Continuous synthesis method and reaction device of boron trifluoride complex

A technology of boron trifluoride and synthesis method, applied in chemistry/physics/physicochemistry reactor, chemistry/physics/physicochemistry fixed reactor, chemical instrument and method, etc., capable of solving intermittent single batch reaction with long time , low synthesis efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a continuous synthesis method of boron trifluoride complex, comprising the following steps:

[0026] In the continuous flow reactor, the organic matter containing the lone pair of electrons and boron trifluoride are subjected to a complex reaction to obtain the boron trifluoride complex. The continuous flow reactor is a microchannel reactor, a tubular reaction One or more of mixers, stack mixers and static mixers.

[0027] In the present invention, unless otherwise specified, the raw materials used are commercially available products well known to those skilled in the art.

[0028] In the present invention, the organic compound containing a lone pair of electrons preferably includes any one of ether compounds, ester compounds, organic acids, furan compounds and alcohol compounds. In the present invention, the ether compound is preferably methyl ether, diethyl ether, propyl ether or butyl ether, the ester compound is preferably methyl formate or e...

Embodiment 1

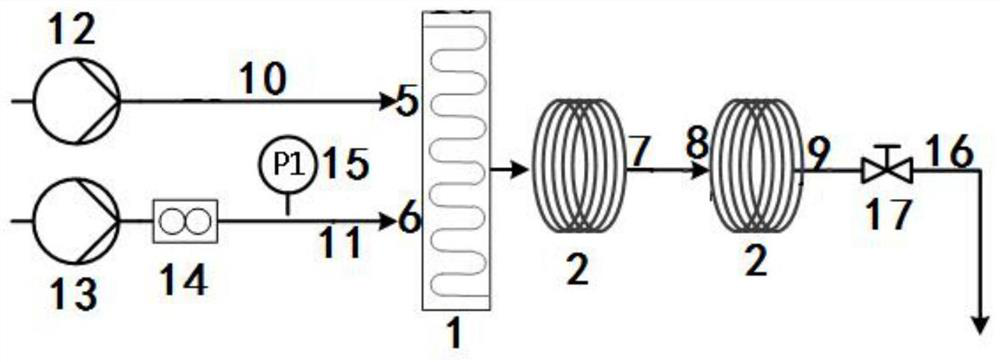

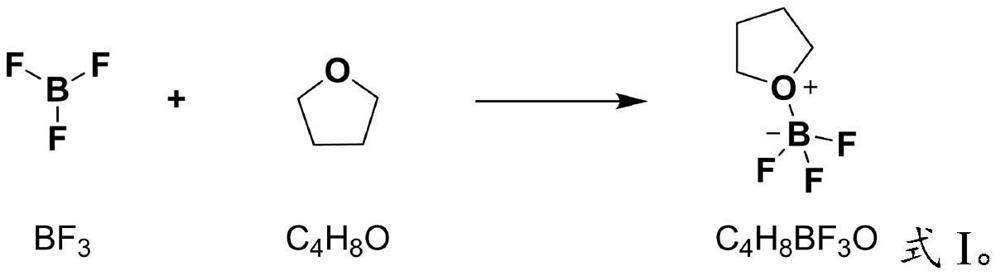

[0058] The device for preparing boron trifluoride tetrahydrofuran complex is as figure 1 Shown, the raw material parameter and reaction parameter of preparing boron trifluoride tetrahydrofuran complex compound are as shown in table 1, and concrete reaction equation is shown in formula I:

[0059]

[0060] The specific operation process is: the anhydrous tetrahydrofuran whose feed rate is controlled by the feed pump is transported from the liquid feed pipe to the liquid raw material inlet of the continuous reaction unit composed of a microchannel reactor and a tubular reactor in series, and the anhydrous tetrahydrofuran is Add the boron trifluoride gas in the gas storage tank to the microchannel reactor through the gas raw material feeding pipeline, the flow rate is controlled by the flow meter set on the gas raw material feeding pipeline, and the flow rate is controlled by the flow meter set on the gas raw material feeding pipeline The pressure is controlled by a pressure gau...

Embodiment 2

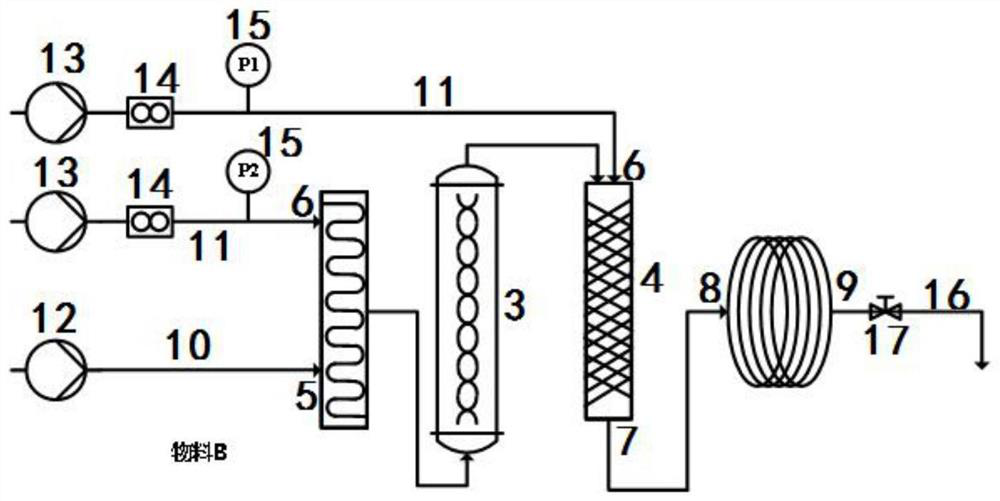

[0068] The device for preparing boron trifluoride etherate complex is as figure 2 Shown, the raw material parameter and the reaction parameter of preparing boron trifluoride diethyl ether complex are as shown in table 2, and concrete reaction equation is shown in formula II:

[0069]

[0070] The specific operation process is: the anhydrous diethyl ether whose feed rate is controlled by the feed pump is transported from the liquid feed pipe to the liquid raw material inlet of the continuous reaction unit composed of a microchannel reactor and a tubular reactor in series, and the anhydrous diethyl ether Add the boron trifluoride gas in the gas storage tank to the microchannel reactor through the gas raw material feeding pipeline, the flow rate is controlled by the flow meter set on the gas raw material feeding pipeline, and the flow rate is controlled by the flow meter set on the gas raw material feeding pipeline The pressure is controlled by a pressure gauge, which is sent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com