A kind of polymer composite protective film loaded with nano antibacterial peptide, preparation method and application

An antimicrobial peptide and protective film technology, which is applied in the field of functional polypolymer composite film materials, can solve the problem of no obvious biodegradability of materials, achieve high loading efficiency and cell uptake rate, low cytotoxicity, and improve antibacterial The effect of anti-toxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]The present embodiment provides a method for preparing a nano-antibacterial peptide-loaded polymeric composite protective film, comprising the following steps:

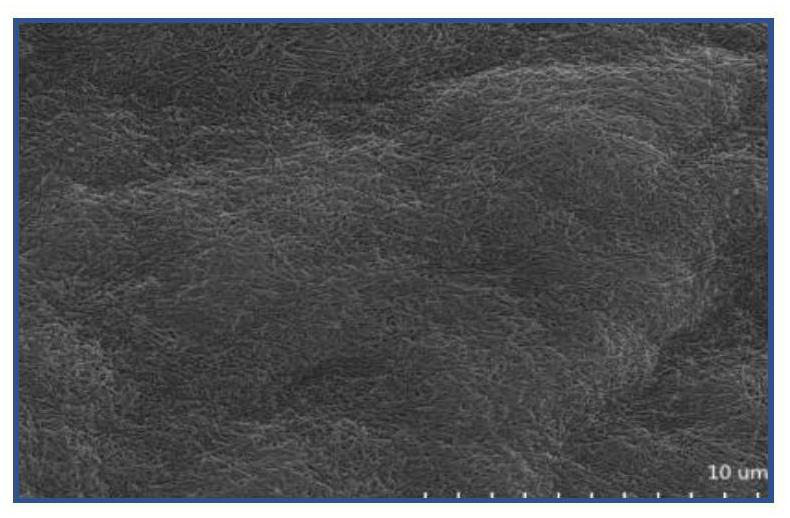

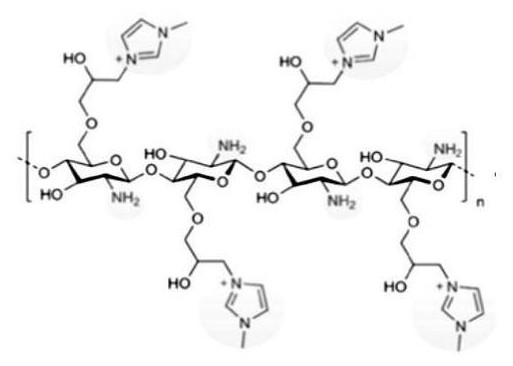

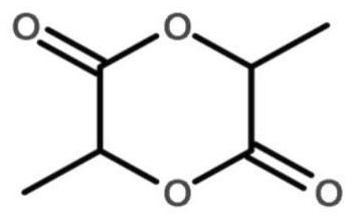

[0033] S1: Preparation of polymeric composite protective film and self-assembled nanobacterial peptides

[0034] A. Pour 0.5 to 4.1 parts by mass of HACC and 0.8 to 4.1 parts by mass of PLA into 81.2 to 83.3 parts by mass of pure water, and stir at 60°C and 99 rpm. Stir thoroughly for 30 minutes to obtain a HACC / PLA multipolymer mixed solution; then pour 25.6 to 30.7 parts of the HACC / PLA multipolymer mixed solution into 74.4 to 69.3 parts of the additive solution, and fully stir at 37°C and a stirring speed of 99 rpm. Mix well for 30 minutes, pour the polymer compound solution into a clean sterilization tray, let it stand for 1 hour in a sterile fume hood, and then put it into a drying box to dry for 2 hours. Peel off the polymeric composite protective film, as attached figure 1 The additive solution contains...

Embodiment 2

[0048] The present embodiment provides a method for preparing a nano-antibacterial peptide-loaded polymeric composite protective film, comprising the following steps:

[0049] S1: Preparation of polymeric composite protective film and self-assembled nanobacterial peptides

[0050] A. Pour 4.1 parts by mass of HACC and 2.7 parts of PLA into 83.3 parts of pure water, and fully stir at 60°C and 99 rpm stirring speed for 30 minutes to obtain a HACC / PLA multipolymer mixed solution; then add 30.7 parts of HACC / Pour the PLA polymixture into 69.3 parts of the additive solution, fully stir and mix for 30 minutes at 37°C and a stirring speed of 99rpm. After the polymixture is poured into a clean sterilization dish, place it in a sterile fume hood. After standing and casting for 1 hour, put it into a drying box to dry for 2 hours. After the drying is completed, gently peel off the dried material to obtain a polymeric composite protective film; the additive solution contains the followin...

Embodiment 3

[0061] A preparation method of a nano-antibacterial peptide-loaded polymer composite protective film, comprising the following steps:

[0062] S1: Preparation of polymeric composite protective film and self-assembled nanobacterial peptides

[0063] A. Pour 3.8 parts by mass of HACC and 2.9 parts of PLA into 83.3 parts of pure water, and fully stir for 30 minutes at 60°C and 99 rpm stirring speed to obtain a HACC / PLA multipolymer mixed solution; then add 30.7 parts of HACC / Pour the PLA polymixture into 69.3 parts of the additive solution, fully stir and mix for 30 minutes at 37°C and a stirring speed of 99rpm. After the polymixture is poured into a clean sterilization dish, place it in a sterile fume hood. After standing and casting for 1 hour, put it into a drying box to dry for 2 hours. After the drying is completed, gently peel off the dried material to obtain a polymeric composite protective film; the additive solution contains the following components by mass: 0.8-1.8 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com