Preparation process of multilayer metal composite belt

A multi-layer metal and preparation process technology, applied in metal rolling and other directions, can solve the problems of reducing production costs, complex processes, and high equipment costs, and achieve the effects of easy control and operation, good compounding effect, and high compounding rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

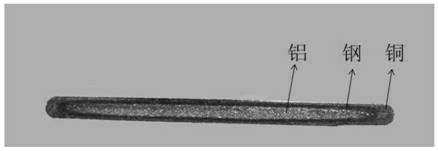

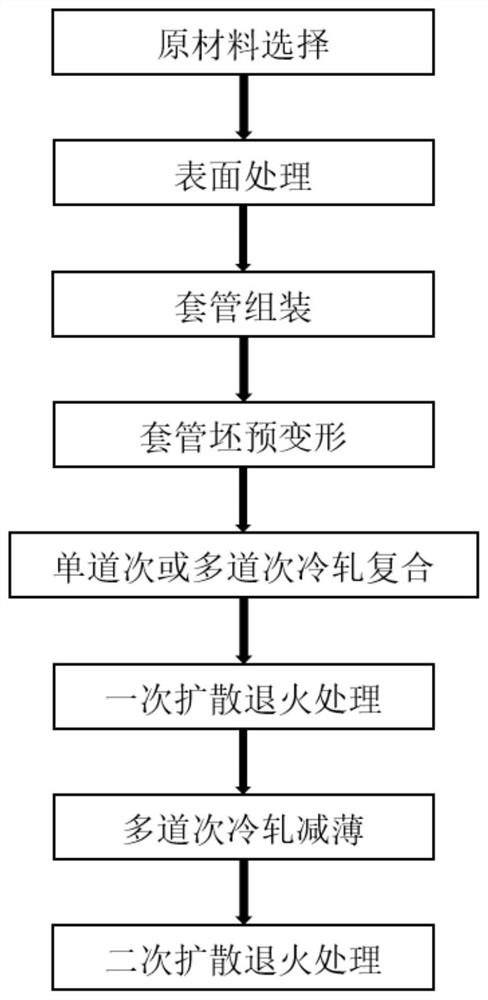

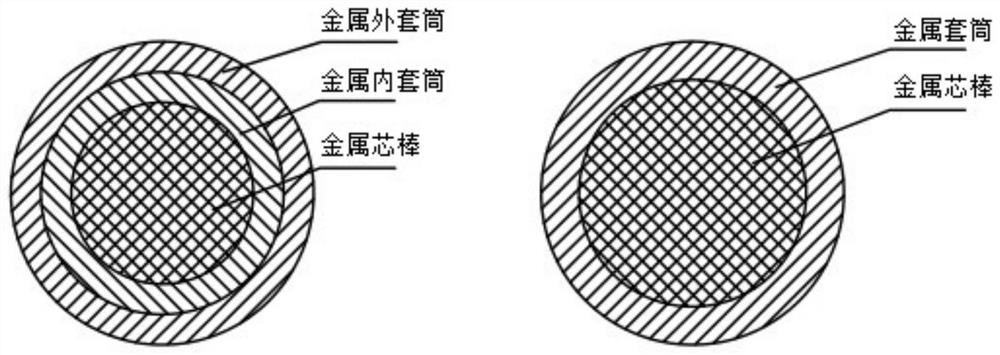

[0043] according to figure 1 The process flow diagram for preparing a copper / steel / aluminum metal composite strip with a thickness of 0.1mm comprises the following steps:

[0044] S1: Selection of raw materials: T2 copper pipe with an outer diameter of 20mm and a wall thickness of 2mm, a Q235 steel pipe with an outer diameter of 15mm and a wall thickness of 1mm, and a 1060 aluminum rod with a diameter of 12mm are selected as raw materials, and the T2 copper pipe, Q235 steel pipe, and 1060 aluminum rod are respectively Put it in a heating furnace with a temperature of 600°C, 1150°C, 400°C, and a holding time of 2h, 0.5h, and 2h for annealing treatment to remove the work hardening of raw materials;

[0045] S2: Surface treatment: Use different grades of sandpaper 400#, 800#, 1200#, 800#, 240#, 60# to derust and roughen the inner and outer surfaces of T2 copper pipes, Q235 steel pipes, and 1060 aluminum rods ; Use a high-frequency ultrasonic instrument to degrease, set the ultr...

Embodiment 2

[0053] according to figure 1 The process flow chart for preparing a titanium / magnesium / aluminum metal composite strip with a thickness of 0.1mm comprises the following steps:

[0054] S1: Selection of raw materials: TA1 titanium tube with an outer diameter of 20mm and a wall thickness of 2mm, an AZ31B magnesium alloy tube with an outer diameter of 15mm and a wall thickness of 3mm, and a 1060 aluminum rod with a diameter of 8mm are selected as raw materials, and the TA1 titanium tube, AZ31B magnesium alloy tube, 1060 aluminum rods were annealed in heating furnaces with temperatures of 500°C, 400°C, and 400°C, and holding times of 1h, 1h, and 2h to remove raw materials for work hardening;

[0055] S2: Surface treatment: Use different grades of sandpaper 400#, 800#, 1200#, 800#, 240#, 60# to derust and roughen the inner and outer surfaces of TA1 titanium tubes, AZ31B magnesium alloy tubes, and 1060 aluminum rods. Chemical treatment; use a high-frequency ultrasonic instrument to...

Embodiment 3

[0063] according to figure 1 Described process flow chart, preparation a kind of thickness is the copper / steel metal composite strip of 0.1mm, comprises the following steps:

[0064] S1: Selection of raw materials: Select T2 copper tube with outer diameter of 22, wall thickness of 3mm and Q235 steel rod with diameter of 15mm as raw materials, place T2 copper tube and Q235 steel rod at temperatures of 600°C and 1150°C respectively, and hold for 2 hours , 0.5h, annealing treatment in the heating furnace to remove the work hardening of raw materials;

[0065] S2: Surface treatment: Use different grades of sandpaper 400#, 800#, 1200#, 800#, 240#, 60# to derust and roughen the inner and outer surfaces of T2 copper pipes and the surface of Q235 steel rods; use high-frequency ultrasonic Degrease with the instrument, set the ultrasonic frequency to 50-150kHz, and the temperature of the cleaning solution to be 20-35°C; use a cooling fan to dry the surface of the T2 copper tube and Q2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com