Mesoporous manganese oxide nano-enzyme with spherical yolk-eggshell structure, and preparation method and application thereof

A manganese oxide, nano-enzyme technology, applied in the field of nano-materials, can solve problems such as poor catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Concrete preparation method comprises the following steps:

[0043] (1) Dissolve Pluronic F127 in alkaline ethanol / water solution, stir at room temperature until Pluronic F127 is completely dissolved, add tannic acid and formaldehyde solution, and stir for 24 hours to obtain a tannic acid oligomer precursor; Add Mn to the above solution 2+ Ion aqueous solution, after stirring for 12 hours, put the reaction system in a hydrothermal kettle at 100°C for 12 hours, and after the completion of the hydrothermal treatment, collect by centrifugation and dry to obtain manganese-tannic acid-formaldehyde polymer balls;

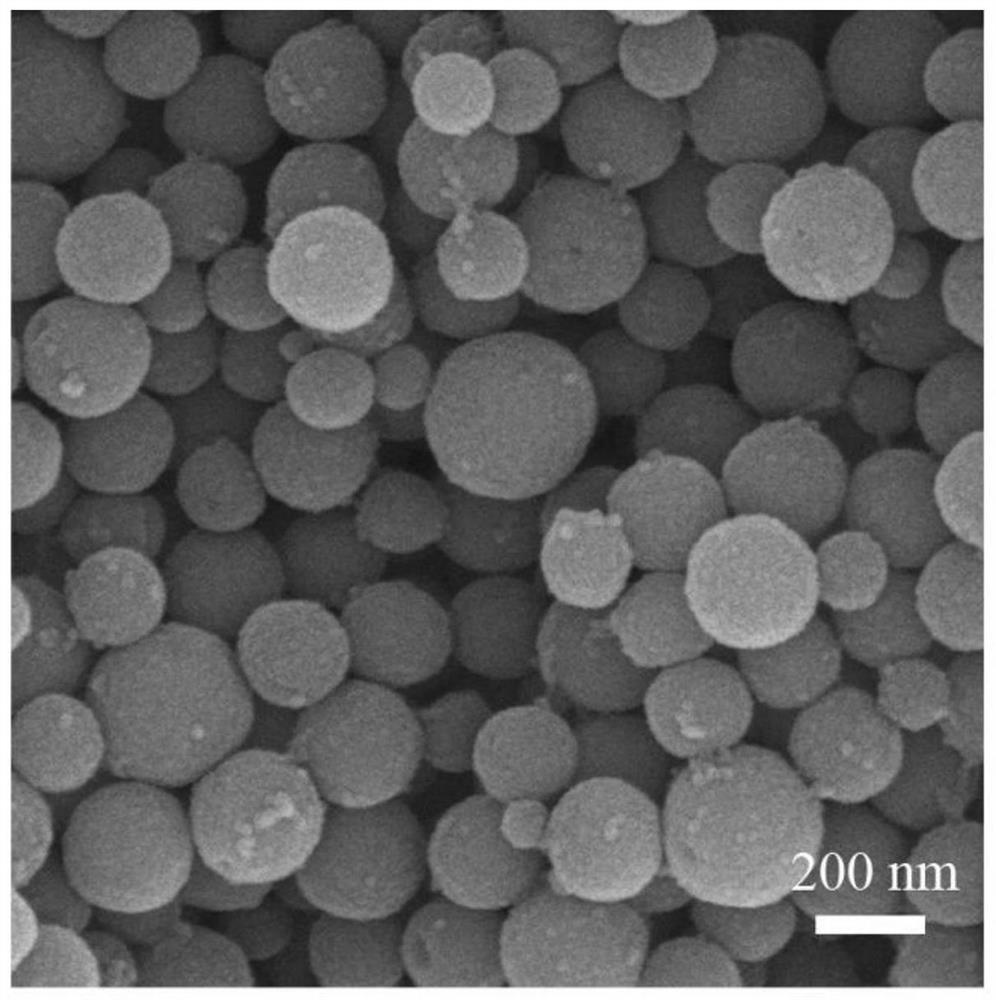

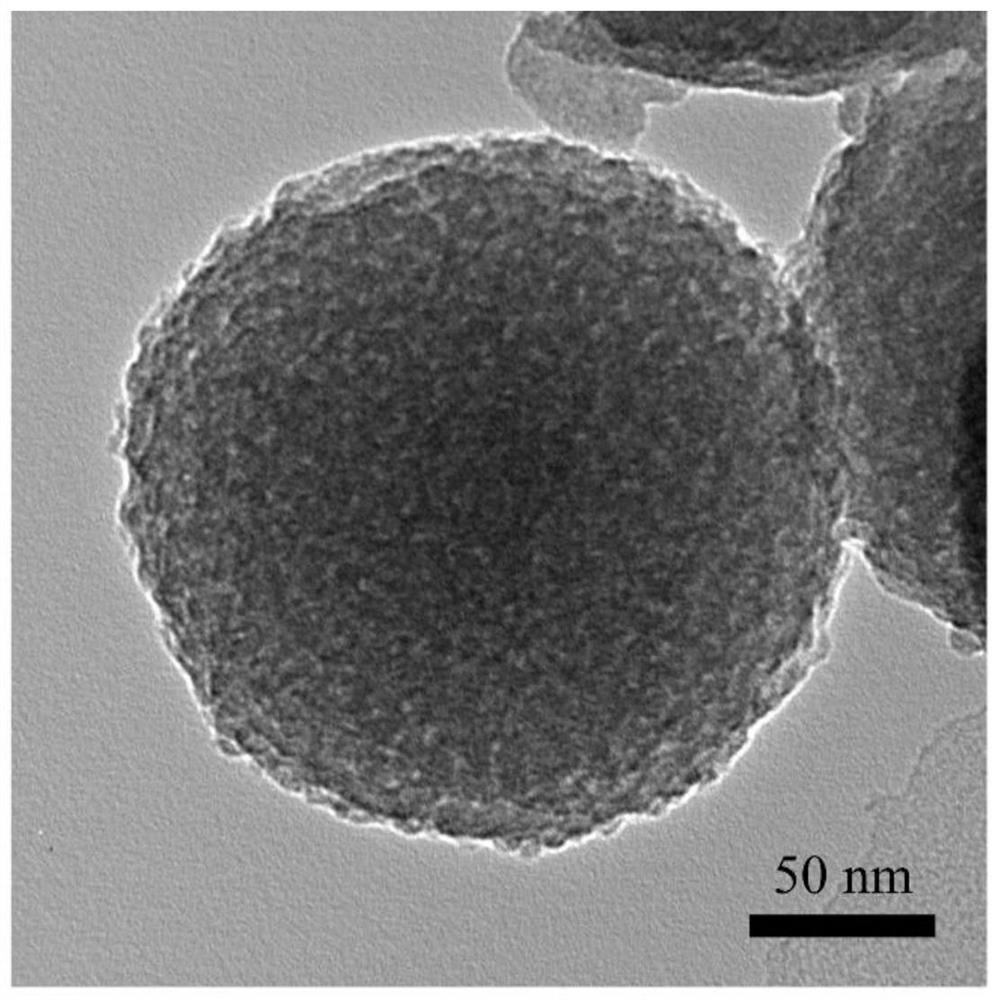

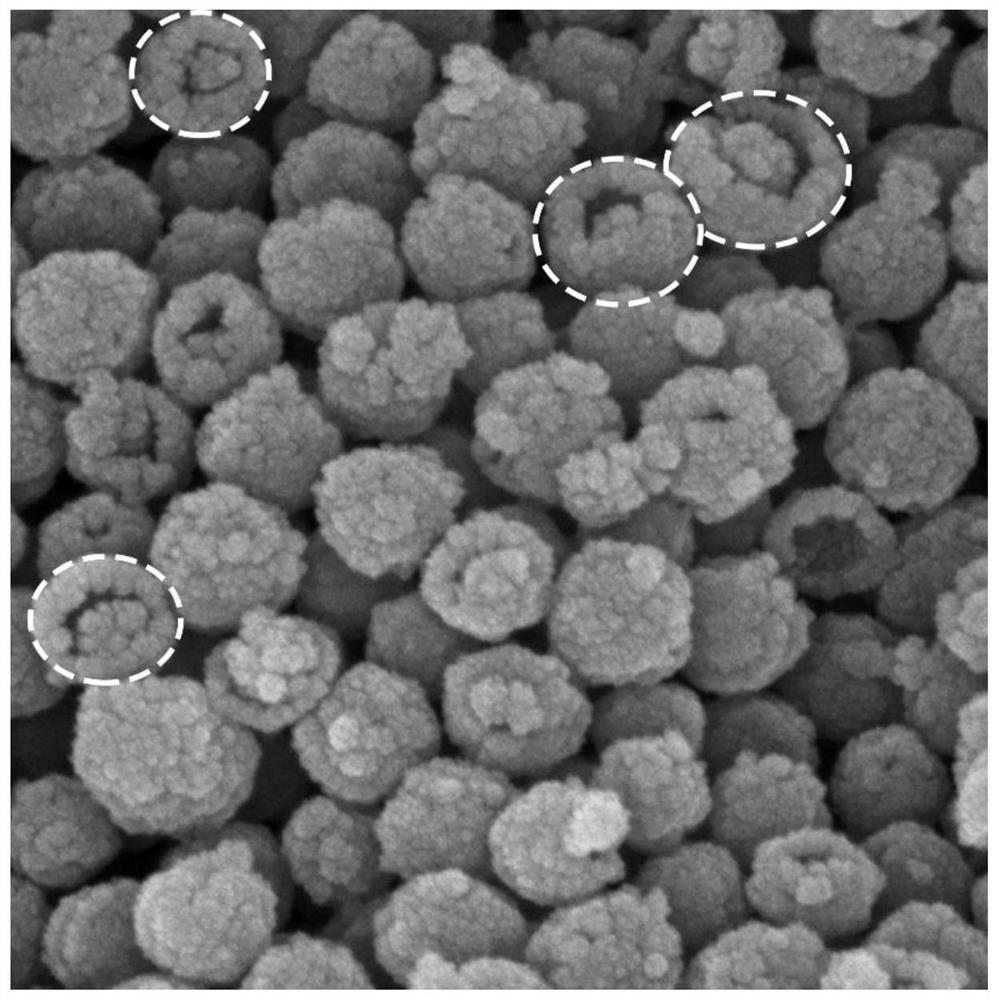

[0044] (2) Roast the above-mentioned manganese-tannic acid-formaldehyde polymer balls in an air atmosphere, the roasting temperature is 300°C, the roasting time is 3h, and the heating rate is 2°C / min to obtain spherical egg yolk-eggshell structure mesoporous Manganese oxide nanoenzyme material.

[0045] The oxidase-like catalytic application of the spherical egg ...

Embodiment 1

[0048] Synthesis of spherical egg yolk-eggshell structure mesoporous manganese oxide nanozyme material:

[0049] (1) Accurately weigh 0.30g of Pluronic F127 in 45.4mL of alkaline ethanol / water solution, wherein the ratio of water, ethanol and ammonia water (2.5%) is 34mL: 8mL: 3.4mL, after Pluronic F127 is completely dissolved , to obtain a clear and transparent solution. Accurately weigh 0.20g of tannic acid and 8mL of pure water to prepare a 0.025g / mL aqueous solution of tannic acid, add it to the above solution, then add 3.8mL of formaldehyde solution (3.7wt%), stir fully for 24h, and obtain a brown Opaque solution. Accurately weigh 0.06gMnSO 4 ·H 2 O in 2mL of pure water to make 0.03g / mL of MnSO 4 Add the aqueous solution to the above solution, stir for 12 hours, transfer the obtained brown solution to a 100mL hydrothermal kettle, and heat it in an oven at 100°C for 12 hours. Acid-formaldehyde polymer ball powder.

[0050] (2) Place the above-mentioned manganese-tann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com