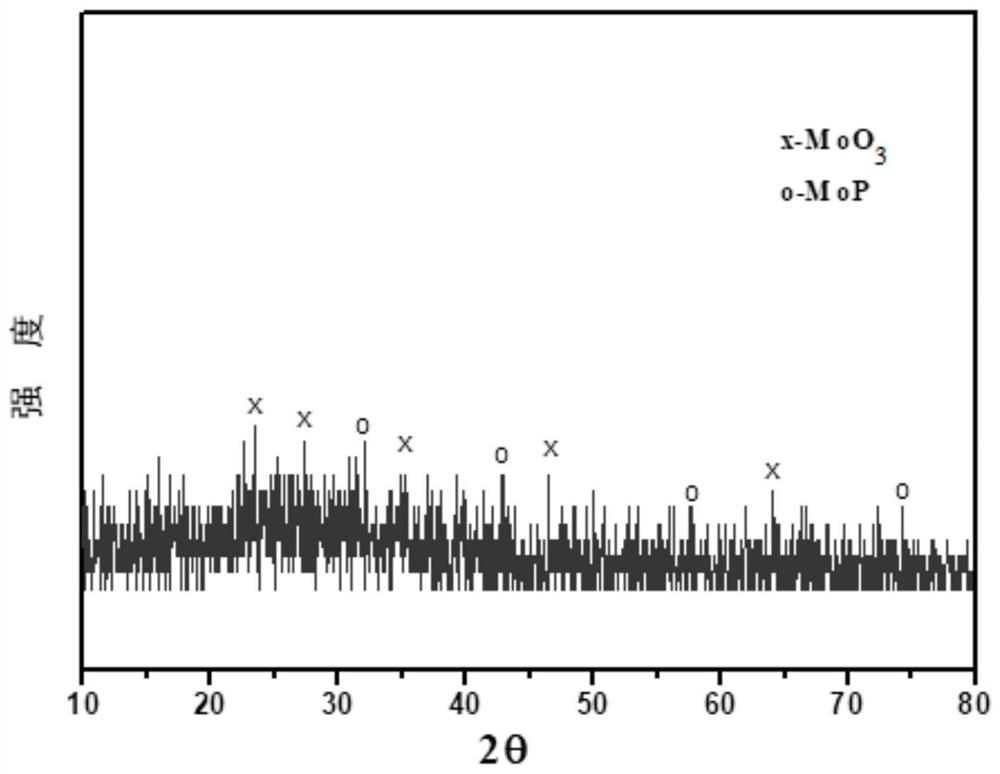

Preparation method and application of a binary heterostructure wave-absorbing material molybdenum oxide-molybdenum phosphide

A wave-absorbing material and heterogeneous structure technology, which is applied in the field of preparation of molybdenum oxide composite materials, can solve the problems of large amount of electromagnetic wave absorbing materials, high raw material prices and equipment costs, complicated preparation steps of molybdenum compounds, etc., and achieves easy implementation, The effect of low cost and wide coverage frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

