Disinfection method and device for food outer packaging based on combination of jet flow and coating

A disinfection device and outer packaging technology, applied in the direction of packaging sterilization, etc., to reduce the amount of application, avoid food quality damage, and prevent residual pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

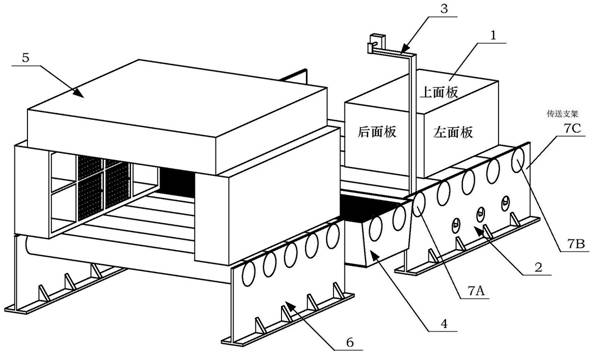

[0112] Example 1 is Figure 4 , Figure 4B A low-temperature plasma jet food packaging straight-through sterilization device shown is composed of a packaging box transmission unit 2, an image and positioning acquisition unit 3, a chemical disinfectant coating unit 4, and an atmospheric pressure low-temperature plasma jet unit 5 constitute. The packing case transmission unit 2 selects the motor-driven roller to drive the belt transmission mode to transport the packing case, and the coating unit 4 of the chemical disinfectant selects the felt roller for use. Embodiment 1 adopts the disinfection method of low-temperature plasma jet combined with brushing chemical agent on the bottom surface, that is, uses the felt roller to brush the disinfectant on the lower part, realizes the disinfection on the bottom surface of the box, and kills the top surface and side of the rack cavity Multiple atmospheric-pressure low-temperature plasma jet integrated modules 5D are installed, and each...

Embodiment 2

[0116] The difference between embodiment 2 and embodiment 1 is:

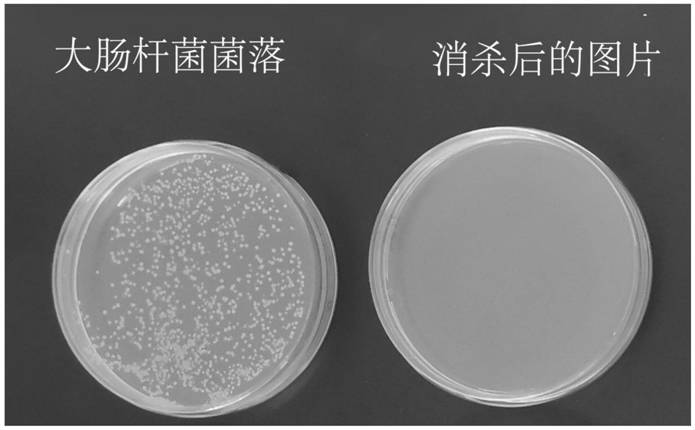

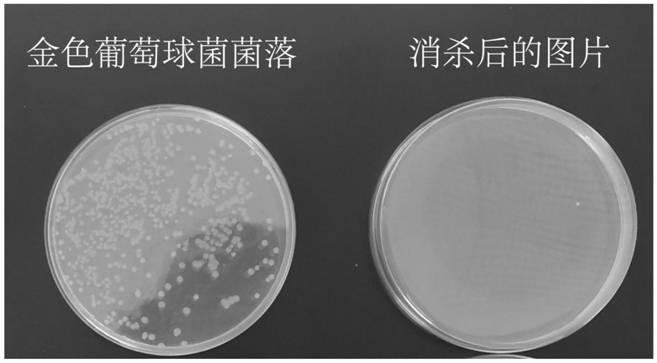

[0117] The jet head adopts a ring-ring dielectric barrier structure, and the material of the dielectric barrier is a quartz tube (outer diameter 5mm, inner diameter 3mm). The high-voltage electrode and the low-voltage electrode are both made of perforated copper plates. The copper plate passes through and is fixed in the fluidic module. Each jet module contains 25 jet heads (5×5), and the distance between each jet head is 3mm. Using a high-voltage pulse power supply as the power supply, using argon as the carrier gas, the single-tube argon gas flow rate is 4L / min, the high-voltage electrode voltage is 20kV, the output power frequency is 10kHz, and the plasma jet length can be achieved at 30mm. After the cold chain food of different shapes passes through the sterilization equipment, the sterilization efficiency of pathogenic microorganisms can reach 100%.

Embodiment 3

[0119] Example 1 is Image 6 Shown is a low-temperature plasma jet food outer packaging folding type sterilization device, which consists of a packaging box transmission unit 2, an image and positioning acquisition unit 3, a chemical disinfectant coating unit 4, and an atmospheric pressure low-temperature plasma jet unit 5 , an ozone decomposition catalytic unit 9, a Y-axis atmospheric pressure low-temperature plasma jet unit 10, a gas purification unit 11 and a Y-axis conveyor belt transmission unit 12. The packing case transmission unit 2 selects the motor-driven roller to drive the belt transmission mode to transport the packing case, and the coating unit 4 of the chemical disinfectant selects the felt roller for use. Embodiment 3 adopts the sterilization method of low-temperature plasma jet combined with brushing chemical agent on the bottom surface, that is, uses the felt roller to brush the disinfectant on the lower part, realizes the sterilization on the bottom surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com