Medical nickel-titanium alloy material with thermo-sensitive hydrogel coating as well as preparation method and application of medical nickel-titanium alloy material

A temperature-sensitive hydrogel and nickel-titanium alloy technology, which is applied in coatings, pharmaceutical formulations, medical science, etc., can solve the problems of poor mechanical properties and inability to use medical implant materials, so as to improve the binding force and eliminate the safety Hidden dangers, the effect of improving binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

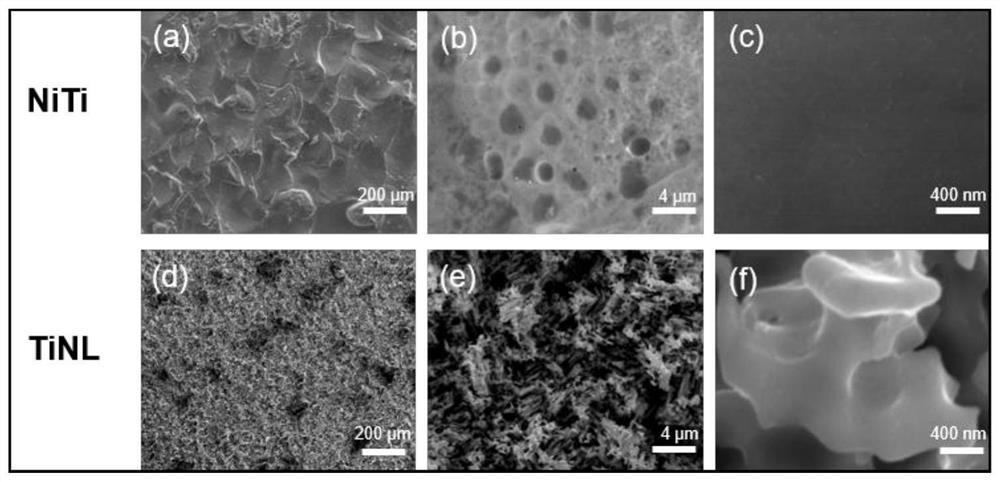

[0047] (1) Materials Pretreatment: Medical Nitinol (nickel-titanium atomic ratio of 1: 1) by the wire cutting into the material The sheet-like sample, pickling, pickling, acid-wash a mass fraction of 40% HF, 60% of the mass fraction of HNO 3 Ho 2 Mixed O, pickling time is 10min; HF, HNO 3 Ho 2 O volume ratio of 1: 5:35 washing and drying, and washed with deionized water, ultrasonic cleaning 10min, after drying at room temperature standby abbreviated as "NiTi".

