Preparation method of acesulfame potassium

A technology of acesulfame potassium and potassium ethoxide, applied in the direction of organic chemistry, etc., can solve the problems of low purity of acesulfame potassium, and it is difficult to further improve the product purity, and achieve the effect of improving the purity, reducing the content of inorganic impurities, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of acesulfame potassium provided by the application at least includes step S110 to step S120:

[0028] Salt-forming step S110: separating the sulfonated cyclization product solution into an organic phase and an inorganic phase, adding an ethanol solution of potassium ethoxide to the organic phase to perform a salt-forming reaction; wherein, the sulfonated cyclization product solution is acetoacetamide-N- The cycloaddition product of triethylamine sulfonate and sulfur trioxide is obtained by hydrolysis.

[0029] In this application, the sulfonated cyclization product refers to the process of preparing acesulfame potassium by the diketene-sulfur trioxide method. In the presence of sulfur trioxide, the acetylacetamide salt undergoes a cyclization reaction to form a cyclic sulfur trioxide plus compound. compound, and then the hydrolysis product (ASH) obtained by hydrolysis of the cyclic compound is a sulfonated ring closure product.

[0030] In the p...

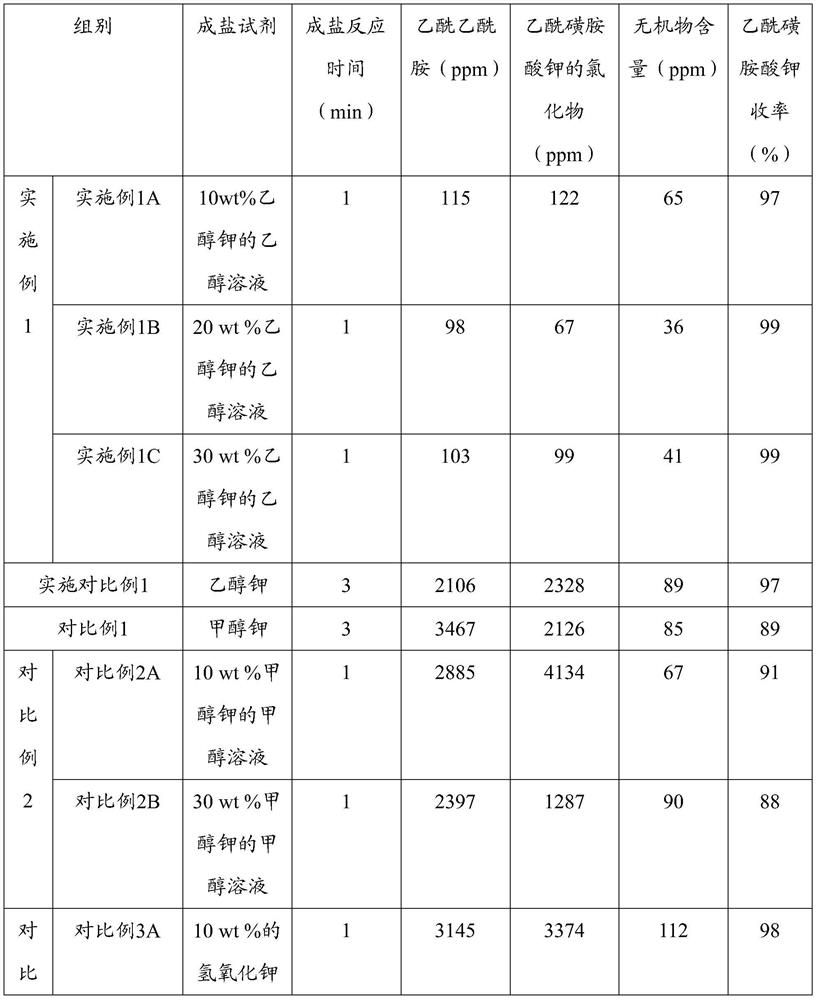

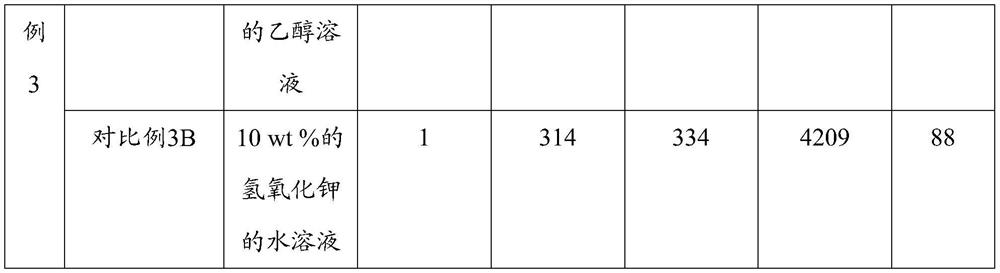

Embodiment 1( Embodiment 1A

[0076] Example 1 (Example 1A, Example 1B, Example 1C)

[0077] Salt-forming step: separating the above-mentioned sulfonated cyclization product solution into an organic phase and an inorganic phase, and adding a salt-forming reagent—a solution of potassium ethoxide in ethanol to the organic phase to carry out a salt-forming reaction. The specific reaction conditions are shown in Table 1.

[0078] Washing step: after the salt-forming reaction is completed, the solid product is obtained by filtration, and the solid product is washed with ethanol to obtain the crude product of acesulfame potassium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com