Polyarylether compound and preparation method thereof, polyarylether-hydrogel composite porous membrane and preparation method and application thereof

A technology of polyarylether and compound, which is applied in the field of polyarylether-hydrogel composite porous membrane and its preparation, can solve the problems of low operating cost and weak ion selectivity, and achieve low cost, high practical value, and ion selectivity good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention provides the preparation method of polyarylether compound described in above-mentioned technical scheme, comprises the following steps:

[0051] Mix the first monomer, the second monomer, the third monomer, an organic solvent, a catalyst, and a water-carrying agent, heat to the reflux temperature of the water-carrying agent to perform water removal treatment, and then increase the temperature to carry out polycondensation reaction to obtain a formula I Or the polyarylether compound of structure shown in formula II;

[0052] The first monomer is

[0053] The second monomer is

[0054] The third monomer is The X is a halogen group.

[0055]In the present invention, the third monomer is p-halogenated diphenyl sulfone / ketone monomer, wherein the halogen group is preferably -F or -Cl. In the present invention, there is no special limitation on the molar ratio of the first monomer to the second monomer, any molar ratio is acceptable, and the...

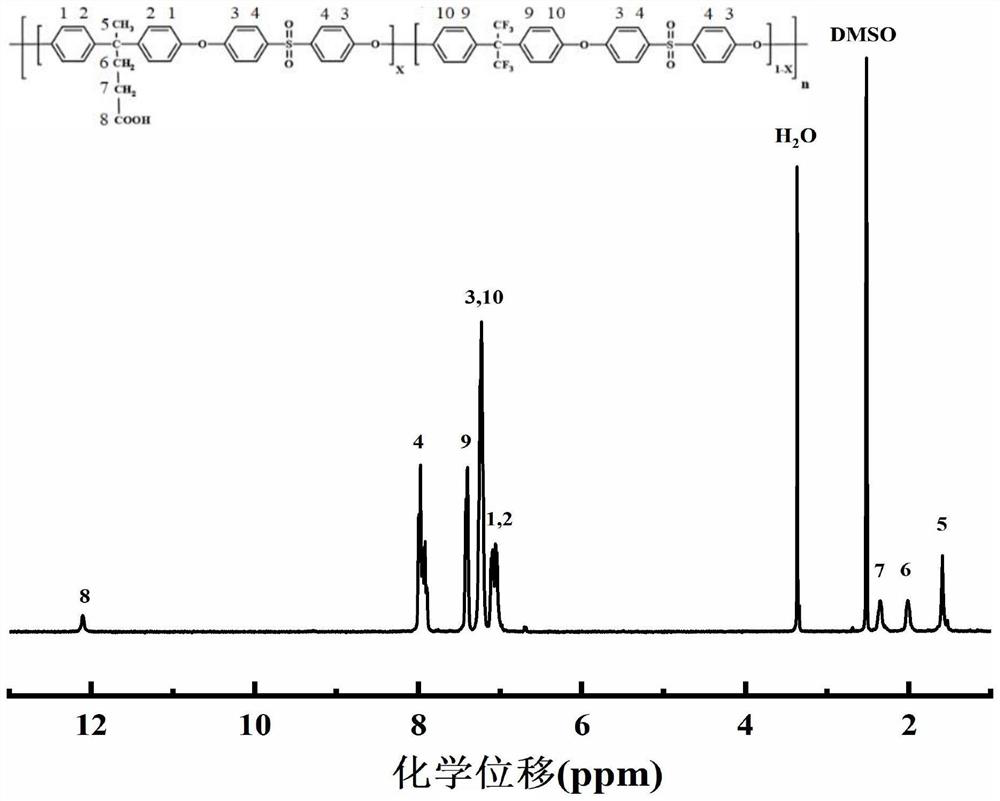

Embodiment 1

[0077]Under the condition of anhydrous and argon protection, add 20.0mmol (5.09g) of 4,4'-difluorodiphenylsulfone and 8.0mmol of 4,4-bis(4-hydroxyphenyl)pentanoic acid into a 100mL three-necked flask (2.29g), 2,2'-bis(4-hydroxyphenyl)-hexafluoropropane 12.0mmol (4.04g), 4.0g potassium carbonate, 14mL toluene and 36mL sulfolane, the resulting mixed system was heated to Reflux (145°C) for 4 hours to allow the toluene to fully remove the water generated in the system; then heat the obtained system to 175°C for 6 hours, and the viscosity of the system will not change; pour the obtained product system into deionized water to precipitate solid materials. After the solid material is pulverized, it is washed with boiling water for 3 times, and then with ethanol for 3 times, and then dried in vacuum at 80°C to a constant weight to obtain a white solid, which is a polyarylether compound. The logarithmic viscosity is 0.53, the number average molecular weight is 65kDa, and the dispersibil...

