Silver-titanium dioxide filler doped polyvinylidene fluoride dielectric composite film and preparation method thereof

A polyvinylidene fluoride and dielectric composite technology, applied in the field of dielectric composite films, can solve the problems of composite material loss and leakage current increase, material flexibility damage, breakdown field strength drop and other problems, and achieve the improvement of field strength and polarization. , large polarization strength, improve the effect of interface polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

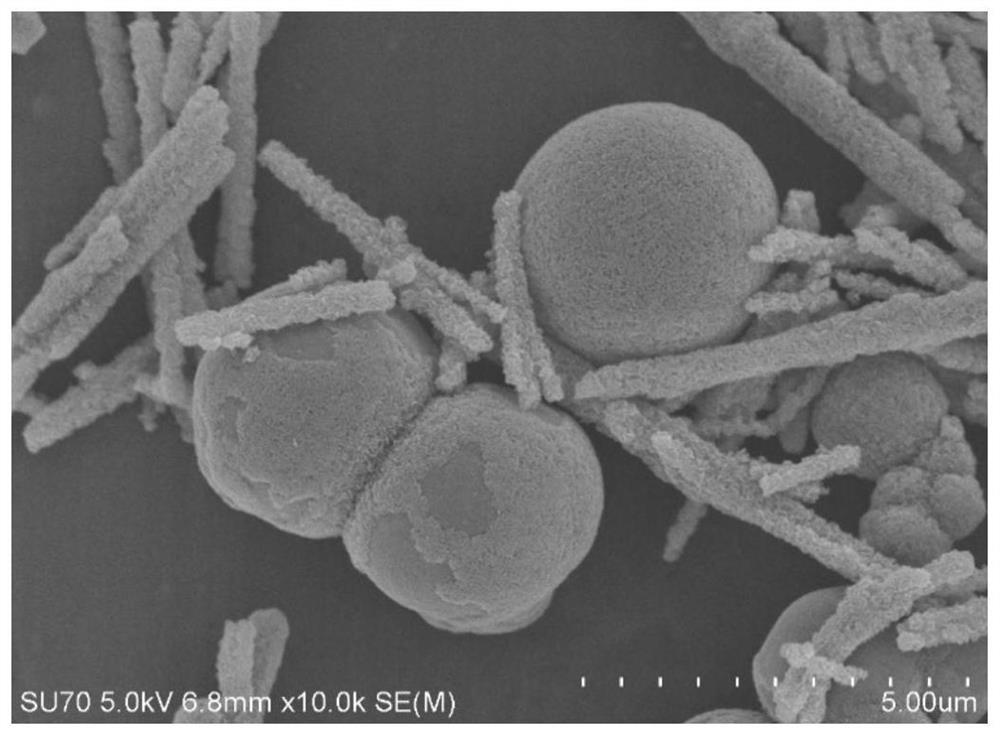

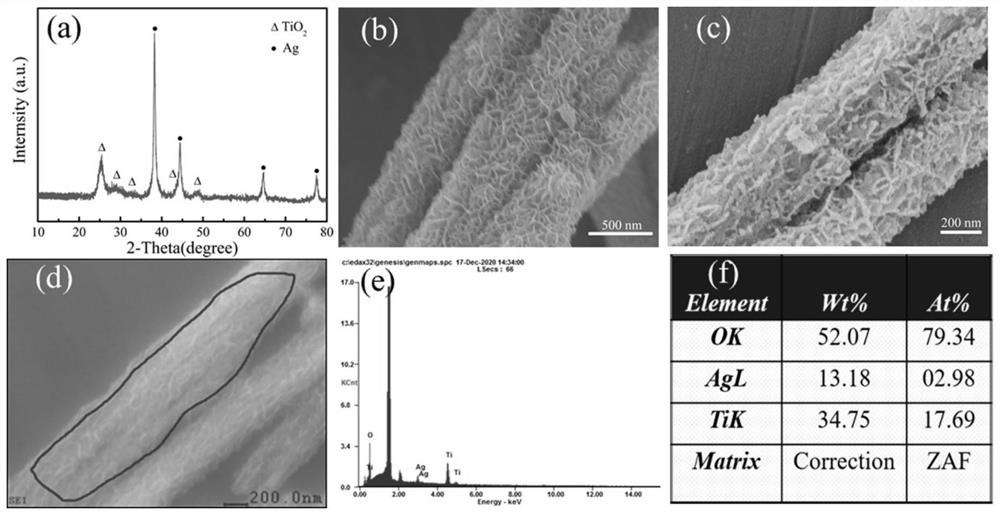

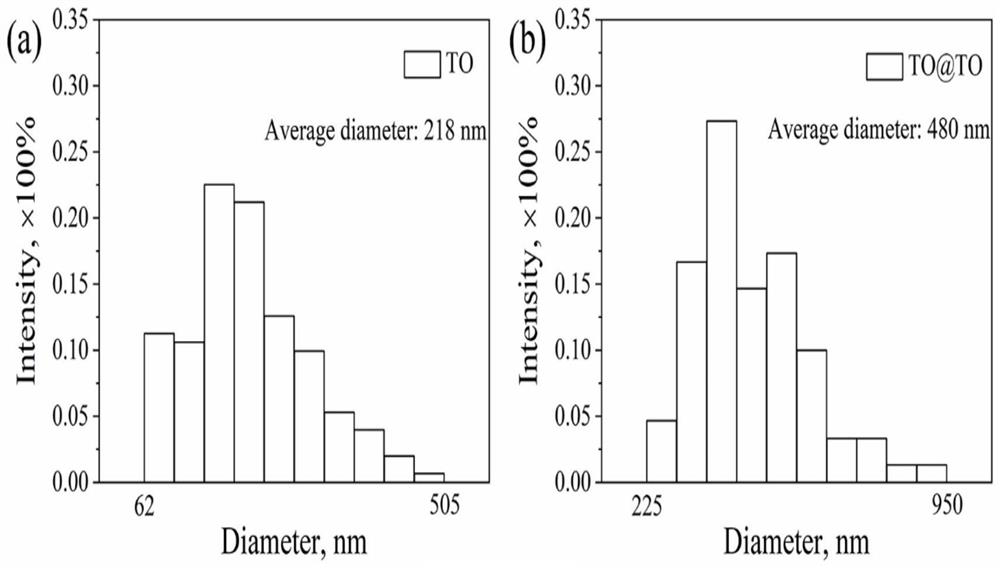

[0037] A dielectric composite film with silver-titanium dioxide filler doped with polyvinylidene fluoride, the composite film is composed of silver-titanium dioxide (Ag@TO@TO) filler filled in polyvinylidene fluoride matrix, silver-titanium dioxide filler core-shell structure, in which the core layer is one-dimensional titania nanowires (TO NWs) coated with bark-like flaky titania (p-TO), and the shell layer is silver nanoparticles (Ag NPs) modified on the surface of flaky titania ), the preparation process is as follows:

