Carbon nano onion film-based super capacitor used in alternating current line filtering field

A carbon nano-onion and supercapacitor technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of large volume, low RC time constant and relaxation time constant, and low volume of aluminum electrolytic capacitors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

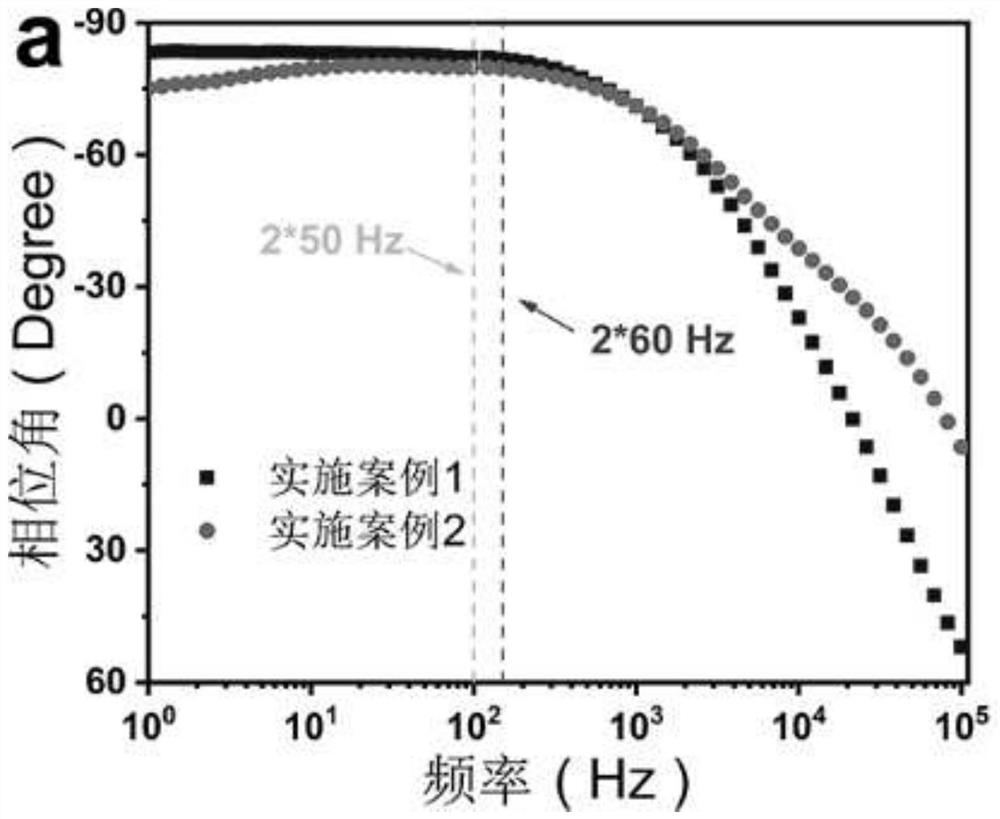

Embodiment 1

[0057] A preparation method of carbon nano onion film, comprising the following steps:

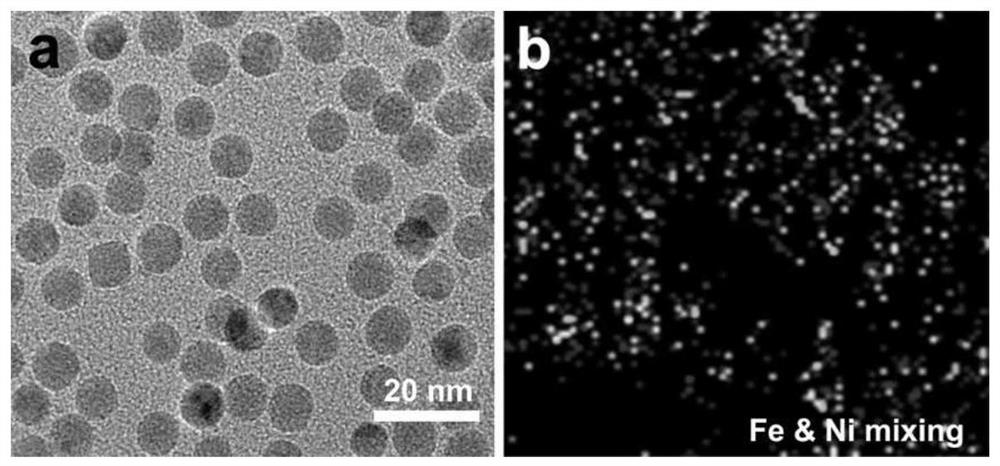

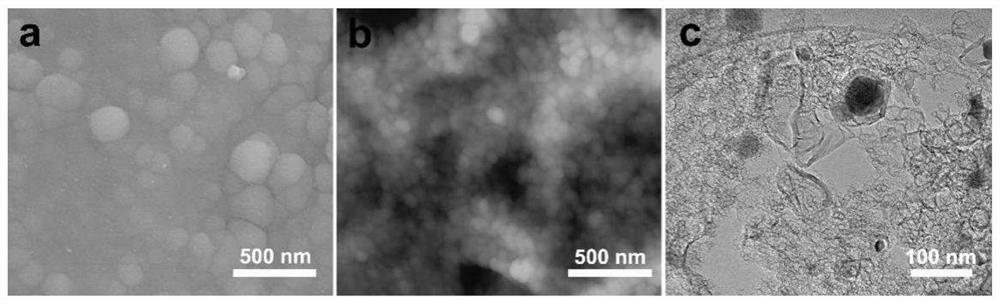

[0058] 1) Mix 0.541g of ferric chloride hexahydrate, nickel chloride hexahydrate and sodium oleate (providing oxidation function) as a solid, mix the solid with the first solution, heat at 60°C for 6 hours, add 40mL of deionized water Centrifuge to separate the liquid layers, and then keep warm at 100°C for 1 hour to remove water to obtain the second solution, wherein the first solution is a mixture of absolute ethanol, deionized water and n-hexane, calculated in parts by volume , the ratio of absolute ethanol, deionized water and normal hexane in the first solution is 1:1:2, and by mass parts, the ratio of ferric chloride hexahydrate, nickel chloride hexahydrate and sodium oleate is 1: 1:4, according to the amount of substance, the ratio of solid to first solution is 1:1.5;

[0059] 2) Mix the second solution with 1-octadecene and oleic acid, and incubate at 120°C for 30 minutes in a nit...

Embodiment 2

[0066] A preparation method of carbon nano onion film, comprising the following steps:

[0067] 1) Mix 1.082g ferric chloride hexahydrate, nickel chloride hexahydrate and sodium oleate (providing oxidation function) and make it solid, mix the solid with the first solution, heat at 50°C for 4 hours, add 50mL deionized water Centrifuge to separate the liquid layers, and then incubate at 100°C for 1.5 hours to remove water to obtain a second solution, wherein the first solution is a mixture of absolute ethanol, deionized water and n-hexane, calculated in parts by volume , the ratio of dehydrated ethanol, deionized water and normal hexane in the first solution is 1:1:2, by mass parts, the ratio of iron chloride hexahydrate, nickel chloride hexahydrate and sodium oleate is 2: 1:4, according to the amount of substance, the ratio of solid to first solution is 1:2;

[0068] 2) Mix the second solution with 1-octadecene and oleic acid, and incubate at 110°C for 40 minutes in a nitrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com