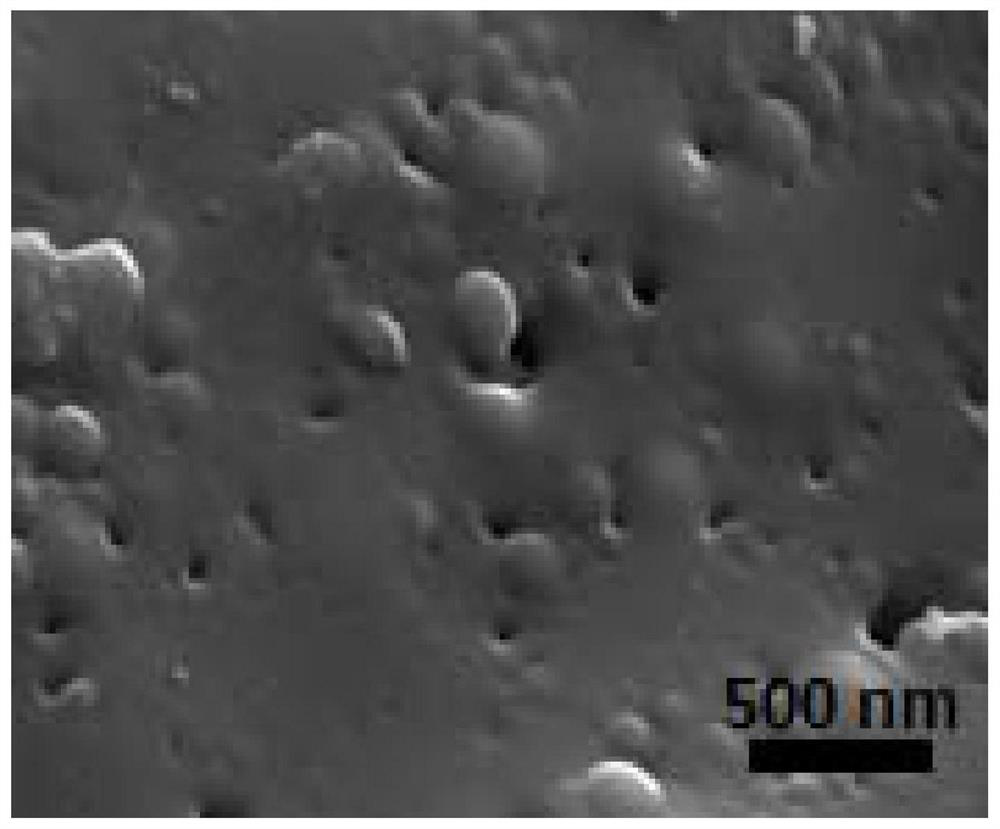

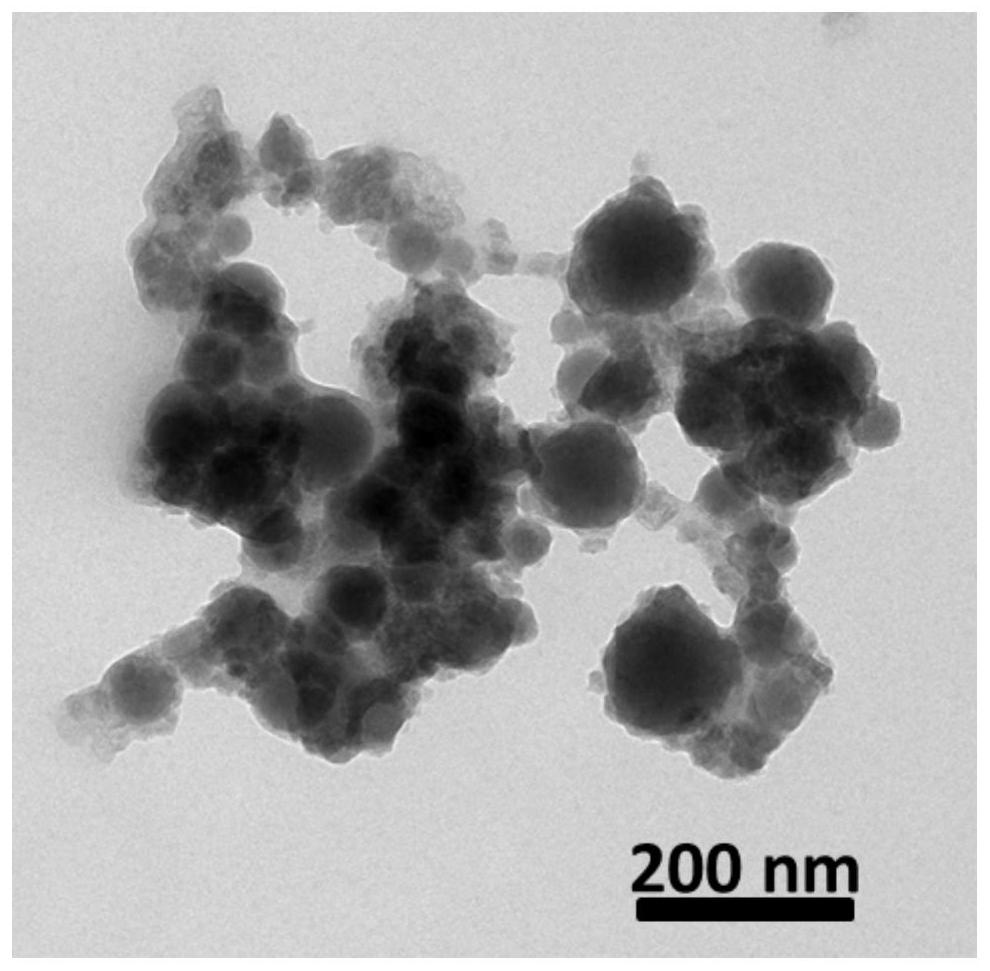

[0043] Specific implementation mode 1: In this implementation mode, a method for preparing a binary heterostructure wave-absorbing material molybdenum oxide-molybdenum phosphide is specifically completed according to the following steps:

[0044] 1. Preparation of organic molybdenum / hypophosphite mixed solution:

[0045] Add organic molybdenum and hypophosphite to the solvent, then stir, and then sonicate to obtain organic molybdenum / hypophosphite mixed solution;

[0046] 2. Add additives:

[0047] adding the additive into the organic molybdenum / hypophosphite mixed solution, and then stirring to obtain the reaction solution I;

[0048] 3. Add liquid paraffin:

[0049] ①. Add liquid paraffin to the reaction solution I, and then stir to obtain the reaction solution II;

[0050] 4. Hydrothermal reaction:

[0051] ①. Transfer the reaction solution II to a hydrothermal reaction kettle, and then conduct a hydrothermal reaction at a temperature of 180°C to 240°C to obtain the rea...

specific Embodiment approach 2

[0056] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the organic molybdenum described in step one is molybdenum acetylacetonate, molybdenum acetate, molybdenum naphthenate or molybdenum alkyl salicylate; The hypophosphite is ammonium hypophosphite, sodium hypophosphite or potassium hypophosphite; the solvent described in step one is oleylamine, triethanolamine or octadecylamine. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0057] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the molar ratio of organic molybdenum and hypophosphite described in step one is 1: (1~10); The mass ratio of the described organic molybdenum to the solvent is 1: (10-80); in step one, the organic molybdenum and hypophosphite are added to the solvent, and then the temperature is 60°C-100°C and the stirring speed is 50r / min Stirring at ~100r / min for 20min~40min, then ultrasonicating for 15min~30min at a temperature of 60~80°C and an ultrasonic power of 30W~50W to obtain an organic molybdenum / hypophosphite mixed solution. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com