Anion-cation doped P2 type sodium ion battery positive electrode material

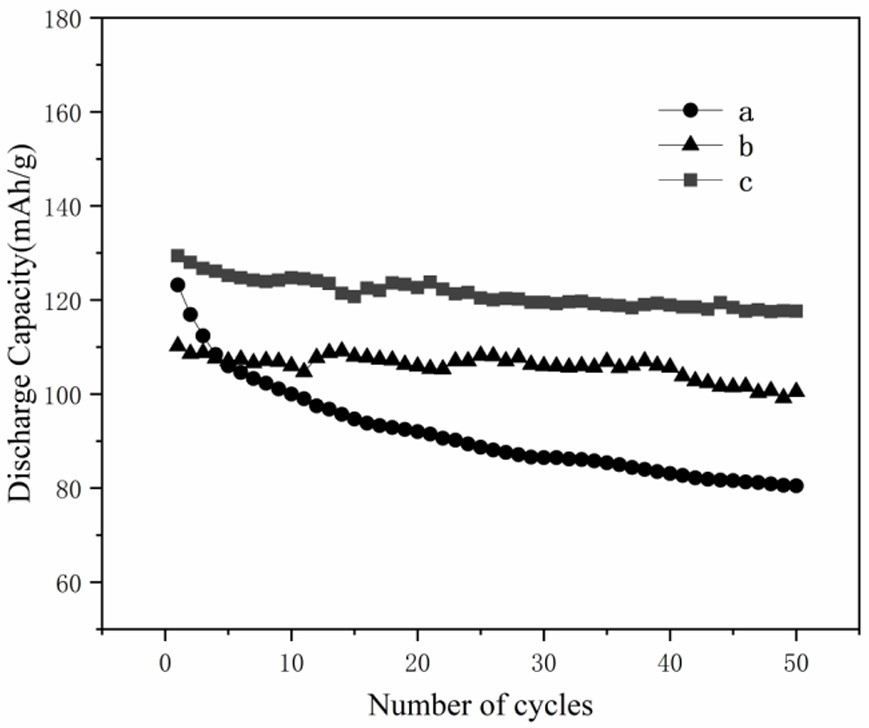

A sodium ion battery, anion and cation technology, applied in the direction of battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of reducing the overall performance of the battery, poor material cycle stability, and low reversible specific capacity, and achieve good industrial application prospects. Excellent electrochemical performance, the effect of improving specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Another typical embodiment of the present invention provides a method for preparing the anode and cation doped P2 type sodium ion battery cathode material, which includes the following steps.

[0030] Step 1, according to the chemical formula Na 0.67 Cu x mn 1-x o 2-y f y In the molar ratio of Mn, Cu and F elements, weigh manganese salt, copper salt and sodium fluoride and dissolve them in deionized water, then add sodium salt, stir and dissolve, and prepare mixed metal salt solution, and citric acid solution is used as complexing agent.

[0031] Preferably, the total molar concentration of metal ions is 1-3 mol / L; a citric acid solution with a mass concentration of 2%-20% is prepared as a complexing agent.

[0032]Preferably, the manganese salt described in step 1 is one or more of manganese sulfate, manganese nitrate, manganese acetate or manganese chloride; the copper salt is one or more of copper sulfate, copper nitrate or copper chloride multiple, and the sodi...

