Preparation method of UPE porous membrane

A technology of porous membrane and liquid membrane, which is applied in the field of membrane materials, can solve the problems of uneven distribution of separation membrane pore size, limit the development of UPE separation membrane, and poor capture ability of impurity particles, and achieve convenient preparation method, great economic value, suitable for The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

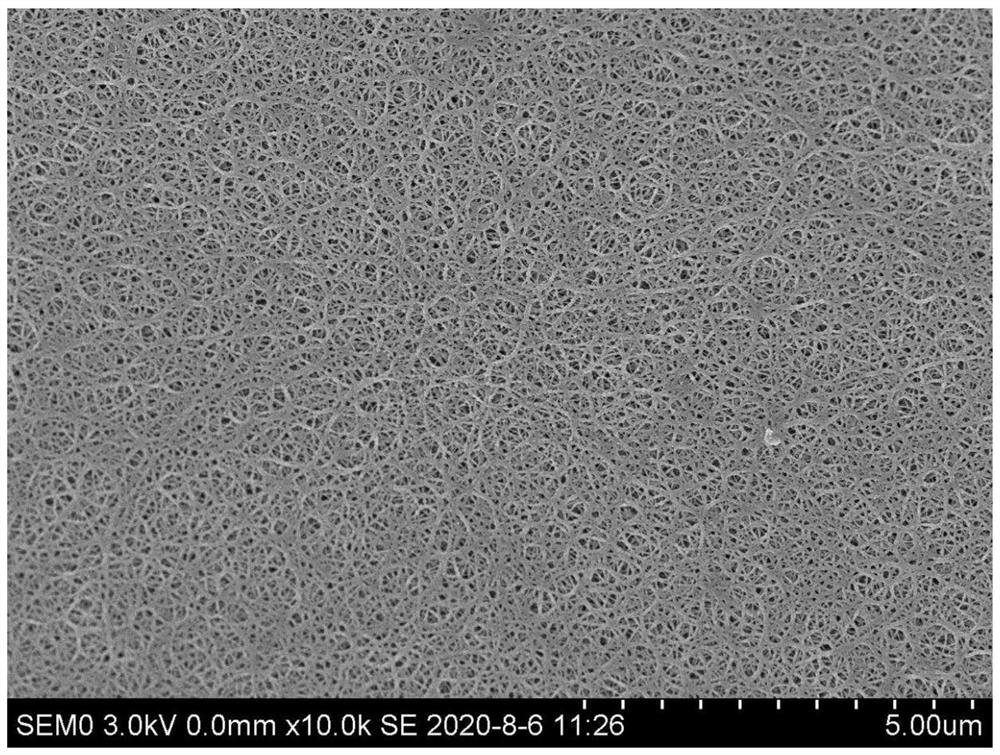

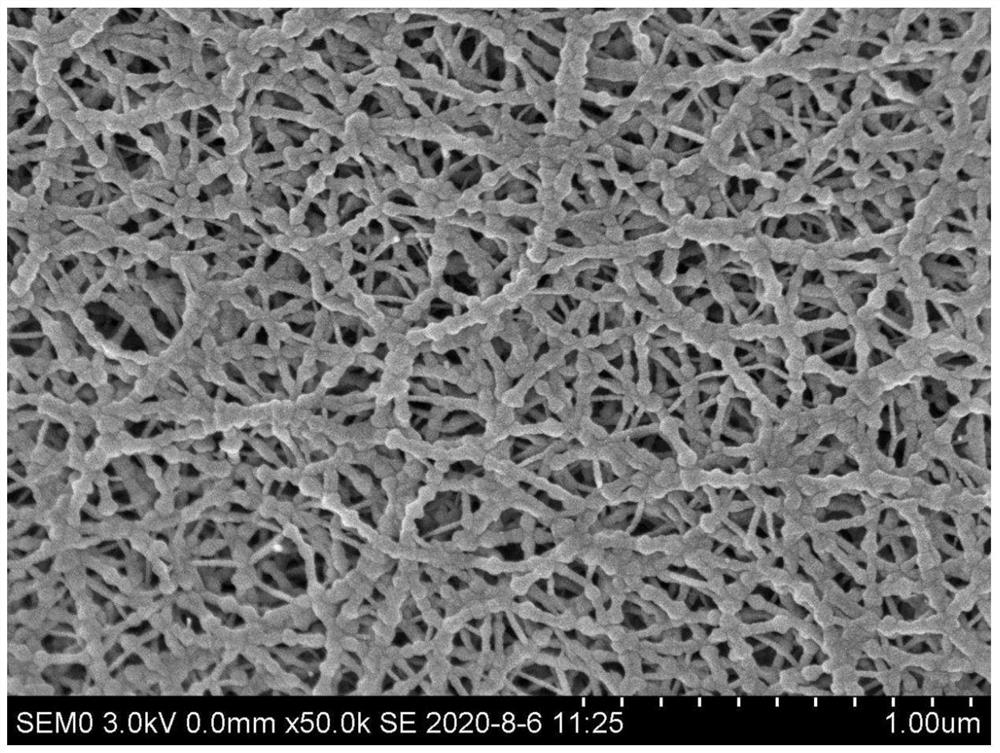

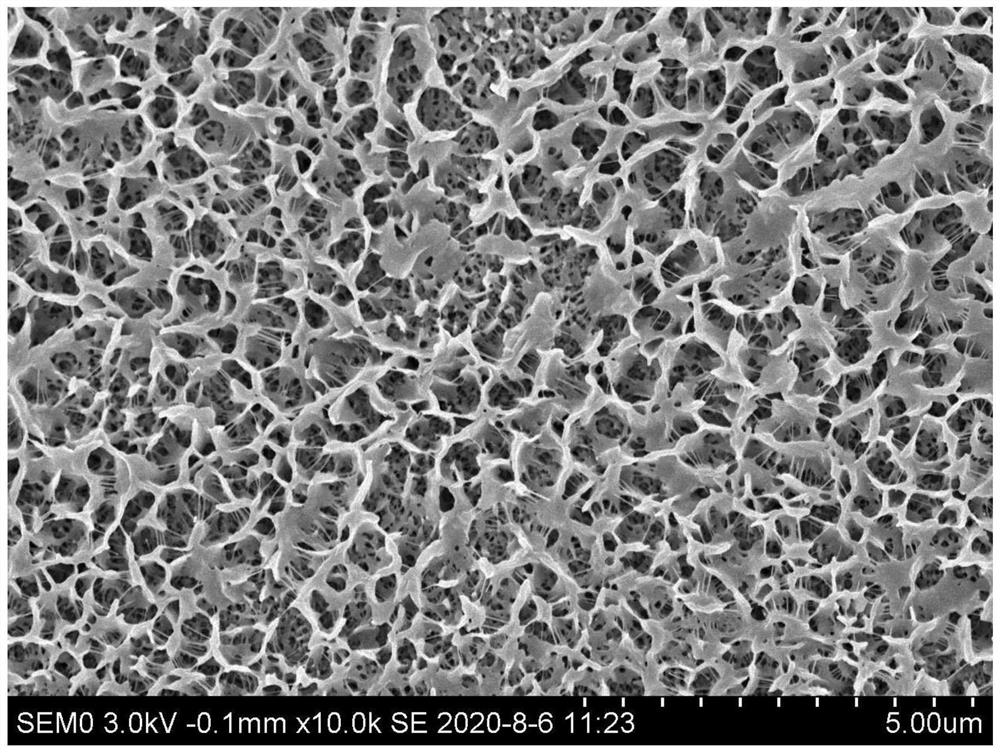

Image

Examples

Embodiment 1

[0055] A kind of preparation method of UPE porous film, comprises the following steps:

[0056] S1: Add polyethylene resin to the solvent system composed of compound A and compound B, stir and mix, and mix uniformly to form a mixed material; wherein the polyethylene resin is an ultra-high molecular weight polyethylene with a mass average molecular weight of 4 million; The bulk density of vinyl resin is 0.26g / cm 3 ; Compound A is a non-solvent for polyethylene resin; Compound B is a solvent for polyethylene resin; Compound A is dioctyl adipate, and Compound B is paraffin oil;

[0057] The mixed material comprises the following components by weight: polyethylene resin: 14 parts; compound A: 58 parts; compound B: 28 parts;

[0058] S2: Put the mixed material into the extruder at a temperature of 160-250°C to heat, melt and knead for 20 minutes to form a casting liquid, and then extrude through a die to form a liquid film; the extrusion temperature of the die is 235 ℃; the extru...

Embodiment 2

[0064] A kind of preparation method of UPE porous film, comprises the following steps:

