Alkali metal regulated hierarchical pore Au/ZSM-5 catalyst as well as synthesis method and application thereof

A technology of ZSM-5 and synthesis method, which is applied in the field of air pollution control, can solve the problems of limitation, high price, easy aggregation and easy deactivation of active centers, etc., and achieve the effects of dispersion promotion, large specific surface area, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for synthesizing the multi-level porous Au / ZSM-5 catalyst regulated by alkali metals, using the mesoporous phase alkali leaching modification method and the active phase ethylene glycol reduction doping method, the specific technical steps are as follows:

[0025] (1) Mix 12-13g of tetrapropylammonium hydroxide (TPAOH) solution with 12.5-13.5g of tetraethyl orthosilicate (TEOS), heat to 80-85°C, stir at 650-800rpm for 24-26h to obtain a solution ;

[0026] (2) After the solution obtained in step (1) is cooled to room temperature, NaOH (0.24-0.26g), Al(NO 3 ) 3 9H 2 A mixed solution of O (0.45-0.47g) and deionized water (4-5mL). After homogenization, transfer to a Teflon reactor and crystallize at 170°C for 24-26 hours to obtain a solution;

[0027] (3) Centrifuge the solution obtained in step (2) at 9000-11000 rpm, wash the obtained solid with deionized water, dry at 100-120°C overnight, and calcinate in a muffle furnace at 550-600°C for 10-11h to obtain p...

Embodiment 1

[0036] Example 1 Synthesis of supported noble metal catalytic materials and supported dual-functional component catalytic materials by alkali leaching method ethylene glycol reduction doping method

