Aromatic diamine monomer containing cyano structure, preparation method of aromatic diamine monomer, polyimide, polyimide film, and preparation method and application of polyimide film

A technology of polyimide film and aromatic diamine, which is applied in the field of polyimide, can solve the problem of reducing the dielectric constant of polyimide, the complex synthesis route of new diamine monomer, the thermal stability of polyimide and the Problems such as mechanical properties need to be improved to achieve good thermal stability and mechanical properties, suitable for large-scale production, and improve processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a preparation method for the cyano-containing aromatic diamine monomer described in the technical solution, comprising the following steps:

[0046] (1) mixing a compound having a structure shown in formula I with a compound having a structure shown in formula II, a basic compound and a polar solvent, and performing a nucleophilic substitution reaction to obtain an intermediate having a structure shown in formula III;

[0047]

[0048] R in the formulas I, II and III 1 , R 2 is independently cyano;

[0049] (2) performing a reduction reaction on an intermediate having a structure shown in formula III to obtain an aromatic diamine monomer having a cyano group structure having a structure shown in formula IV;

[0050]

[0051] R in the formula IV 1 , R 2 is independently cyano.

[0052] In the present invention, unless otherwise specified, the raw materials used are conventional commercially available products in this field. ...

Embodiment 1

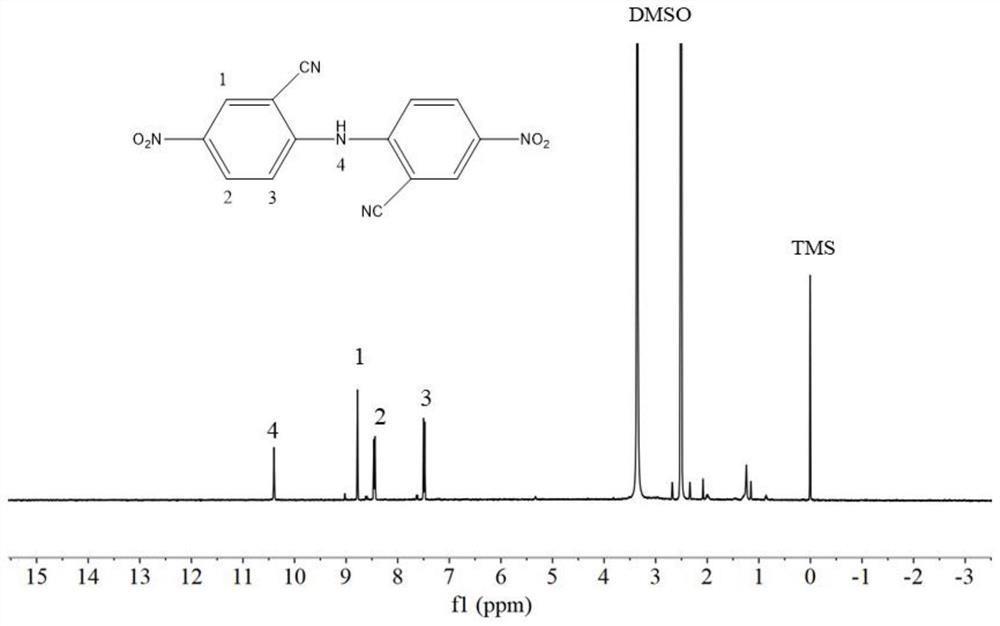

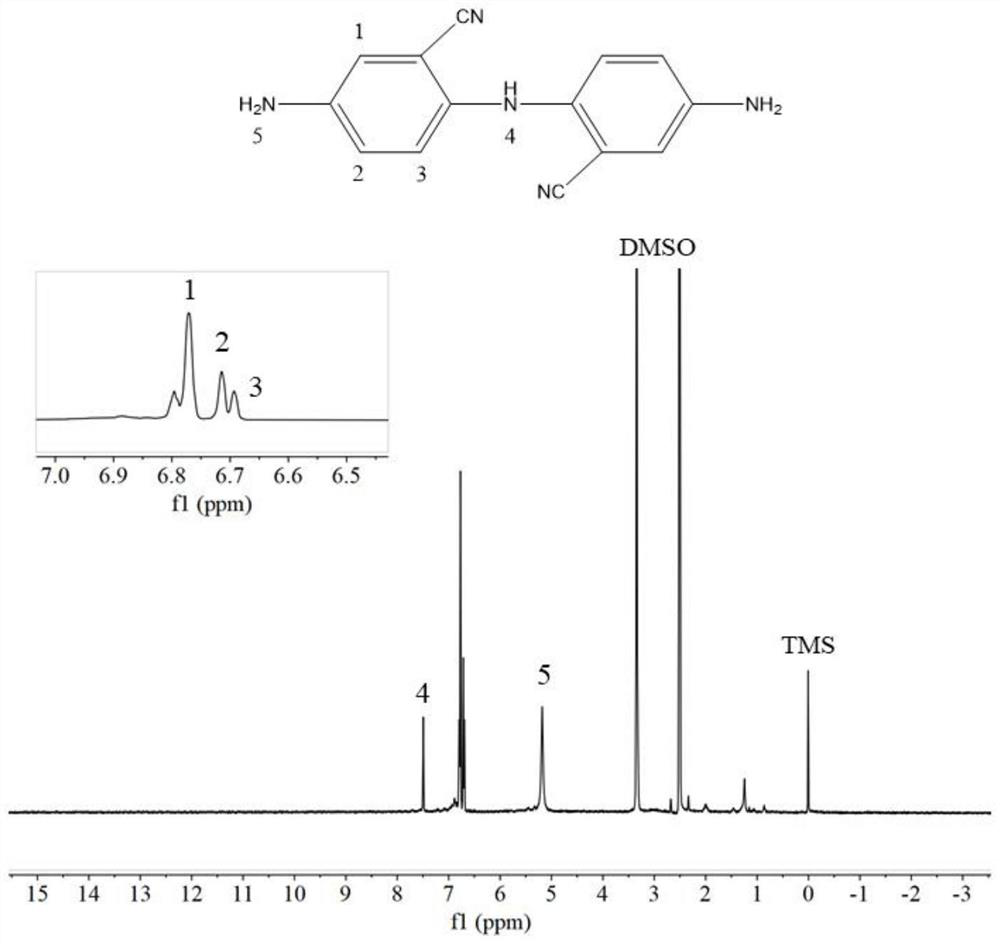

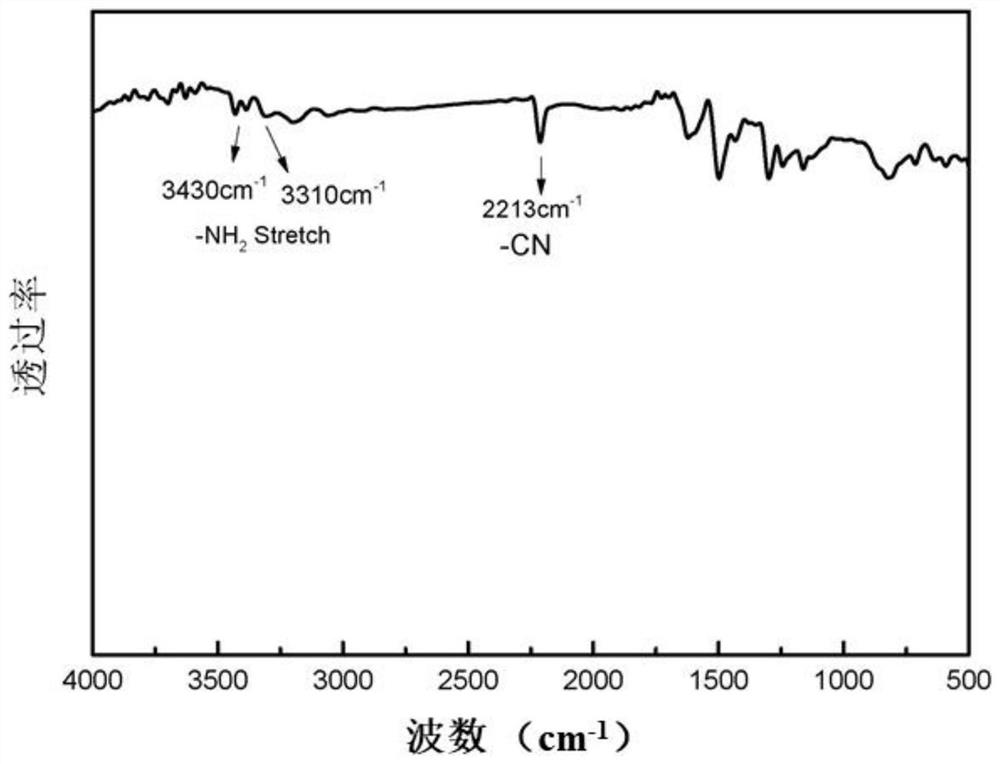

[0125] Preparation of aromatic diamine monomer bis(2-cyano-4-aminophenyl)amine containing cyano group structure