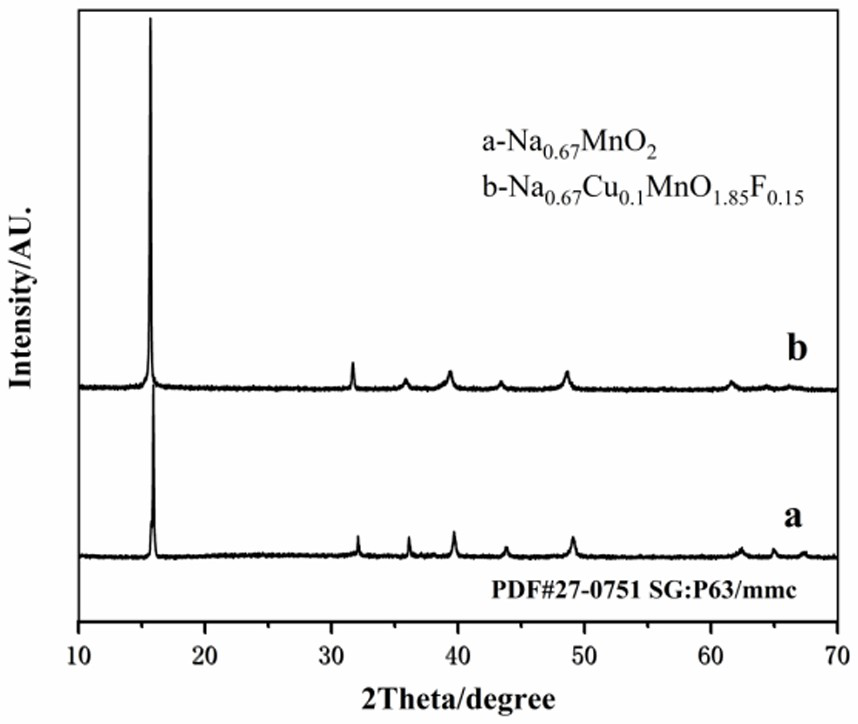

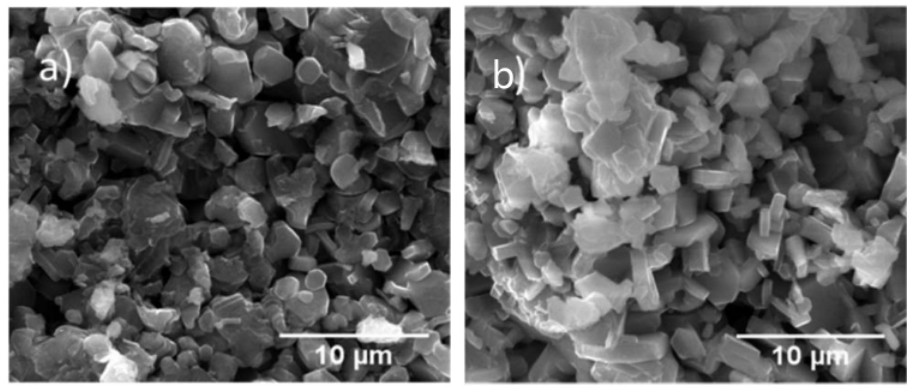

Embodiment 1

[0053] (1) According to the synthesis of 2g of Na 0.67 Cu 0.1 mn 0.9 o 1.9 f 0.1 The molar ratio of Na, Cu, Mn and F elements in Na, Cu, Mn and F elements were weighed and dissolved in deionized water with sodium acetate (5% excess), copper acetate, manganese acetate and sodium fluoride, so that the total concentration of metal ions was 2mol / L, and kept stirring until the metal salt solution dissolves. Prepare a citric acid solution with a mass concentration of 10%, slowly add the metal salt solution into the citric acid solution, adjust the pH value of the mixed solution to 9 with ammonia water, stir and evaporate to dryness at 85°C to obtain a gel substance.

[0054] (2) Dry the gel obtained in step (1) at 115°C, crush it, raise the temperature to 250°C at a rate of 2°C / min in an air atmosphere, keep it for 3 hours, and then continue to heat it up to 550°C for 5 hours. Then increase the temperature to 850°C at a rate of 2°C / min, keep it warm for 11 hours, and cool to ro...

Embodiment 2

[0056] (1) According to the synthesis of 2g of Na 0.67 Cu 0.1 mn 0.9 o 1.85 f 0.15 The molar ratio of Na, Cu, Mn and F elements in the medium is weighed and dissolved in deionized water with sodium nitrate (5% excess), copper nitrate, manganese nitrate and sodium fluoride, so that the total concentration of metal ions is 2mol / L, and kept stirring until the metal salt solution dissolves. Prepare a citric acid solution with a mass concentration of 15%, slowly add the metal salt solution into the citric acid solution, adjust the pH value of the mixed solution to 10 with ammonia water, stir and evaporate to dryness at 90°C to obtain a gel substance.

[0057] (2) Dry the gel obtained in step (1) at 100°C, break it up, heat it up to 300°C at a rate of 3°C / min in an air atmosphere, keep it warm for 3.5 hours, and then continue to heat it up to 600°C and keep it warm for 5.5 hours . Then increase the temperature to 900°C at a rate of 3°C / min, keep it warm for 12 hours, and cool ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Initial discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com