Preparation method of metal nanosheet

A metal nanometer and metal film technology, applied in nanotechnology, metal material coating process, ion implantation plating, etc., can solve the problems of large specific surface area of metal nanosheets, long preparation period, and complicated construction steps of metal nanosheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of silver nanosheets, comprising the following steps:

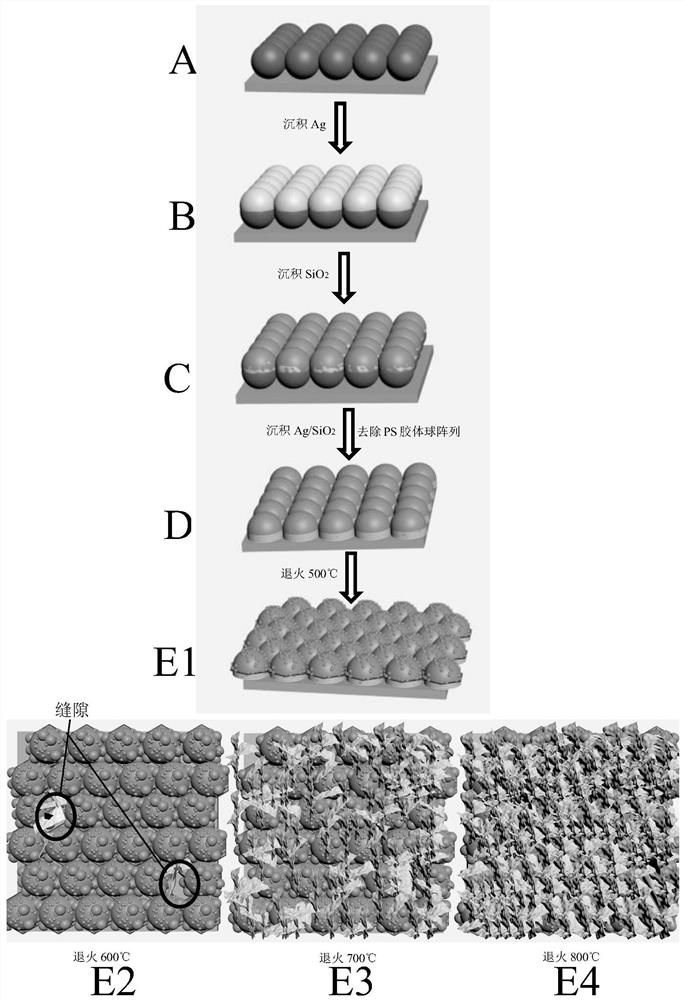

[0033] (A) Utilize the self-assembly method to self-assemble a densely packed PS colloidal ball array template with a diameter of 200 nm on a silicon substrate with a hydrophilic surface (such as figure 1 shown in A);

[0034] (B) after the Ag film with a thickness of 30nm is sputtered on the surface of the PS colloidal sphere array template obtained in step (A), an Ag nanocap array (such as figure 1 as shown in B);

[0035] (C) Continue sputtering a layer of SiO with a thickness of 5 nm in step (B) 2 film, repeating steps (B) and (C) 3 times to obtain nanopillars [Ag / SiO 2 ]n (n=4) multilayer film structure (such as figure 1 C shown);

[0036] (D) For the nanocolumns [Ag / SiO obtained in step (C) 2 ]n (n=4) multilayer film structure Remove the PS colloidal ball array with tetrahydrofuran solution, and wash repeatedly with alcohol or deionized water (such as figure 1 as shown in D);

[0...

Embodiment 2

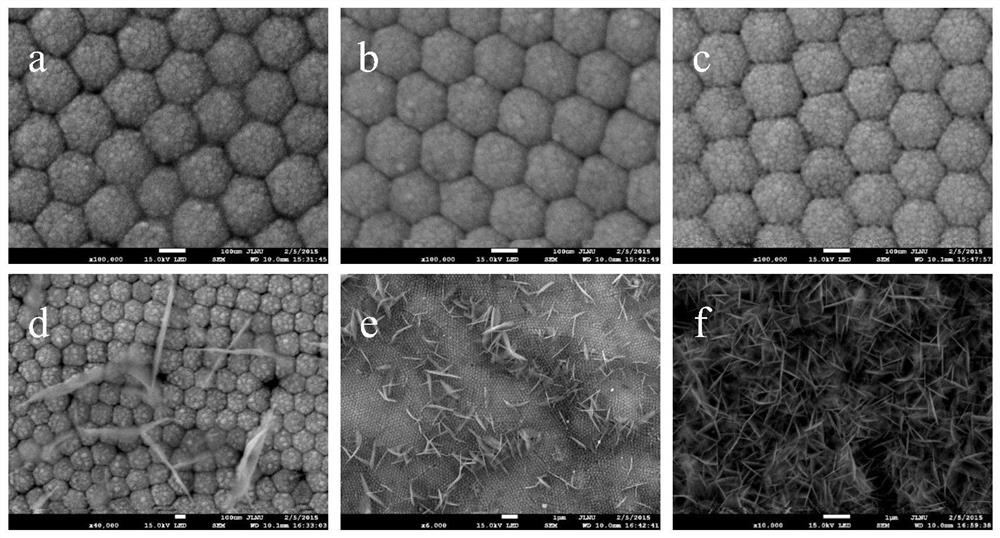

[0039] A method for preparing silver nanosheets. The difference from Example 1 is that the annealing temperature of step (E) in this example is 300° C., and the structure surface does not change substantially, such as figure 2 -a shown.

Embodiment 3

[0041] A preparation method of silver nanosheets, different from Example 1, the annealing temperature of step (E) in this example is 400°C, and the surface of the structure has the phenomenon of grain growth, such as figure 2 -b shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com