Catalyst for catalyzing hydrolysis of ammonia borane to produce hydrogen as well as preparation method and application of catalyst

A hydrolysis hydrogen production and catalyst technology, applied in the field of hydrogen storage materials, can solve the problems of high cost and low catalytic activity, and achieve the effects of easy operation, reduced synthesis cost, and simple and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Polyhedral doped P-Cu-Co with different phosphorus content 3 o 4 Preparation of @C catalyst.

[0036] (1) Weigh 0.87 g Co(NO 3 ) 2 ·6H 2 O and 0.26 gCu(acac) 2 Add 40 mL of anhydrous methanol, stir to dissolve until a light red clear solution is obtained; weigh 1.31 g of 2-methylimidazole and dissolve it in 40 mL of anhydrous methanol to obtain a colorless and clear solution, stir and disperse for 30 minutes, and dissolve 2-methylimidazole The methanol solution of imidazole was quickly poured into Co(NO 3 ) 2 ·6H 2 O and Cu(acac) 2 In the methanol solution, keep the stirring condition unchanged, after stirring for 24 h, Cu(acac) 2 @ZIF-67 purple precursor solution. Cu(acac) 2 The @ZIF-67 precursor solution was centrifuged at a speed of 10000r / min, and washed with anhydrous methanol. After repeated centrifugation and washing four times, the collected purple solid was vacuum-dried at 50°C for 12h to obtain Cu( acac) 2 @ZIF-67.

[0037] (2) Weigh 150mg Cu(aca...

Embodiment 2

[0040] Polyhedral doped P-Cu-Co with different phosphorus content 3 o 4 Preparation of @C catalyst.

[0041] The difference with Example 1 is only to change the quality of sodium hypophosphite in step (2) to 70 mg or 210 mg, and the samples are recorded as P1-Cu-Co 3 o 4 @C、P3-Cu-Co 3 o 4 @C.

Embodiment 3

[0043] Comparative polyhedral Cu-Co 3 o 4 Preparation of @C catalyst.

[0044] The difference from Example 1 is only that the sintering process of the sample and sodium hypophosphite in the step (2) is removed.

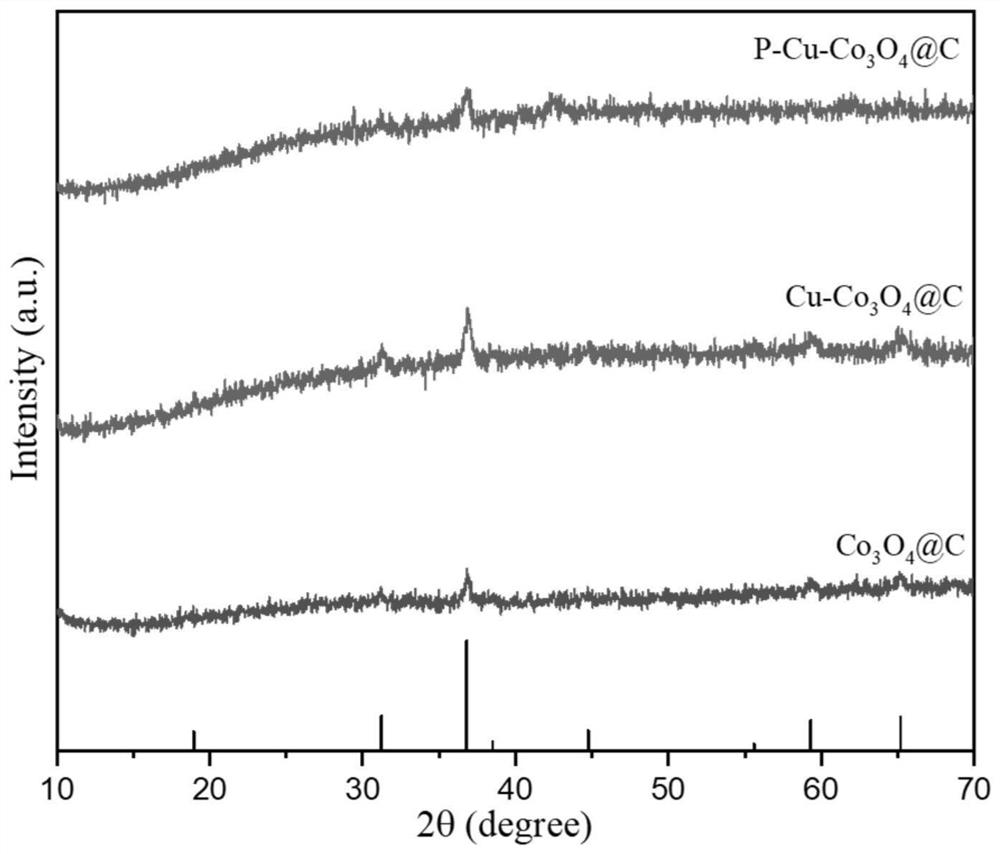

[0045] Cu-Co prepared in this embodiment 3 o 4 @C Catalyst XRD as figure 1 Shown, Cu-Co 3 o 4 The main phase of @C material is Co 3 o 4 phase, indicating that Cu was successfully doped into Co 3 o 4 middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com