 g of konjac flour and dissolve them in 1 L of distilled water to prepare a konjac mannan solution, then add 10 μL of enzyme solution and react at 37°C for 1 hour. Wherein the enzyme liquid is the enzyme powder of TFMS prepared in Example 1 and diluted with deionized water to a concentration of 50 μg / mL. Such as figure 2 As shown in a, as the initial concentration of konjac glucomannan increased from 0.2 g / L to 2.2 g / L, the catalytic activity of TFMS increased rapidly. These results indicated no significant substrate inhibition in fructose biotransformation.

[0046] 2. Determination of the optimum temperature: prepare 2g / L konjac glucomannan as the reaction substrate, add 1mL 2g / L konjac glucomannan to the reaction system, add 200μL of ...

Embodiment 3

[0053] Example 3 Utilizing TFMS Enzyme Solution and Efficient Preparation of Mannan Oligosaccharide Products

[0054] Specific steps are as follows:

[0055] Weigh 0.5g of konjac flour and dissolve it in 50ml of distilled water to prepare konjac mannan solution, then add 5ml of TFMS enzyme solution and react at 37°C for 1h. Wherein the enzyme liquid is the enzyme powder of TFMS prepared in Example 1 and diluted with deionized water to a concentration of 50 μg / mL.

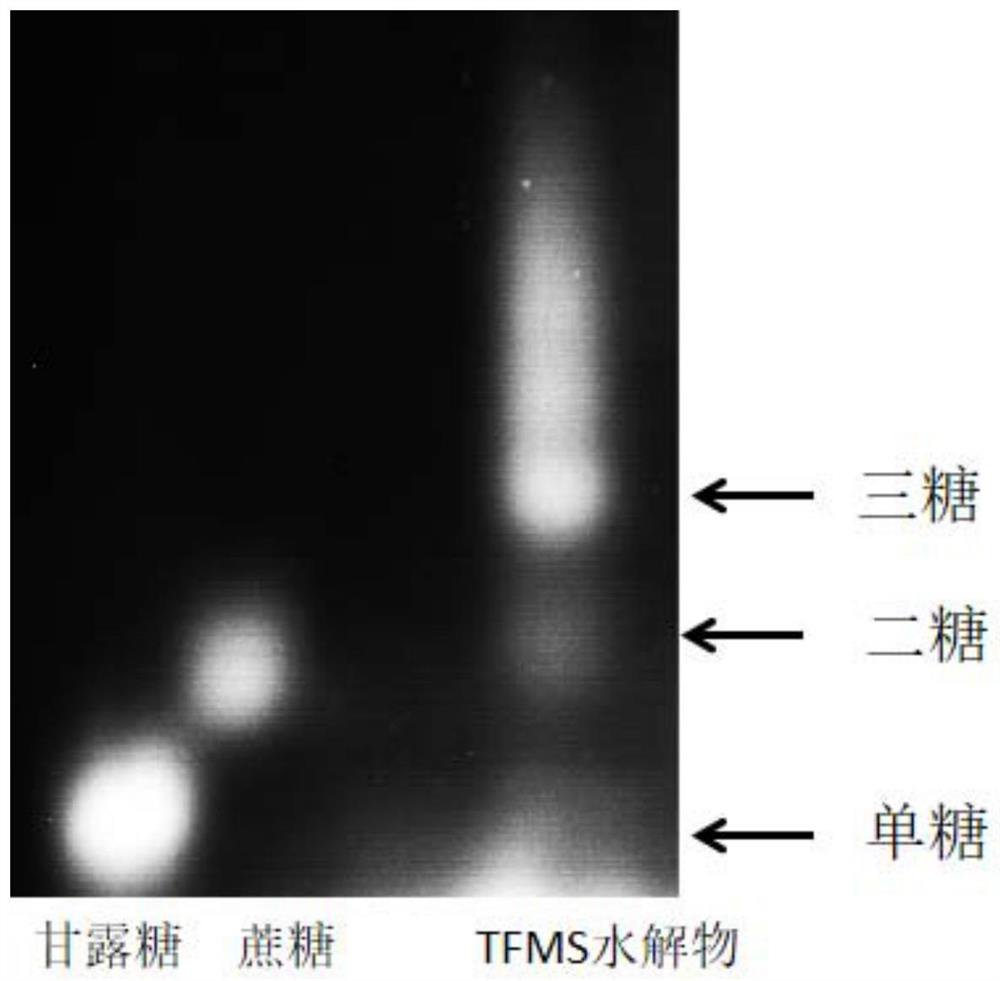

[0056] After the samples were processed, they were subjected to gel fluorescence electrophoresis, and observed under ultraviolet light, the results were as follows: image 3 Shown: With mannose and sucrose as standard controls, the cell disruption solution added with TFMS can hydrolyze konjac mannan into monosaccharides, disaccharides, and trisaccharides, that is, the recombinantly expressed thermophilic mannosidase TFMS can hydrolyze the mannan substrate. The product has achieved effective hydrolysis, and can dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com