Moisture-proof mite allergen soluble microneedle

An allergen, soluble technology, applied in the direction of allergen antigen components, microneedles, needles, etc., can solve the problems of poor mechanical properties, uncertainty in the selection of matrix materials, and no consideration of humidity factors, and achieve good mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Preparation of Mite Allergen Soluble Microneedle Female Mold

[0039] like figure 1 , the present invention adopts MEMS technology in combination with inverted mold method to prepare microneedle negative mold, and the steps are as follows:

[0040] 1) Preparation of monocrystalline silicon positive mold microneedles

[0041] The male mold microneedle is prepared by MEMS technology, the microneedle is listed as 10*10, the height of the needle is 600 μm, the diameter of the bottom is 300 μm, and the diameter of the needle tip is ≤10 μm.

[0042] 2) Preparation of polydimethylsiloxane mold

[0043] After mixing polydimethylsiloxane and curing agent at a mass ratio of 8:1, pour it into a cuboid container with a single crystal silicon positive mold microneedle; place the container in a vacuum drying oven at a vacuum degree of 0.1MPa Vacuumize for 3 minutes to remove the air bubbles in the mixture; put it into an oven, dry it at 80° C. for 3 hours, and take it ou...

Embodiment 2

[0044] Example 2 Preparation of Mite Allergen Soluble Microneedles

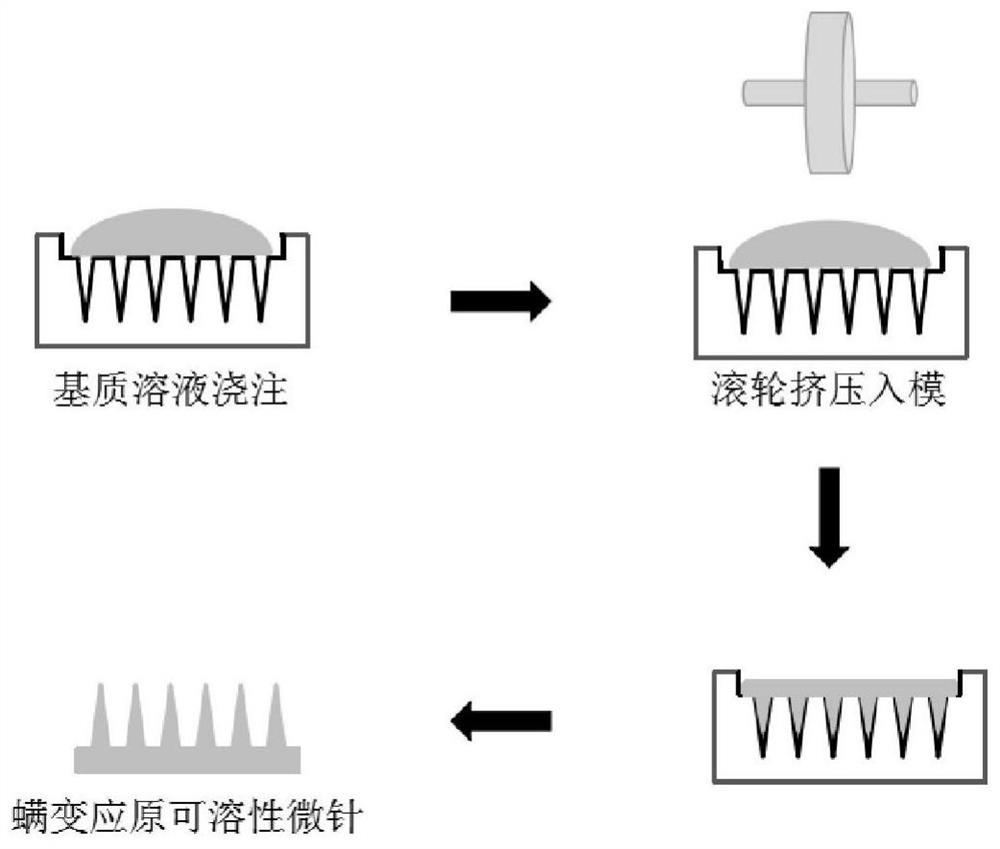

[0045] like figure 2 , the present invention adopts extrusion molding method to prepare mite allergen soluble microneedles, the steps are as follows:

[0046] 1) After mixing the matrix material and the mite allergen according to the prescription ratio, dissolve it with phosphate buffered saline (PBS) with a pH of 7.4 to form a uniform mixed solution (i.e. matrix solution), take an appropriate amount of matrix solution into a centrifuge tube, Put it in a centrifugal precipitator, centrifuge to remove the air bubbles in the matrix solution, and let it stand for later use.

