Production process of silicon-based sunscreen and heat-insulation powder

A technology of sun protection and heat insulation and production technology, which is applied in the field of coatings and can solve the problems of increased thermal conductivity and reduced heat insulation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

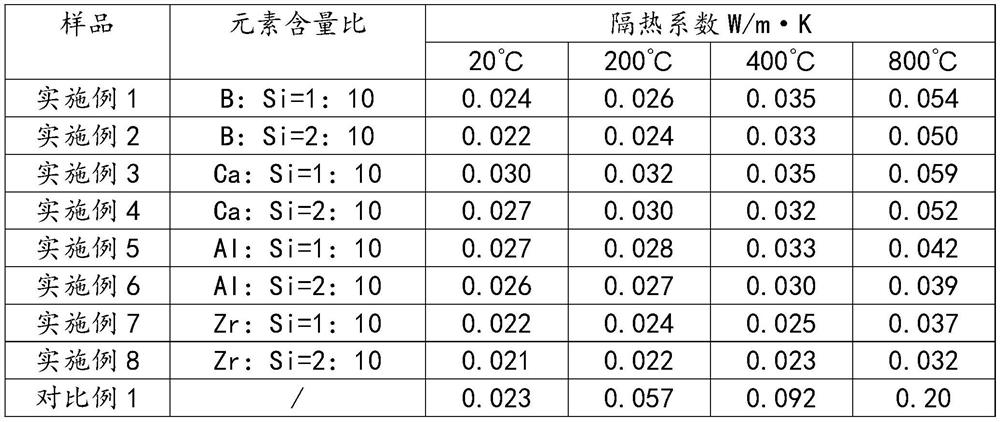

Examples

Embodiment 1

[0024] This embodiment is a production process of silicon-based sunscreen and heat insulation powder, which includes the following steps:

[0025] Step 1: Add water glass and ethanol aqueous solution to a three-necked flask equipped with a stirrer and a constant pressure dropping funnel, stir for 20 minutes at a stirring rate of 300r / min, and then ion-exchange the stirred product with a cation exchange resin , to obtain the intermediate product A; control the dosage ratio of water glass and ethanol aqueous solution to be 0.40mol: 1.0L, ethanol aqueous solution is the solution formed by absolute ethanol and deionized water according to the volume ratio of 1:8, and the ion exchange resin is strongly acidic Styrene-based cation exchange resins;

[0026] Step 2: Add the dopant dropwise to the intermediate product A, continue to stir for 20 minutes, add an alkali catalyst to adjust the pH of the reaction system to 5.0, then continue to stir for 3 minutes, leave it to stand for agin...

Embodiment 2

[0032] This embodiment is a production process of silicon-based sunscreen and heat insulation powder, which includes the following steps:

[0033] Step 1: Add water glass and ethanol aqueous solution to a three-necked flask equipped with a stirrer and a constant pressure dropping funnel, stir for 30 min at a stirring rate of 500 r / min, and then ion-exchange the stirred product with a cation exchange resin , to obtain the intermediate product A; control the dosage ratio of water glass and ethanol aqueous solution to be 0.40mol: 1.0L, ethanol aqueous solution is the solution formed by absolute ethanol and deionized water according to the volume ratio of 1:8, and the ion exchange resin is strongly acidic Styrene-based cation exchange resins;

[0034] Step 2: Add the dopant dropwise to the intermediate product A, continue to stir for 30 minutes, add an alkali catalyst to adjust the pH of the reaction system to 5.5, then continue to stir for 5 minutes, leave it to stand for aging, ...

Embodiment 3

[0040] This embodiment is a production process of silicon-based sunscreen and heat insulation powder, which includes the following steps:

[0041] Step 1: Add water glass and ethanol aqueous solution to a three-necked flask equipped with a stirrer and a constant pressure dropping funnel, stir for 20 minutes at a stirring rate of 300r / min, and then ion-exchange the stirred product with a cation exchange resin , to obtain the intermediate product A; control the dosage ratio of water glass and ethanol aqueous solution to be 0.40mol: 1.0L, ethanol aqueous solution is the solution formed by absolute ethanol and deionized water according to the volume ratio of 1:8, and the ion exchange resin is strongly acidic Styrene-based cation exchange resins;

[0042] Step 2: Add the dopant dropwise to the intermediate product A, continue to stir for 20 minutes, add an alkali catalyst to adjust the pH of the reaction system to 5.0, then continue to stir for 3 minutes, leave it to stand for agin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com