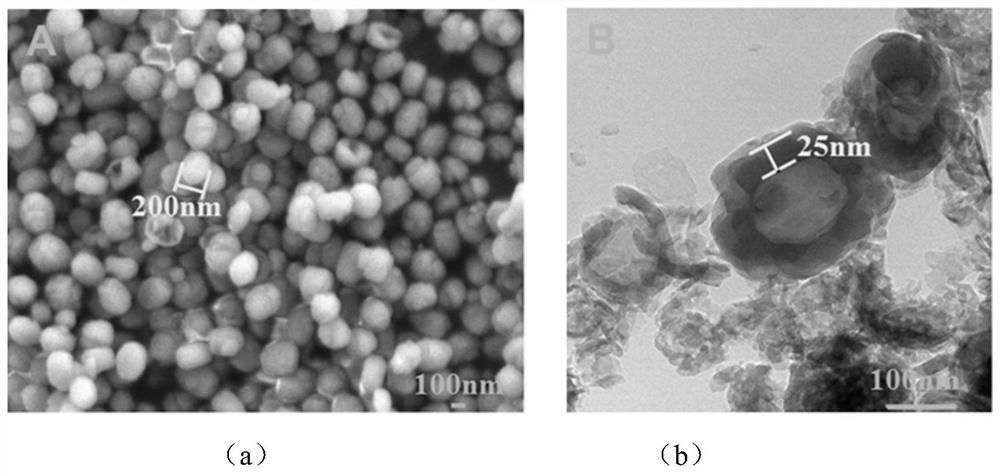

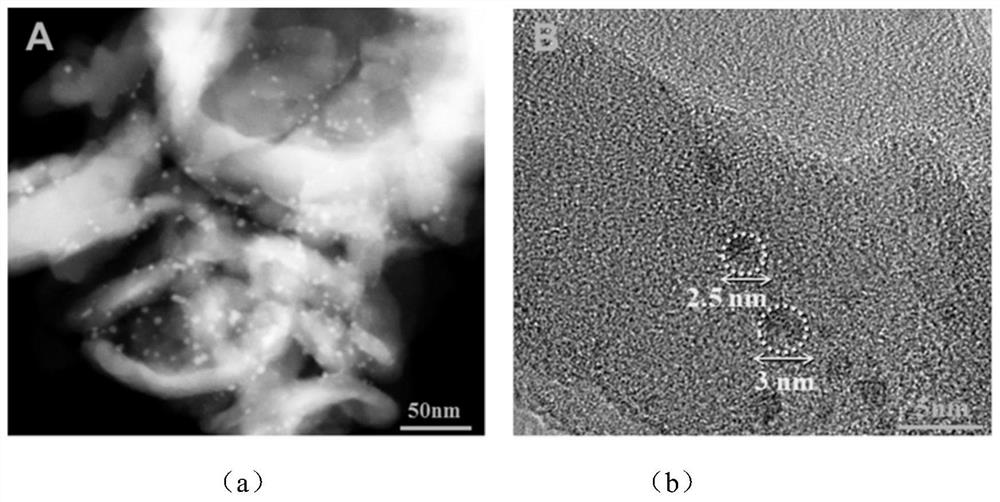

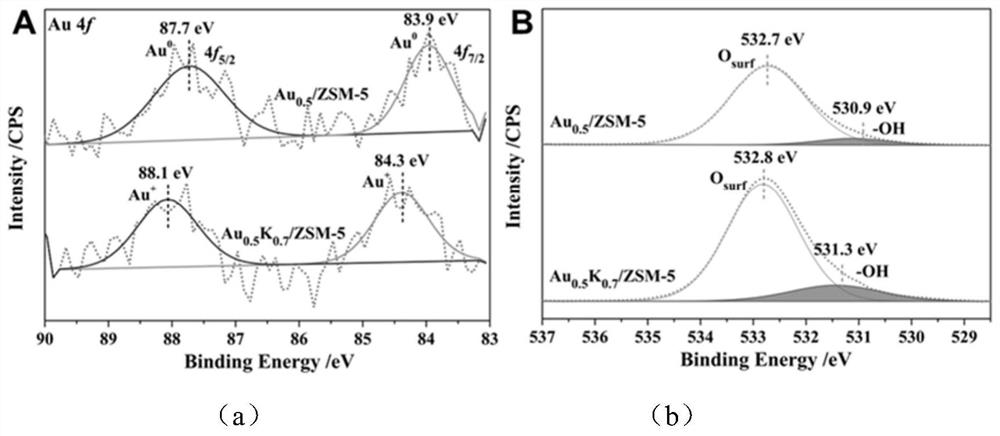

[0037] Mix 12g tetrapropylammonium hydroxide (TPAOH) solution with 12.5g tetraethylorthosilicate (TEOS), heat to 80°C and stir at 700rpm for 24h, after cooling to room temperature, add dropwise under vigorous stirring From NaOH (0.24g), Al (NO 3 ) 3 9H 2 O (0.45g) and deionized water (4mL) mixed solution. After homogenization, it was transferred to a Teflon reactor, crystallized at 170°C for 24h, then centrifuged at 9000rpm, washed with deionized water, dried at 100°C overnight, and calcined in a muffle furnace at 550°C for 11h. The above product was dissolved in 0.2mol / L NaOH solution (35mL·g -1 Zeolite) was subjected to alkaline leaching, stirred at 650rpm for 10h, centrifuged at 9000rpm and dried at room temperature, and the obtained solid was the hollow-structured hierarch...

Embodiment 2

[0043] Embodiment 2 single metal Au supported catalytic material Au 0.5 / ZSM-5 Catalytic Degradation Activity and Stability Test of Acetone

[0044] The catalytic reaction was carried out in a fixed bed, the catalyst obtained in Example 1 was pressed into tablets, sieved (40-60 mesh), and 0.3 mL of the sieved catalytic material was weighed, activated at 200 ° C for 2 h, and acetone (acetone) was used as Probe gas, the concentration of reactants is controlled at 1500ppm, and the reaction space velocity is 60,000h -1 , the oxygen concentration is 20%, respectively test the catalytic activity of the catalyst at 140°C, 160°C, 180°C, 200°C, 220°C, 240°C, 260°C, 280°C, 300°C, the reaction products are passed through gas chromatography and On-line mass spectrometry monitoring analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com