Organic modification method for improving dispersity of graphite phase carbon nitride in lubricating oil

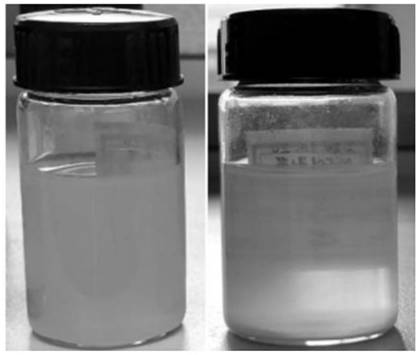

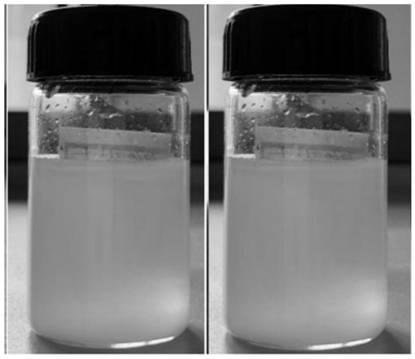

A graphite phase carbon nitride, organic modification technology, applied in the petroleum industry, lubricating compositions, additives, etc., can solve the problems of low compatibility between graphite phase carbon nitride and lubricating oil, reduce sedimentation, Improved dispersion effect and prevention of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

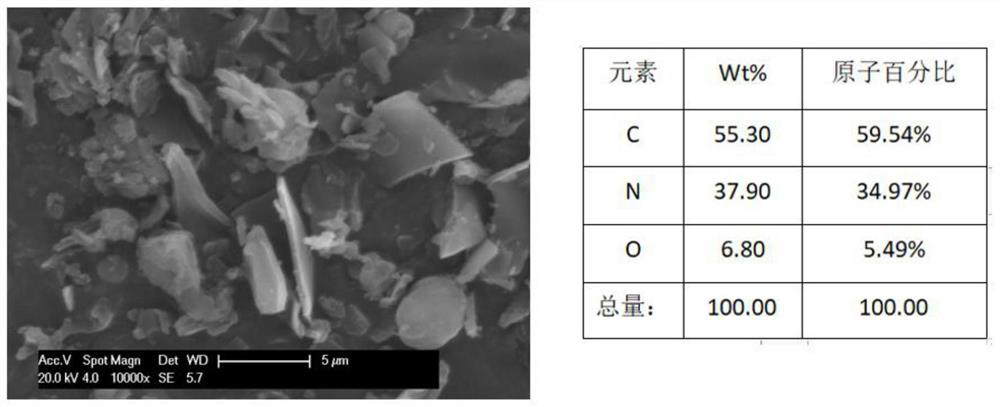

[0021] The organic modification method for improving the dispersibility of graphite phase carbon nitride in lubricating oil comprises the following steps: firstly, a certain amount of long carbon chain organic carboxylic acid, triethylamine, 1-ethyl-(3-diethylamine) Methylaminopropyl) carbodiimide hydrochloride (EDC.HCL) and 1-hydroxybenzotriazole (HOBT) were mixed into a certain amount of organic solvent, stirred in advance for several hours at room temperature, and then added graphite phase nitrogen The carbonized carbon is heated and refluxed for several hours at a certain temperature, and finally filtered, washed and dried to obtain an organically modified graphitic carbon nitride.

Embodiment 2

[0029] The long carbon chain organic carboxylic acid has a carbon chain atomic number of 12 to 30, the mass ratio of the long carbon chain carboxylic acid to the graphite phase carbon nitride is (10 to 30): 1, and the triethylamine to the graphite phase nitrogen The mass ratio of carbonized carbon is (5~20):1, the mass ratio of EDC.HCL to graphite phase carbon nitride is (2~20):1, and the mass ratio of HOBT to graphite phase carbon nitride is (2~15): 1. The organic solvent is N,N-dimethylformamide (DMF), and the mass ratio of DMF to graphitic carbon nitride is (600~1000): 1, and the organic modification method is as follows: After the chain organic carboxylic acid, EDC.HCL, HOBT, and triethylamine are mixed and added into DMF, the activation time is 1-3h under pre-stirring at room temperature. In the modification method, the heating and refluxing temperature after adding graphite phase carbon nitride is 40-40 80℃, heating time is 4~12h.

[0030] Dissolve 0.72g lauric acid (lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absorbance | aaaaa | aaaaa |

| Absorbance | aaaaa | aaaaa |

| Absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com