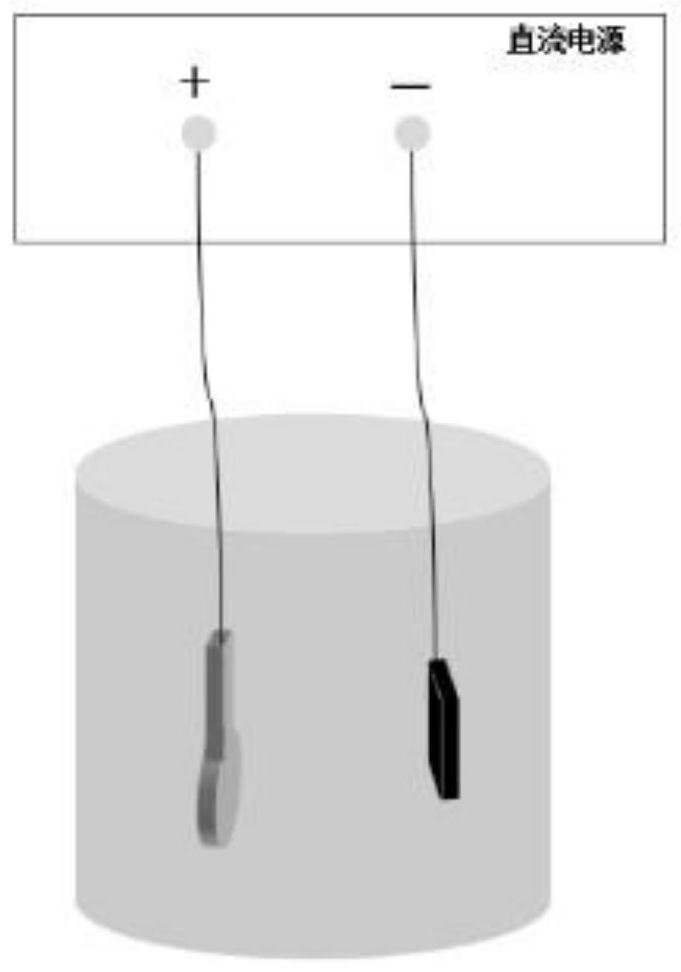

[0048] (2) Anodization: a concentration of 1mol / L of HNO 3 As an electrolytic solution, a step of processing a nickel-titanium alloy well as an anode, a graphite sheet as the cathode, two electrode distance is set to 40mm, oxidation 2min, after the reaction taken nitinol washed several times with deionized water at a voltage of 6V after 5min ultrasound and deionized water, drying stand, named "TiNL".

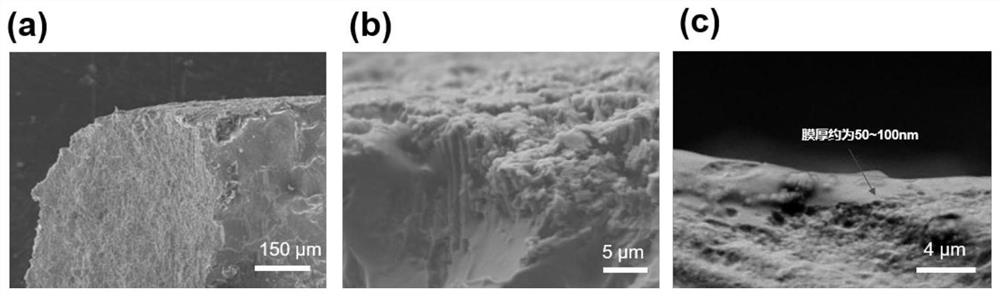

[0049] (3) thermal oxidation: the step (2) nickel-titanium alloy treated at a rate of temperature increase 5 ℃ / min ...

Embodiment 2

[0054] (1) Materials Pretreatment: Medical Nitinol (nickel-titanium atomic ratio of 1: 1) by the wire cutting into the material The sheet-like sample, pickling, pickling, acid-wash a mass fraction of 40% HF, 60% of the mass fraction of HNO 3 Ho 2 Mixed O, pickling time 5min; HF, HNO 3 Ho 2 O volume ratio of 5:10:35. Washing and drying, and washed with deionized water, ultrasonic cleaning 10min, after drying at room temperature for standby.

[0055] (2) Anodization: a concentration of 2.5mol / L of HNO 3 As an electrolytic solution, a step of processing a nickel-titanium alloy well as an anode, a graphite sheet as the cathode, two electrode distance is set to 40mm, oxidation 90min, after the reaction taken nitinol washed several times with deionized water at a voltage of 2V after 5min ultrasound and deionized water, drying stand.

[0056] (3) thermal oxidation: the step (2) nickel-titanium alloy treated at a rate of temperature increase 5 ℃ / min raised to 350 ℃, and incubated 3...

Embodiment 3

[0061] (1) Materials Pretreatment: Medical Nitinol (nickel-titanium atomic ratio of 1: 1) by the wire cutting into the material The sheet-like sample, pickling, pickling, acid-wash a mass fraction of 40% HF, 60% of the mass fraction of HNO 3 Ho 2 Mixed O, the pickling time was 5min; HF, HNO 3 Ho 2 O volume ratio of 3: 5: 60 Washing and drying, and washed with deionized water, ultrasonic cleaning 10min, after drying at room temperature for standby.

[0062] (2) Anodization: a concentration of 2.5mol / L of HNO 3 As an electrolytic solution, a step of processing a nickel-titanium alloy well as an anode, a graphite sheet as the cathode, two electrode distance is set to 40mm, oxidation 20min, after the reaction taken nitinol washed several times with deionized water at 5V after 5min ultrasound and deionized water, drying stand.

[0063](3) thermal oxidation: nitinol step (2) is treated at a rate of temperature rise 8 ℃ / min raised to 650 ℃, and incubated 2h. The sample was then so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com