[0126] (1) 2.447g of 2-cyano-4-nitroaniline, 2.738g of 2-chloro-5-nitrobenzonitrile and 2.073g of anhydrous potassium carbonate and 30mL of DMAC polar solvent were added to the container Mix in a 250mL round-bottomed three-necked flask with a nitrogen inlet, magnetic stirring and condenser, stir and heat to 160°C for 24 hours, after the reaction, cool the system to 110°C, mix it with 200mL deionized water, and filter to obtain The reddish-brown solid was washed successively with deionized water and ethanol for 2 to 3 times, and dried in a vacuum oven at 80° C. for 12 hours to obtain 3.063 g of reddish-brown solid powder, which was then recrystallized with acetonitrile to obtain 2.389 g of brown solid powder (2 -cyano-4-nitrophenyl)amine intermediate, the productive rate is 75~80%; wherein said 2-cyano-4-nitroaniline, 2-chloro-5-nitrobenzonitrile and carbonic acid ...

Embodiment 2

[0136] The bis(2-cyano-4-aminophenyl)amine prepared in Example 1 was used as a diamine monomer to prepare a cyano-containing polyimide film PI-1.

[0137] (1) Di(2-cyano-4-aminophenyl)amine (0.1245g, 0.5mmol) and pyromellitic dianhydride (0.1091g, 0.5mmol) were dissolved in 2.1024mL of N,N-dimethyl Add acetamide (DMAC) into the reactor equipped with mechanical stirring, nitrogen gas inlet and outlet and thermometer, feed nitrogen gas, carry out polycondensation reaction for 5-8 hours under the condition of stirring at room temperature, put it in a vacuum drying oven to remove air bubbles for 3 minutes, and obtain A homogeneous viscous polyamic acid solution with a mass concentration of 10%; wherein, the cyano-containing aromatic diamine monomer (two (2-cyano-4-aminophenyl) amine) and the dianhydride monomer (Pyromellitic dianhydride) The ratio of the amount of substance is 1:1;

[0138] (2) Cast the polyamic acid solution obtained in the step (1) onto a clean and dry glass pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com