A kind of cellulose-based profile and processing technology

A cellulose and hemicellulose technology, used in wood processing appliances, pretreatment of molding materials, manufacturing tools, etc., can solve the problems of low binder strength, difficult mixing of wood-plastic materials, affecting strength, etc., and achieve bending stress. Large, reduce production cost, improve strength and toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

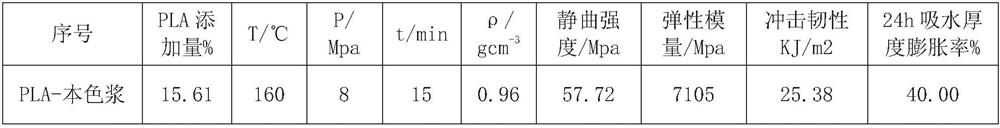

Embodiment 1

[0051] 1. Cook bamboo slices with 13% NaOH solution at 75°C for 10-12 hours, and then rub and refine the pulp to obtain a bamboo color paste with a moisture content of 60% and a pH of 9-10, acidify to a pH of 2-3, and clean it with water. Washed cleanly, screened the pulp, and decomposed by a fiber defibrillator to prepare a pulp with a pulp concentration of 1% for use. The mass content of cellulose (containing hemicellulose) in the bamboo pulp (on a dry weight basis) after acidification was measured to be 58.98%, and the content of acid-insoluble wood was 23.96%.

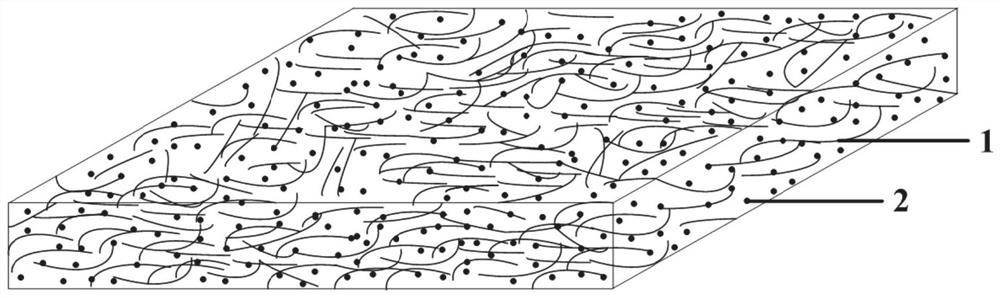

[0052] 2. Add PVC pellets or PLA pellets with a particle size of less than 300 meshes in proportion and mix them evenly. After aging and pre-pressing for 20 minutes, a pulp skeleton substrate with a thickness of 15±1mm is obtained. The schematic diagram of the three-dimensional structure of the pulp skeleton substrate is shown in the appendix figure 1 .

[0053] 3. The pulp skeleton base material is hot-pressed, ...

Embodiment 2

[0062] 1. The pulping method is the same as the step 1 of the above-mentioned embodiment 1.

[0063] 2. Add ultrafine CaCO in proportion 4 or / and CaSO 4 The powder is mixed evenly, aged, pre-pressed for 20 minutes, and dried at <100 °C.

[0064] 3. Add PVA solution in proportion, and dry at <100℃.

[0065] 4. The pulp skeleton base material is hot-pressed, pressure-maintained and cooled to obtain the product. The specific properties are shown in Table 3.

[0066] Table 3 Preparation conditions and product properties of PVA-natural paste

[0067]

[0068] The results in Table 3 show that: the PVA-fiber-based composite material with an addition amount of less than 15%, without adding nano-calcium material, the mass ratio of the sum of the mass of the viscous polymer PVA and acid-insoluble lignin to the mass of cellulose is 0.69 (the mass ratio of cellulose and viscous polymer is 1.45), its static bending strength and elastic modulus are far better than the static bending ...

Embodiment 3

[0071] 1. Cook the wood chips with 13% NaOH solution at 75°C for 10-12 hours, and then rub and refine the pulp to obtain a wood color pulp with a moisture content of 60% and a pH of 9-10, and measure the fiber in the wood color pulp (by dry weight). The mass content of cellulose (containing hemicellulose) was 83.07%, and the content of acid-insoluble wood was 6.02%. , supplement the by-product sodium lignin solution, mix evenly in proportion, acidify, wash and dry.

[0072] 2. Add a certain proportion of polyvinyl alcohol with a concentration of 2% according to the proportion, stick kraft paper with a thickness of 0.4mm on the upper and lower layers, and use 4g of styrene-acrylic emulsion for the adhesive layer.

[0073] 3. The product is obtained by hot pressing, pressure-holding cooling, and the specific properties are shown in Table 4.

[0074] Table 4 Preparation conditions and product properties of natural color paste materials

[0075]

[0076] The results in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com