High-temperature anoxic catalytic combustion catalyst as well as preparation method and application thereof

A catalytic combustion and catalyst technology, which is applied in catalyst activation/preparation, combustion methods, physical/chemical process catalysts, etc. High temperature stability, increased activity, and the effect of multiple active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

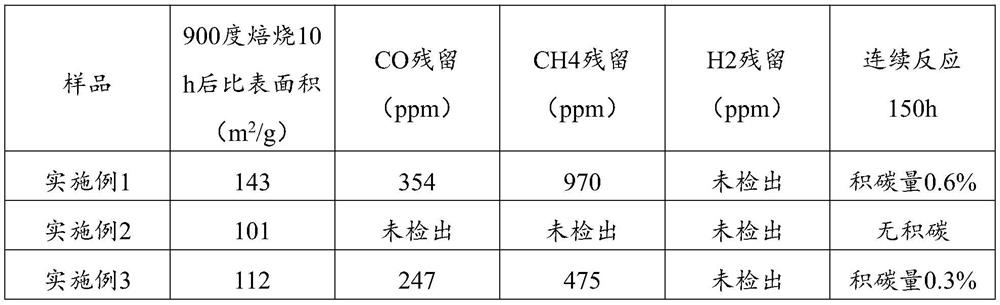

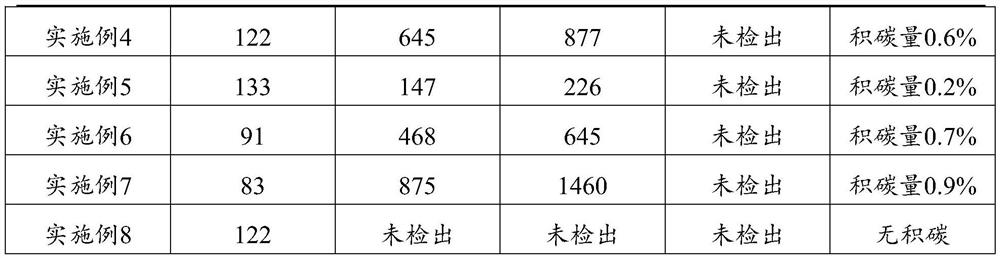

Examples

preparation example Construction

[0046] The present invention also provides a preparation method of the high-temperature anoxic catalytic combustion catalyst described in the above technical solution, comprising the following steps:

[0047] Mix soluble cerium salt, soluble zirconium salt, soluble yttrium salt, soluble lanthanum salt, urea and water, heat homogeneous precipitation reaction and the first hydrothermal reaction in sequence, and then carry out the first roasting of the obtained precipitated product to obtain the first carrier product;

[0048] Mix the first carrier product, water, ethyl acetate, citric acid, soluble noble metal salt and hydrazine hydrate, and undergo a reduction reaction to obtain the first dispersed product; the soluble noble metal salt includes soluble ruthenium salt and / or soluble platinum salt ;

[0049] Mix dodecylamine, the first dispersion product, solvent and tetraethyl orthosilicate, after self-assembly of polymerization reaction, add the soluble salt corresponding to t...

Embodiment 1

[0095] 45.39gCe(NO 3 ) 3 ·6H 2 O, 62.70g Zr(NO 3 ) 4 ·5H 2 O, 8.47g Y (NO 3 ) 3 ·6H 2 O, 6.7gLa(NO 3 ) 3 ·6H 2 Mix O and 454g of water to obtain a mixed metal salt solution, add 86.57g of urea (the total molar ratio of Ce, Zr, Y and La ions to urea is 1:5) and stir for 2h, and heat at 95°C to generate a homogeneous phase After 5 hours of precipitation reaction, hydrothermal reaction was carried out at 150°C for 24 hours, filtered, washed 6 times with deionized water, dried at 80°C for 6 hours, and calcined at 700°C for 2 hours to obtain 41.02 g of the first carrier product;

[0096] After mixing 41.02 g of the first carrier product and 12.3 g of water, add 0.38 g of RuCl 3 ·6H 2 O, 28.71g citric acid, 0.37g H 14 Cl 6 o 6 Pt and 16.4g of ethyl acetate were stirred for 3h, 0.19g of hydrazine hydrate was added, and a reduction reaction occurred. The conditions of the reduction reaction were stirring at room temperature, filtering, and mixing the resulting 41.3g sol...

Embodiment 2

[0100] 52.96g Ce(NO 3 ) 3 ·6H 2 O, 73.15g Zr(NO 3 ) 4 ·5H 2 O, 13.56gY (NO 3 ) 3 ·6H 2 O, 6.64gLa(NO 3 ) 3 ·6H 2Mix O and 529.6g of water to obtain a mixed metal salt solution, add 103.6g of urea (the total molar ratio of Ce, Zr, Y and La ions to urea is 1:5), stir for 2 hours, and heat at 90°C After homogeneous precipitation reaction for 6 hours, conduct hydrothermal reaction at 150°C for 24 hours, filter, wash with deionized water for 6 times, dry at 80°C for 6 hours, and roast at 800°C for 2 hours to obtain 48.5 g of the first carrier product;

[0101] After mixing 48.5 g of the first carrier product and 14.55 g of water, add 0.77 g of RuCl 3 ·6H 2 O, 33.95g citric acid, 0.21g H 14 Cl 6 o 6 Pt and 19.4g of ethyl acetate were stirred for 3 hours, 0.37g of hydrazine hydrate was added, and a reduction reaction occurred. The conditions of the reduction reaction were stirring at room temperature, filtering, and mixing the obtained 48.8g of solids with 32.33g of ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com