[0047] 2) Take the matrix solution obtained after centrifugation in step 1), pour it on the polydimethylsiloxane mold prepared in Embodiment 1 of the present invention, then place the polydimethylsiloxane mold on a plane, and squeeze it with a roller The matrix solution above the mold goes back and forth several times, so that the matrix...

Embodiment 3

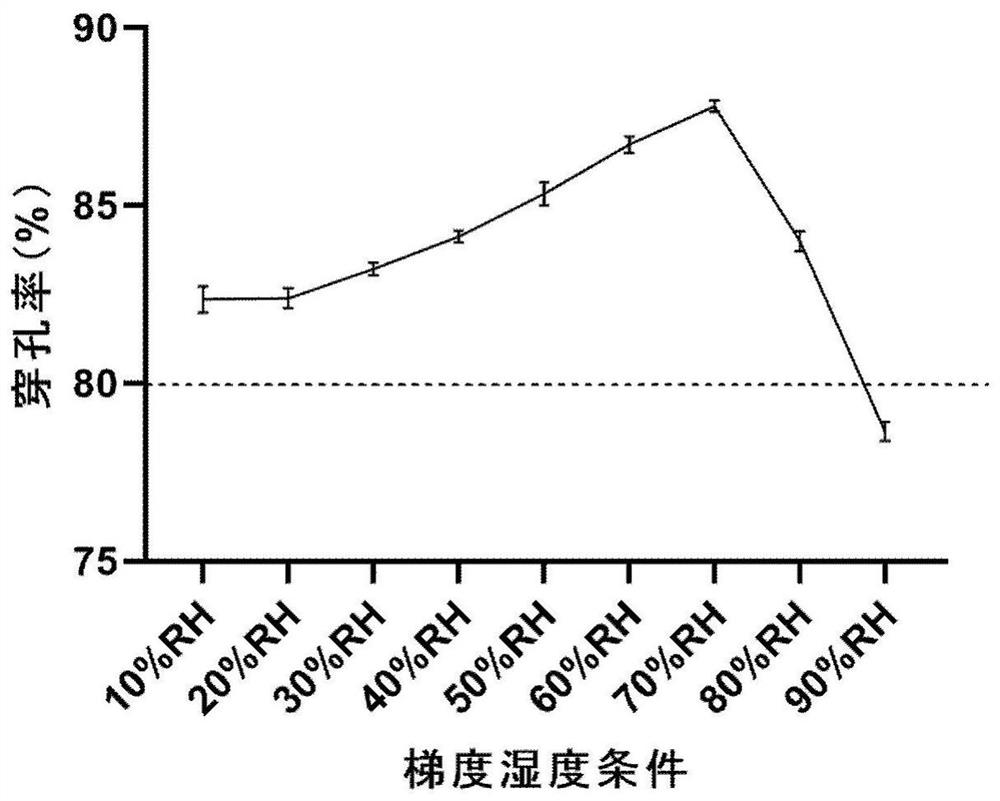

[0048] Example 3 Effects of Different Humidity Conditions on the Mechanical Properties and Activity of Mite Allergen Soluble Microneedles

[0049] In the present invention, the matrix material is intended to be a high-molecular polymer. Based on the research of the aforementioned literature, this embodiment intends to use methyl vinyl ether-maleic anhydride copolymer (Gantrez S-97) to load the mite allergen preparation Adult mite allergen-soluble microneedles, by measuring the mechanical strength and mite allergen activity changes of mite allergen-soluble microneedles under different humidity conditions, to explore the effect of humidity conditions on the mite allergen-soluble microneedles mechanical properties and effect on activity. Humidity conditions are selected from 10% to 90% relative humidity (10 to 90% RH). To provide a premise basis for the follow-up microneedle material composition, combination with allergens, and their relationship with each other on the impact of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com