Nanometer blocking agent and preparation method thereof

A nano plugging agent and emulsifier technology, applied in the field of oil drilling, can solve the problems of small force between nanoparticles and formation, affecting the plugging effect, easy to separate again, etc., to improve the heat resistance effect, improve the plugging effect, The effect of increasing the consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

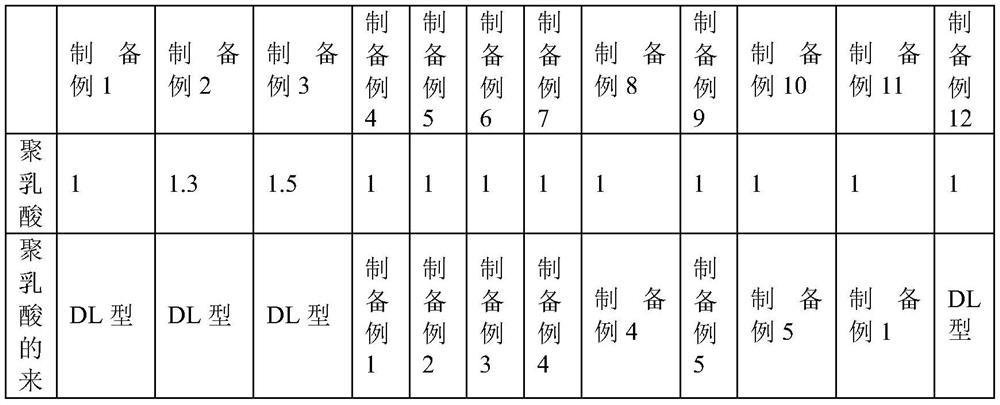

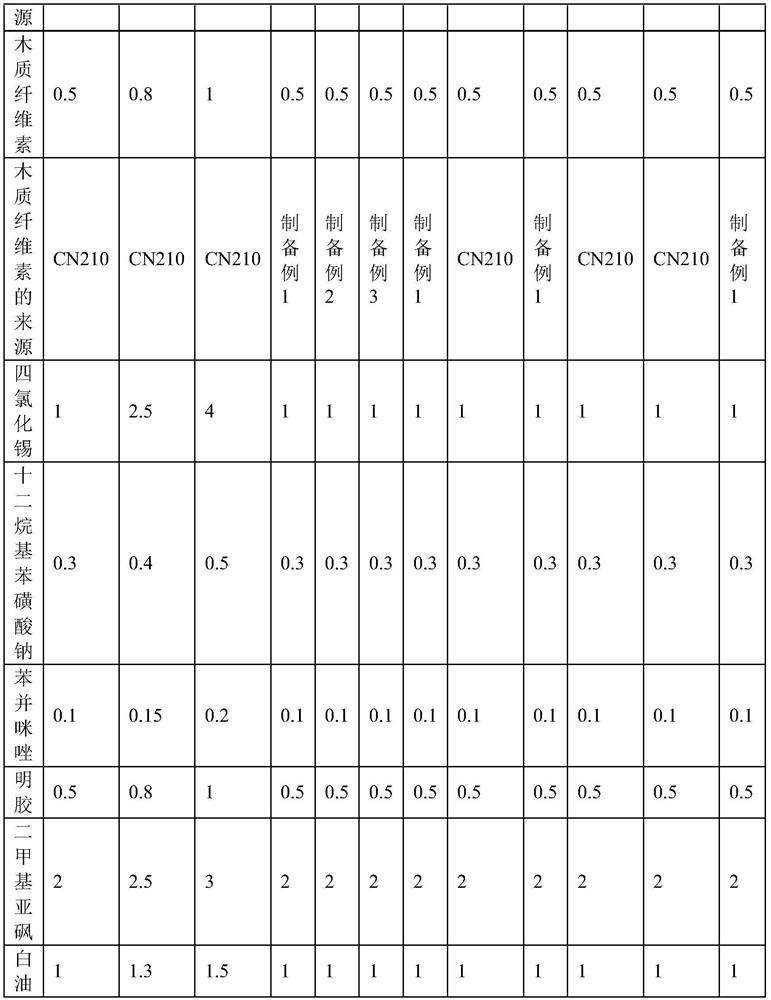

preparation example 1-5

[0042] The polylactic acid preparation example 1-5 is selected from Shandong Institute of Medical Devices, the molecular weight is 30000, and the model is DL; 1-octyl-3-methylimidazolium tetrafluoroborate is selected from Linzhou Keneng Materials Technology Co., Ltd., CAS No. 86560-94-6; triallyl isocyanurate is selected from Guangxi Tengjun Biotechnology Co., Ltd., product number is TJ-011-1; tin powder is selected from Nangong Dinghong Metal Materials Co., Ltd., the product number is 354, and 1-ethyl-3-methylimidazolium tetrafluoroborate is selected from Mooney Chemical Technology (Shanghai) Co., Ltd., and the CAS number is 143314-16-3.

preparation example 1

[0043] Preparation Example 1: (1) Dissolve 2kg of polylactic acid in 50kg of chloroform, add 1kg of 1-octyl-3-methylimidazolium tetrafluoroborate, and place it on a cobalt-60 source with an irradiation rate of 2.2kGy / h After irradiating 10kGy, precipitate with methanol and dry at 60°C for 2h. The mass ratio of polylactic acid and 1-octyl-3-methylimidazolium tetrafluoroborate is 2:1; (2) the step (1) The resultant is mixed with 1kg of triallyl isocyanurate, 0.2kg of tin powder and 2kg of solvent, heated to 190°C under vacuum, reacted for 2h, cooled to 140°C, kept for 0.5h, cooled to room temperature, pulverized, triene The mass ratio of propyl isocyanurate, tin powder, solvent and polylactic acid is 0.5:0.1:1:1, and the solvent is dichloromethane.

preparation example 2

[0044] Preparation Example 2: (1) Dissolve 3.5kg of polylactic acid in 55kg of chloroform, add 1kg of 1-octyl-3-methylimidazolium tetrafluoroborate, and use a cobalt-60 source with an irradiation rate of 2.3kGy / h After irradiating 10kGy, precipitate with methanol and dry at 70°C for 1.5h. The mass ratio of polylactic acid and 1-octyl-3-methylimidazolium tetrafluoroborate is 3.5:1; (2) the step ( 1) Mix the resultant with 2.1kg of triallyl isocyanurate, 0.7kg of tin powder and 7kg of solvent, vacuumize and heat to 190°C, react for 2h, cool down to 140°C, keep warm for 0.5h, cool down to room temperature, and pulverize , the mass ratio of triallyl isocyanurate, tin powder, solvent and polylactic acid is 0.6:0.2:2:1, and the solvent is dichloromethane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com