[0065] S1: Add polyethylene resin to the solvent system composed of compound A and compound B, stir and mix, and mix uniformly to form a mixed material; compound A is a non-solvent for polyethylene resin; compound B is a solvent for polyethylene resin; compound A It is dimethyl phthalate; the compound B is white oil; the polyethylene resin is composed of 75% by mass of ultra-high molecular weight polyethylene with a mass average molecular weight of 4.5 million and 25% by mass with a mass average molecular weight of 1.5 million And the density is 0.92-0.98g / cm 3 Composition of high-density polyethylene; bulk density of polyethylene resin 0.22g / cm 3 ;

[0066] The mixed material comprises the following components by weight: polyethylene resin: 20 parts; compound A: 53 parts; compound B: 27 parts;

[0067] S2: Heat, melt and knead the mixed materials at a temperature of 180-260°C for 28 mi...

Embodiment 3

[0073] A kind of preparation method of UPE porous film, comprises the following steps:

[0074] S1: Add polyethylene resin to the solvent system composed of compound A and compound B, stir and mix, and mix uniformly to form a mixed material; the polyethylene resin is composed of 75% by mass of ultra-high molecular weight polystyrene with a mass average molecular weight of 4 million. Ethylene and 25 mass % have a mass average molecular weight of 1.2 million and a density of 0.92-0.98 g / cm 3 Composition of high-density polyethylene; bulk density of polyethylene resin 0.24g / cm 3 ; Compound A is a non-solvent for polyethylene resin; Compound B is a solvent for polyethylene resin; Compound A is dimethyl carbonate, and Compound B is decahydronaphthalene;

[0075] The mixed material comprises the following components by weight: polyethylene resin: 16 parts; compound A: 59 parts; compound B: 25 parts;

[0076] S2: Heat, melt and knead the mixed materials at a temperature of 165-250°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com