Application of amphiphilic block copolymer and preparation method of degradable photonic crystal microspheres

A technology of photonic crystal microspheres and amphiphilic blocks, which is applied in the preparation of degradable photonic crystal microspheres and the application field of amphiphilic block copolymers, and can solve the problems of harsh preparation conditions, complicated operations, and many steps , to achieve the effect of simple preparation process, high safety performance and single color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

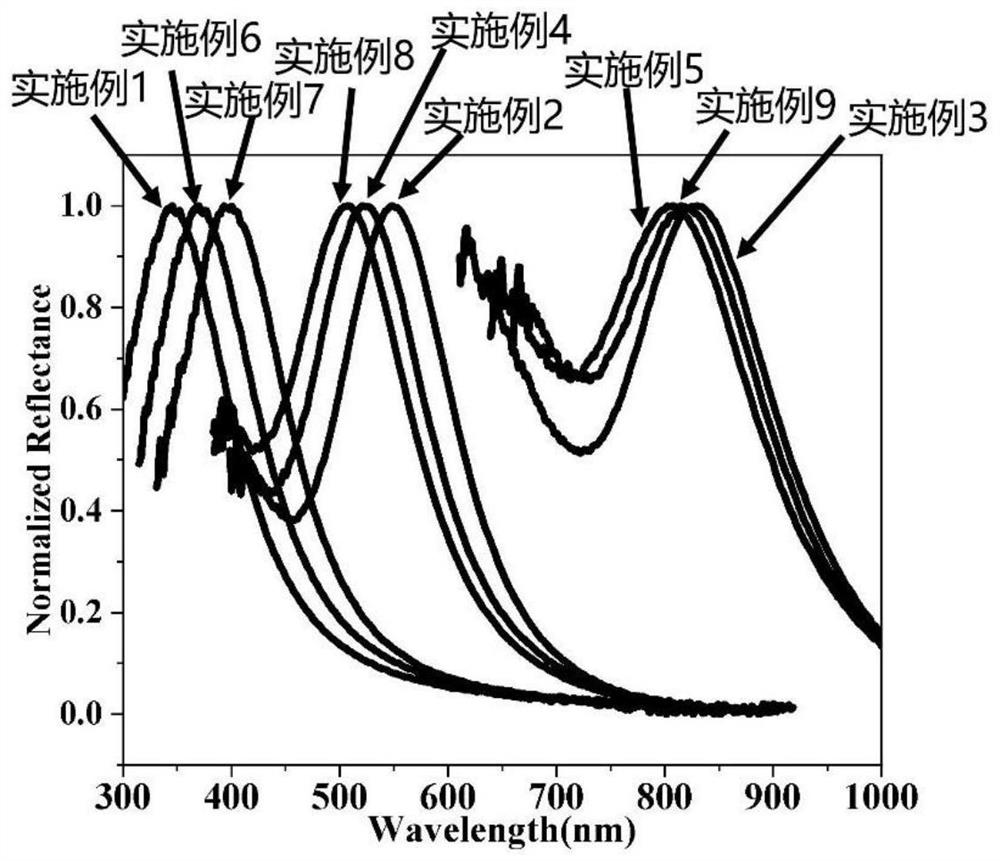

Embodiment 1

[0077] (1) Preparation of amphiphilic block copolymer brush PCL-b-PEO

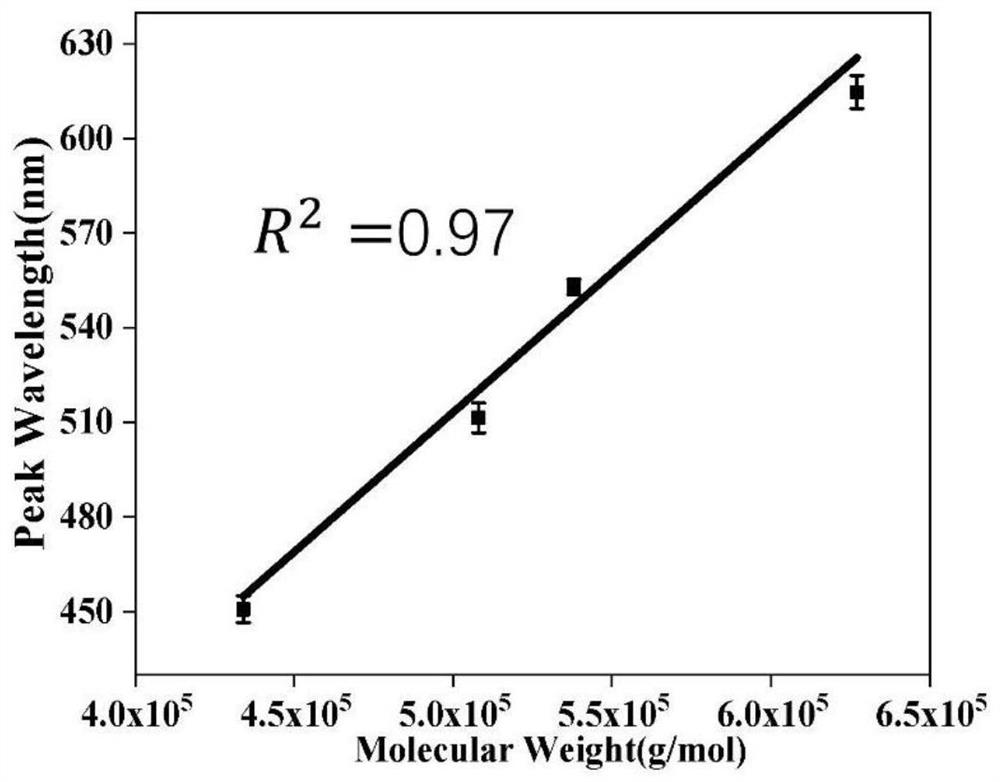

[0078] Add caprolactone (ε-CL) and benzyl alcohol (BnOH) into toluene to dissolve, then add phosphazene base (P4-t-Bu) and react at room temperature for 40min to obtain a molecular weight of 1×10 4 g / mol polycaprolactone Bn-PCL terminated with a benzene ring; wherein, the molar ratio of benzyl alcohol to caprolactone is 1:9, and the molar ratio of catalyst to benzyl alcohol is 1:100.

[0079] The obtained Bn-PCL was esterified with norbornene (NB) at room temperature for 48 h to obtain norbornene-terminated polycaprolactone NB-PCL, and the catalyst for the esterification reaction was 4-dimethylaminopyridine (DMAP ), the dehydrating agent is dicyclohexylcarbodiimide (DCC), followed by precipitation with ice methanol for 3 times, and drying in a vacuum oven at 35°C for 12h;

[0080] The molecular weight is 8×10 4 g / mol polyethylene glycol monomethyl ether (PEO-CH 3 ) and norbornene acid (NB) were esterifi...

Embodiment 2

[0086] (1) Preparation of amphiphilic block copolymer brush PCL-b-PEO

