A method for preparing iron tannate coordination modified molybdenum disulfide hydrogel dressing

A technology of molybdenum disulfide and tannic acid, which is applied in molybdenum sulfide, pharmaceutical formulations, bandages, etc., can solve problems such as failure to function, difficult repair, tissue necrosis, etc., and achieve good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a method for preparing molybdenum disulfide hydrogel dressing modified with iron tannate coordination, comprising the following steps:

[0034] Step 1, mixing sodium molybdate, thiourea and water to obtain a molybdenum source solution; the quality of the thiourea is 1.26 times the quality of sodium molybdate, and the quality of the water is 62.02 times the quality of sodium molybdate;

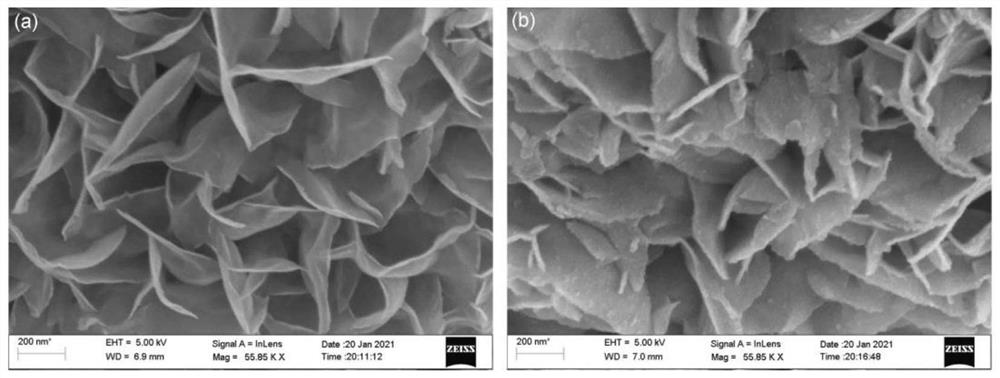

[0035] Step 2: Under the temperature condition of 220°C, react the molybdenum source solution described in step 1 for 24 hours, cool it naturally to room temperature, wash with deionized water and ethanol, centrifuge, remove the supernatant, and dry the precipitate at 60°C Dry to constant weight to obtain molybdenum disulfide nanosheets;

