Preparation and application of high-activation charcoal based on heat and cobalt complex modification

A biochar and complex technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, water pollutants, etc., can solve the kinetics of difficult to achieve activation and degradation of organic pollutants Increase and other problems, to achieve the effect of low price, simple preparation method and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

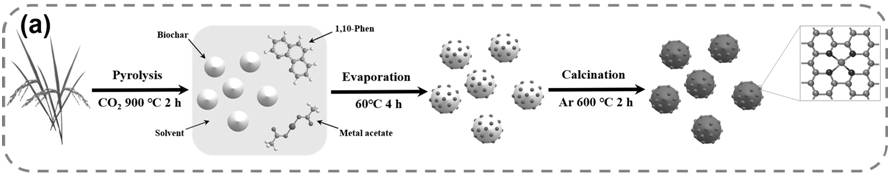

[0030] The preparation of a highly activated biochar based on heat and cobalt complex modification of the present embodiment comprises the following steps:

[0031] (1) Using straws of rice, wheat and other crops as raw materials, crush and sieve, calcinate at 900 °C for 2 hours in an atmosphere of carbon dioxide, wash and dry with hydrochloric acid to obtain biochar;

[0032] (2) Cobalt acetate (0.1 mM, 0.25 mM, 0.5 mM, 1.0 mM, 1.5 mM, 2.0 mM and 2.5 mM) and 1,10-phenanthroline (0.3 mM, 0.75 mM, 1.5 mM, 3.0 mM, 4.5 mM, 6.0 mM and 7.5 mM), after ultrasonic dispersion, calcined biochar was added, evaporated and stirred in a water bath for 4 hours, and the obtained complex was dried in an oven;

[0033] (3) Grind the dried composite into powder, calcinate at 600 °C for 2 hours in an argon atmosphere, take it out after room temperature, and seal it with an inert gas for storage;

[0034] Further, the biochar precursor used in the step (1) is a kind of straw of crops such as rice...

Embodiment 2

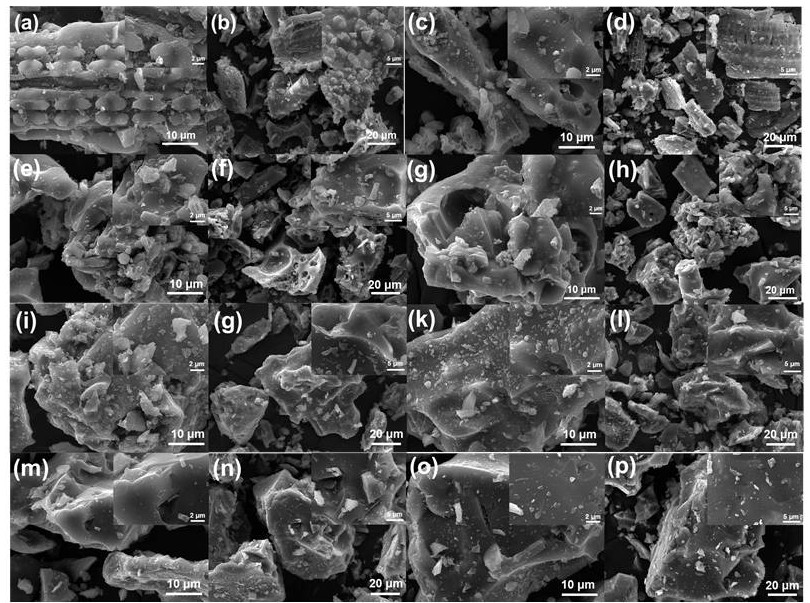

[0038] This example is used to illustrate the morphological characterization of thermally and cobalt complex modified biochar.

[0039] Such as figure 2 Shown are scanning electron microscope images of biochars with different loadings of cobalt complexes after calcination, (a-b) are biochar precursors, (c-d) are 0.1 mM cobalt acetate loading, (e-f) are 0.25 mM cobalt acetate loading (g-h) is 0.5 mM cobalt acetate loading, (i-g) is 1.0 mM cobalt acetate loading, (k-l) is 1.5 mM cobalt acetate loading, (m-n) is 2.0 mM cobalt acetate loading, (o-p) is 2.5 mM cobalt acetate loading. After being modified and calcined by the cobalt complex, the biochar no longer has the original structure. Since the cobalt complex melts under heating conditions, the surface of the biochar is covered, and the metal elements are loaded on the surface of the biochar. And with the increase of load, it is more difficult to see the original result of biochar and the degree of agglomeration is more obvi...

Embodiment 3

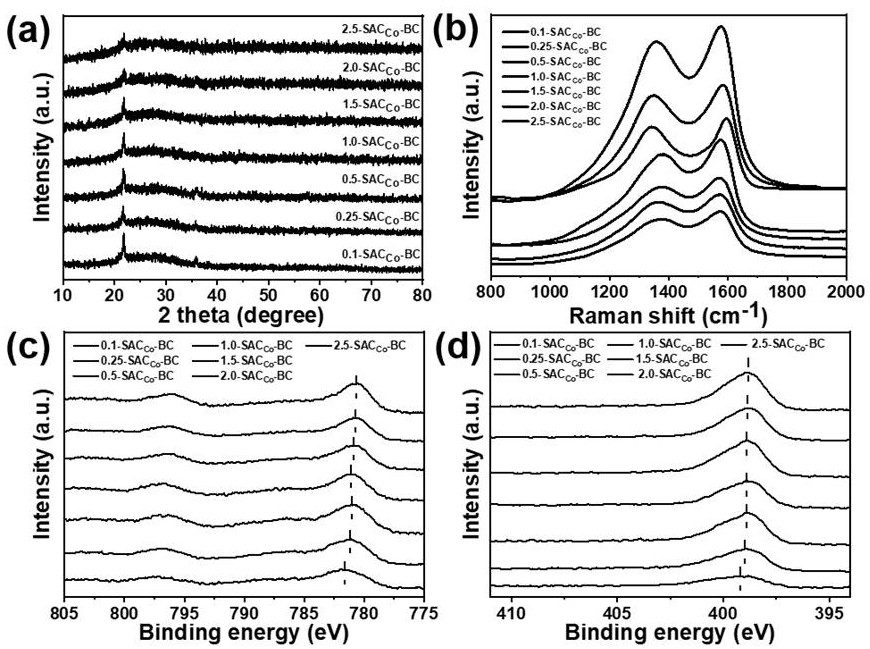

[0041] This example serves to illustrate the structural characterization of thermally and cobalt complex modified biochar.

[0042] Such as image 3 As shown in -a, it is shown by X-ray diffraction that no characteristic peaks appear after the introduction of cobalt complexes, and the graphite phase results and the existence of some silica impurities are maintained, further indicating that cobalt can reach atomic-level distribution on the surface of biomass , no corresponding characteristic peaks appear.

[0043] image 3 The Raman results in -b show that with the increase of the amount of cobalt loaded on the biochar, the degree of graphitization (ID / IG) first increases and then decreases, and the graphitization degree of 0.5 mM cobalt acetate is the largest .

[0044] Such as image 3As shown in -c and d, the binding energy of the 2p 3 / 2 peak of cobalt in the biochar with different loads of cobalt complexes showed a trend of decreasing first and then increasing, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com