Multi-core optical fiber coupler based on three-dimensional waveguide and preparation method

A multi-core optical fiber and coupler technology, which is applied in the field of optical transmission devices, can solve the problems of large waveguide bending loss, high insertion loss of multi-core fiber coupler, and inability to guarantee the uniformity of loss of multi-core fiber coupler, etc., to achieve stable Effects of coupling, optimized optical waveguide arrangement, and low insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

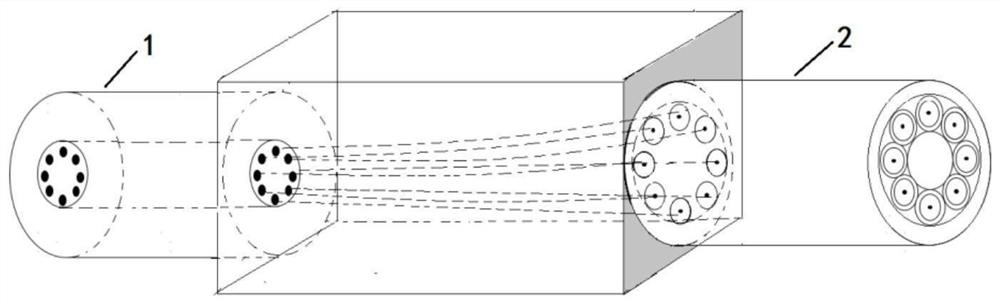

[0071] The preparation method of the multi-core optical fiber coupler provided by the invention comprises the following steps:

[0072] Inserting the multi-core optical fiber with part of the coating layer removed into the cleaned first capillary glass tube 1 to form a multi-core optical fiber head, wherein the core distribution of the multi-core optical fiber is the same as the waveguide arrangement shape at the input end of the three-dimensional waveguide chip;

[0073] Insert the single-mode optical fiber bundle from which part of the coating has been removed into the cleaned second capillary glass tube 2 to form a single-mode optical fiber bundle head, wherein the core distribution of the single-mode optical fiber bundle is consistent with the waveguide arrangement shape at the output end of the three-dimensional waveguide chip same;

[0074] The multi-core optical fiber head is coupled with the input end of the three-dimensional waveguide chip; the single-mode core fiber ...

Embodiment 1

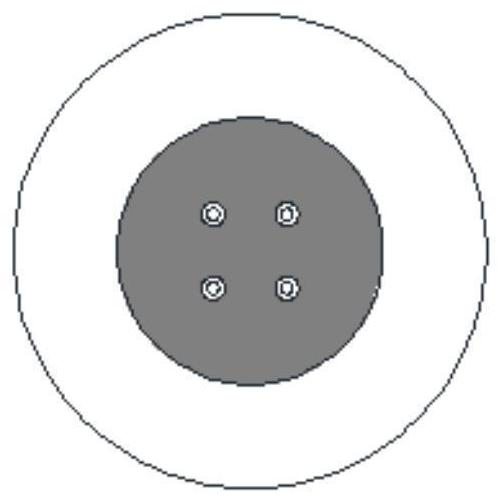

[0076] Example 1: Preparation of a four-core fiber coupler based on a three-dimensional waveguide chip

[0077](1) Preparation of multi-core optical fiber head: strip off the coating layer at the front end of the four-core optical fiber, and clean the multi-core optical fiber with a dust-free paper dipped in absolute ethanol. The front end of the multi-core optical fiber includes a core layer and a cladding layer. About 30mm, the rear end part is a complete optical fiber including core layer, cladding and coating layer, the length of the rear end is about 1.5m; the first capillary glass tube 1 is a high borosilicate glass capillary tube with a circular through hole in the axial center , with a length of about 20mm, one end of which can be made into a bell mouth to facilitate the insertion of optical fibers without damaging the coating layer of the multi-core optical fiber. The inner diameter of the circular hole is slightly larger than the outer diameter of the multi-core optic...

Embodiment 2

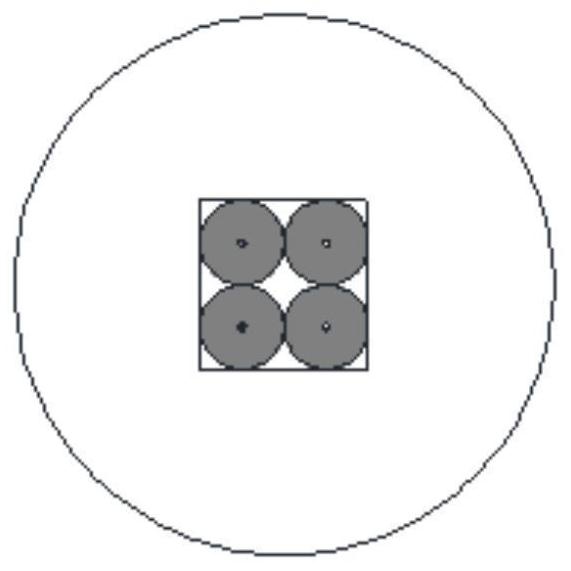

[0091] Embodiment 2 The preparation of annular eight-core coupler

[0092] The preparation principle of the ring eight-core coupler is the same as the four-core fiber coupler, the difference lies in (1) the preparation of the multi-core fiber head; (2) the preparation of the single-mode fiber bundle head; (3) the arrangement of the optical waveguide of the three-dimensional waveguide chip.

[0093] (1) Preparation of multi-core optical fiber head: strip off the coating layer on the front end of the eight-core optical fiber, and clean the multi-core optical fiber with a dust-free paper dipped in absolute ethanol. About 30mm, the rear end part is a complete optical fiber including core layer, cladding and coating layer, the length of the rear end is about 1.5m; the first capillary glass tube 1 is a high borosilicate glass capillary tube with a circular through hole in the axial center , with a length of about 20mm, one end of which can be made into a bell mouth to facilitate the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com