Embodiment 2

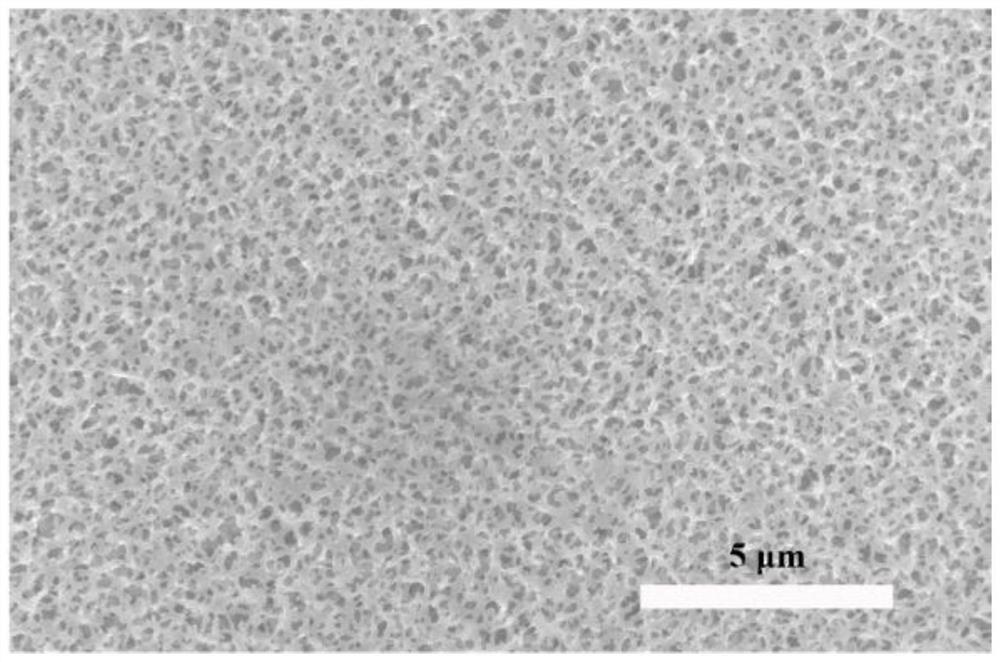

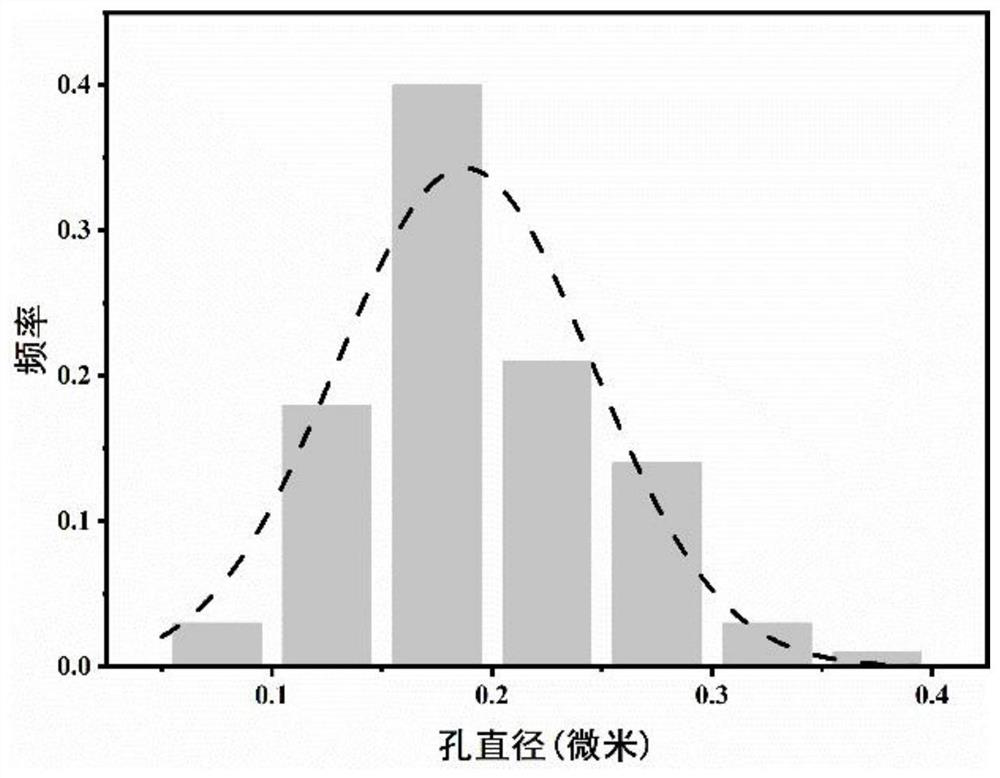

[0079] Mix 1 g of the polyarylether compound prepared in Example 1, 1 g of polyvinylpyrrolidone-K30, and 3.45 mL of N-methylpyrrolidone, and stir for 10 h at room temperature (25° C.) under airtight conditions to obtain a clear and transparent viscous liquid. After cloth filtration, stand for degassing for 12 hours to obtain the casting solution;

[0080] Cast the film casting solution on the surface of a smooth and flat 10cm×10cm glass plate, scrape it into a thin and uniform liquid film with a glass scraper, expose it to the air for 2 minutes, and slowly immerse the liquid film and glass plate in deionization In water, solvent exchange occurs, the water is changed once every 8 hours, and the water is changed three times in total. The obtained film is removed and dried at 60°C for 12 hours to obtain a polyarylene ether porous film with a thickness of 47 μm, a pore size of 180 nm, and a porosity of 42.9%. ;

[0081] Mix 2.5g of 2-acrylamide-2-methylpropanesulfonic acid, 0.025...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com