[0038] 1. Synthesize titanium dioxide nanowires (TO NWs) from titanium dioxide nanopowder by hydrothermal method, and dry it for later use, as follows: uniformly disperse titanium dioxide nanopowder in 10 M sodium hydroxide aqueous solution, ultrasonically disperse for 30 min, and then stir with magnetic force After 12 h, the mixture was transferred to a reaction kettle, put into a blast drying oven, heated at 200 °C for 24 h, taken out, cooled naturally, w...

Embodiment 2

[0046] Same as the above example 1, the difference is that in step 4, 0.00615 g Ag@TO@TO filler was dispersed in 3.5 mL of organic solvent N-N dimethylformamide (DMF), then ultrasonicated for 1 h, stirred for 2 h, and then added 0.5 g polyvinylidene fluoride (PVDF) was stirred for 24 h, and a dielectric composite film with a silver-titania filler volume fraction of 1% silver-titania filler doped polyvinylidene fluoride was prepared by solution casting method.

Embodiment 3

[0048] Same as the above example 1, the difference is that in step 4, 0.01848 g Ag@TO@TO filler was dispersed in 3.5 mL of organic solvent N-N dimethylformamide (DMF), then ultrasonicated for 1 h, stirred for 2 h, and then added 0.5 g polyvinylidene fluoride (PVDF) was stirred for 24 h, and a dielectric composite film with silver-titania filler doped PVDF with a volume fraction of 1.5% silver-titania filler was prepared by solution casting method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com