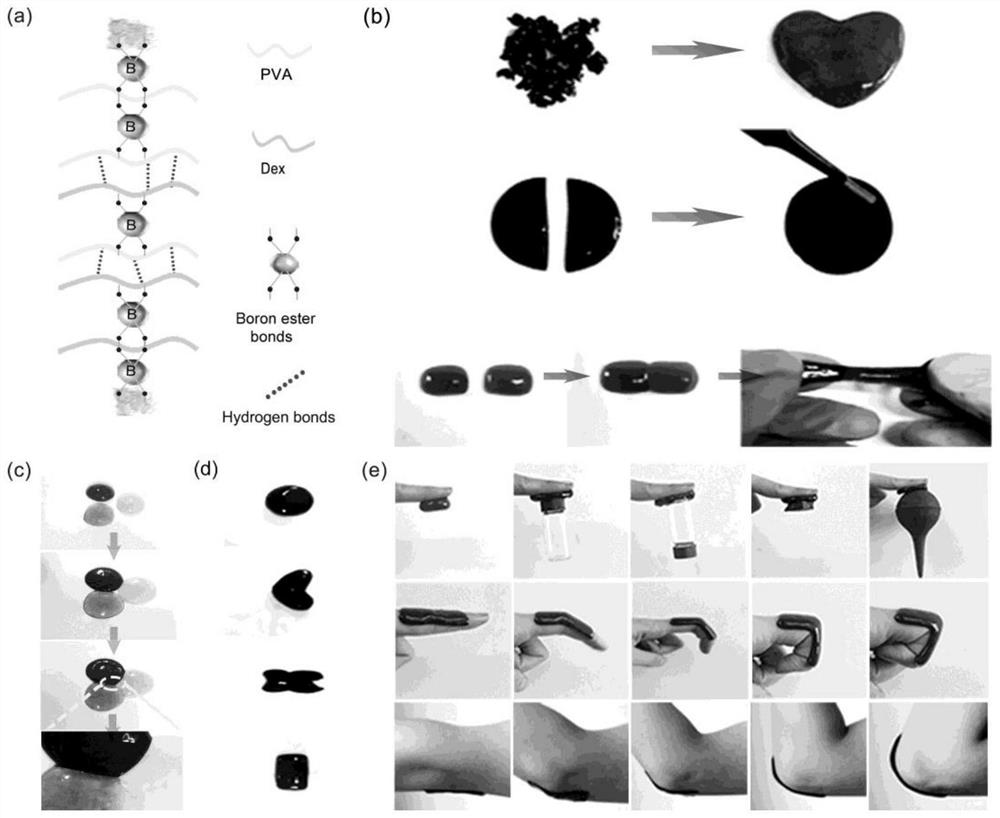

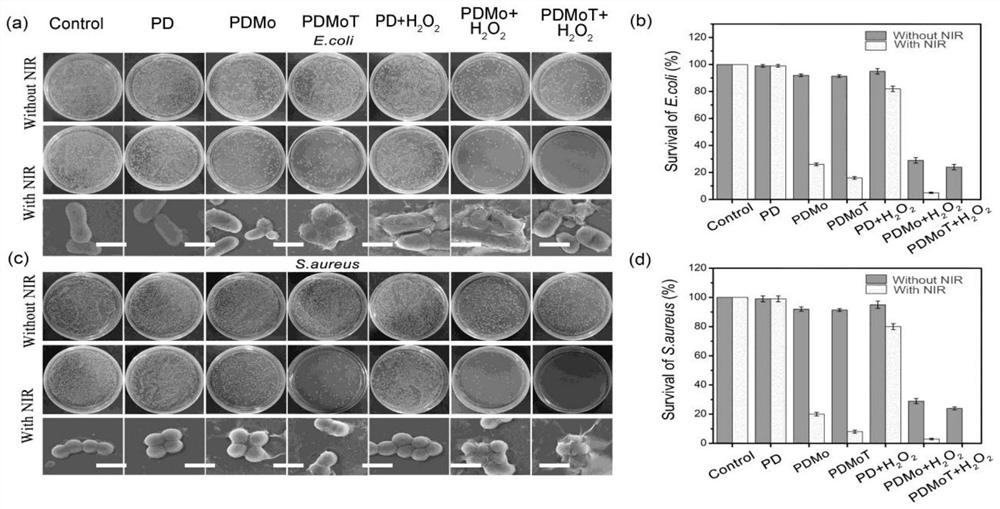

[0036] Step 3. Under ultrasonic conditions, the molybdenum disulfide nanosheets described in step 2 are dispersed in deionized water to obtain a molybdenum disulfide nanosheet dispersion system, and the molybdenum disulfide nan...

Embodiment 2

[0062] This embodiment provides a method for preparing molybdenum disulfide hydrogel dressing modified with iron tannate coordination, comprising the following steps:

[0063] Step 1, mixing sodium molybdate, thiourea and water to obtain a molybdenum source solution; the quality of the thiourea is 1.26 times the quality of sodium molybdate, and the quality of the water is 62.02 times the quality of sodium molybdate;

[0064] Step 2. Under the temperature condition of 220°C, react the molybdenum source solution described in step 1 for 24 hours, cool it naturally to room temperature, wash with deionized water and ethanol, centrifuge, remove the supernatant, and dry the precipitate at 50°C Dry to constant weight to obtain molybdenum disulfide nanosheets;

[0065] Step 3. Under ultrasonic conditions, the molybdenum disulfide nanosheets described in step 2 are dispersed in deionized water to obtain a molybdenum disulfide nanosheet dispersion system, and the molybdenum disulfide nan...

Embodiment 3

[0073] This embodiment provides a method for preparing molybdenum disulfide hydrogel dressing modified with iron tannate coordination, comprising the following steps:

[0074] Step 1, mixing sodium molybdate, thiourea and water to obtain a molybdenum source solution; the quality of the thiourea is 1.26 times the quality of sodium molybdate, and the quality of the water is 92.88 times the quality of sodium molybdate;

[0075] Step 2. Under the temperature condition of 220°C, react the molybdenum source solution described in step 1 for 24 hours, cool it down to room temperature naturally, wash with deionized water and ethanol, centrifuge, remove the supernatant, and dry the precipitate at 70°C Dry to constant weight to obtain molybdenum disulfide nanosheets;

[0076] Step 3. Under ultrasonic conditions, the molybdenum disulfide nanosheets described in step 2 are dispersed in deionized water to obtain a molybdenum disulfide nanosheet dispersion system, and the molybdenum disulfid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com