[0087] Add caprolactone (ε-CL) and benzyl alcohol (BnOH) into toluene to dissolve, then add phosphazene base (P4-t-Bu) and react at room temperature for 40min to obtain a molecular weight of 8×10 4 g / mol polycaprolactone Bn-PCL terminated with a benzene ring; wherein, the molar ratio of benzyl alcohol to caprolactone is 1:10, and the molar ratio of catalyst to benzyl alcohol is 1:100.

[0088] The obtained Bn-PCL was esterified with norbornene (NB) at room temperature for 48 h to obtain norbornene-terminated polycaprolactone NB-PCL, and the catalyst for the esterification reaction was 4-dimethylaminopyridine (DMAP ), the dehydrating agent is dicyclohexylcarbodiimide (DCC), followed by precipitation with ice methanol for 3 times, and drying in a vacuum oven at 35°C for 12h;

[0089] The molecular weight is 7×10 4 g / mol polyethylene glycol monomethyl ether (PEO-CH 3 ) and norbornene acid (NB) were esterifie...

Embodiment 3

[0095] (1) Preparation of amphiphilic block copolymer brush PCL-b-PEO

[0096] Add caprolactone (ε-CL) and benzyl alcohol (BnOH) into toluene to dissolve, then add phosphazene base (P4-t-Bu) and react at room temperature for 40min to obtain a molecular weight of 5×10 4 g / mol polycaprolactone Bn-PCL terminated by a terminal benzene ring; wherein, the molar ratio of benzyl alcohol to caprolactone is 1:70, and the molar ratio of catalyst to benzyl alcohol is 1:100.

[0097] The obtained Bn-PCL was esterified with norbornene (NB) at room temperature for 48 h to obtain norbornene-terminated polycaprolactone NB-PCL, and the catalyst for the esterification reaction was 4-dimethylaminopyridine (DMAP ), the dehydrating agent is dicyclohexylcarbodiimide (DCC), followed by precipitation with ice methanol for 3 times, and drying in a vacuum oven at 35°C for 12h;

[0098] The molecular weight is 1×10 4 g / mol polyethylene glycol monomethyl ether (PEO-CH 3 ) and norbornene acid (NB) were ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com