Preparation method of high-flux self-supporting MOF glass gas separation membrane for difficult-to-separate system

A gas separation membrane, self-supporting technology, applied in the field of membrane separation, which can solve the problems of low output and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a self-supporting MOF glass gas separation membrane with high selectivity and high flux for difficult separation systems, characterized in that it comprises the following steps:

[0032] (1) mix the mixed metal sources and the ligands in different molar ratios uniformly according to a certain molar ratio, use a planetary ball mill to carry out ball milling, carry out suction filtration to the obtained product, wash with methanol, and obtain ZIF-62 particles;

[0033] (2) Calcining the powder obtained in step (1) by using a tube furnace to obtain vitrified ZIF-62.

[0034] (3) The traditional hydrothermal method was used to prepare ZIF-62 powder for comparison with the ball milling method.

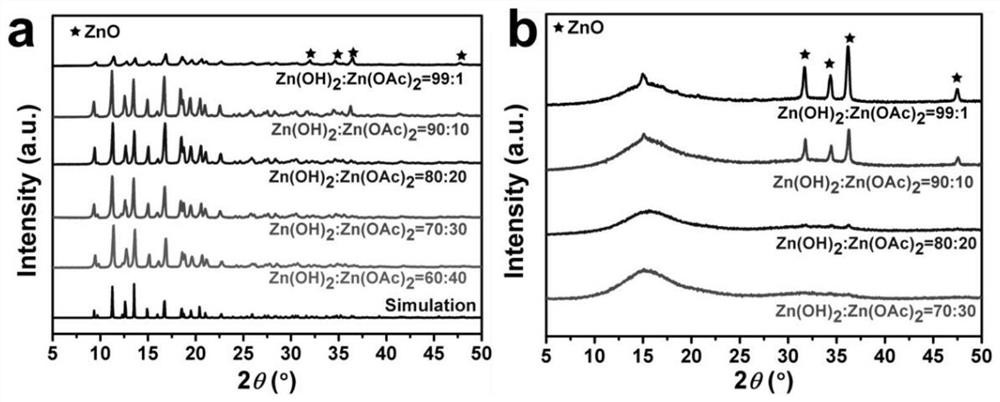

[0035] Table 1 shows that the characteristic description that obtains product when metal salt is different mol ratio, can find out that ZIF-62 without impurity can be obtained when the mol ratio of zinc hydroxide and zinc acetate is 70:30, and this is because z...

Embodiment 2

[0044] A method for preparing a self-supporting MOF glass gas separation membrane with high selectivity and high flux for difficult separation systems, characterized in that it comprises the following steps:

[0045](1) get 300 mg of ZIF-62 powder and adopt a mechanical tablet press to prepare discs with a certain diameter and thickness;

[0046] (2) Calcining the disc obtained in step (1) by using a tube furnace to obtain a self-supporting ZIF-62 glass film.

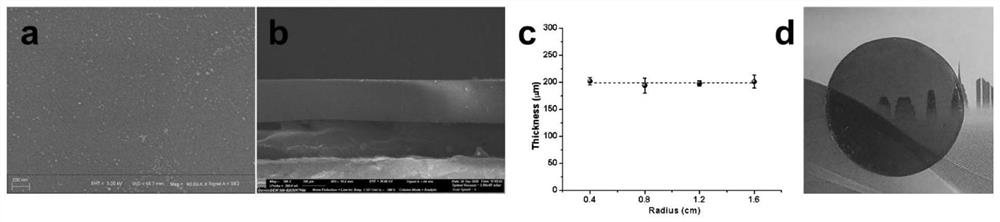

[0047] figure 2 It shows that the membrane surface of the self-supporting vitrified MOF membrane is very dense without defects (A); the cross-section of the membrane is also very dense (B); the thickness of the membrane cross-section is uniform (C). The light transmittance of the glass film is good, in line with the optical properties of glass (D).

Embodiment 3

[0049] A method for preparing a self-supporting MOF glass gas separation membrane with high selectivity and high flux for difficult separation systems, characterized in that it comprises the following steps:

[0050] (1) get the ZIF-62 powder of 400 milligrams and adopt mechanical tabletting machine, be prepared into the disc of certain diameter, thickness;

[0051] (2) Calcining the disc obtained in step (1) by using a tube furnace to obtain a self-supporting ZIF-62 glass film.

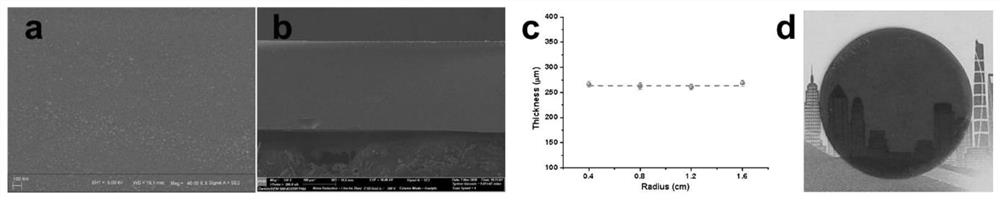

[0052] image 3 It shows that the membrane surface of the self-supporting vitrified MOF membrane is very dense without defects (A); the cross-section of the membrane is also very dense (B); the thickness of the membrane cross-section is uniform (C). The light transmittance of the glass film is good, in line with the optical properties of glass (D).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com