Synthesis process and effect of bifida ferment lysate and carnosine composition

A technology of bifid yeast and fermentation products, which is applied in the field of synthesis of bifid yeast fermentation product lysate and carnosine composition, which can solve the problems of reduced antioxidant activity, free radical scavenging rate attenuation, increased production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

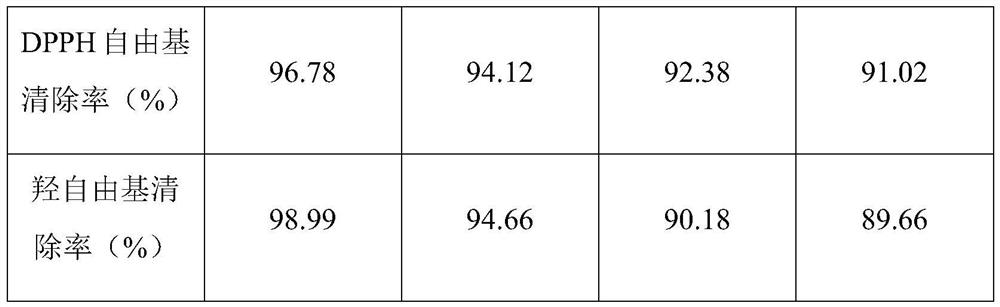

Embodiment 1

[0029] A two-lobed yeast fermentation product synthesis and lysate carnosine composition, the two-lobed yeast fermentation product synthesis and lysate carnosine composition includes the following production steps:

[0030] (1) Acetobacter xylinum and the yeast two-lobed mass ratio of 1: 2 were mixed in 60 times the mass of the yeast two-lobed liquid medium, mixed at a temperature under 36 ℃ culture broth to a pH of less than 4.0, the rotational speed of 3000r / min, under conditions centrifuged 10min, and filtered to give a mixed bacterial cellulose;

[0031] (2) Step (1) mixing the resultant bacterial cellulose with sterile ultrapure water by mass was mixed 1:60 redissolved in a beaker, and mixed bacterial cellulose was added 0.15 times the mass of lysozyme beaker, at a temperature after 15min the reaction was stirred at 35 ℃, the conditions of speed of 260r min / , mixing again the beaker was added 0.3 times the mass of the bacterial cellulose sodium alginate, thermal cracking a...

Embodiment 2

[0038] A two-lobed yeast fermentation product synthesis and lysate carnosine composition, the two-lobed yeast fermentation product synthesis and lysate carnosine composition includes the following production steps:

[0039] (1) The yeast two-lobed mass ratio of 1: 2 were mixed in 60 times the mass of the yeast two-lobed liquid medium, mixed at a temperature under 36 ℃ culture broth to a pH of less than 4.0, the rotational speed of 3000r after the conditions / min centrifugation 10min, filtered to obtain two-lobed yeast fermentation product;

[0040] (2) Step (1) Yeast fermentation product obtained bifid sterile ultrapure water by mass was mixed 1:60 redissolved in a beaker, and mixed bacterial cellulose was added 0.15 times the mass of the beaker lysozyme, in temperature 35 ℃, under stirring speed of 260r / min after the reaction 15min, again mixing sodium alginate beaker 0.3 times the mass of the bacterial cellulose, thermal cracking after 18min, and filtered to give the modified...

Embodiment 3

[0047] A two-lobed yeast fermentation product synthesis and lysate carnosine composition, the two-lobed yeast fermentation product synthesis and lysate carnosine composition includes the following production steps:

[0048] (1) Acetobacter xylinum and the yeast two-lobed mass ratio of 1: 2 were mixed in 60 times the mass of the yeast two-lobed liquid medium, mixed at a temperature under 36 ℃ culture broth to a pH of less than 4.0, the rotational speed of 3000r / min, under conditions centrifuged 10min, and filtered to give a mixed bacterial cellulose;

[0049] (2) Step (1) mixing the resultant bacterial cellulose with sterile ultrapure water by mass was mixed 1:60 redissolved in a beaker, and mixed bacterial cellulose was added 0.15 times the mass of lysozyme beaker, at a temperature after 15min the reaction was stirred at 35 ℃, the conditions of speed of 260r min / , mixing again the beaker was added 0.3 times the mass of the bacterial cellulose sodium alginate, thermal cracking a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com