Device and method for measuring thermal resistance of nucleating layer of gallium nitride device based on picosecond laser

A picosecond laser and measuring device technology, which is applied to measuring devices, single semiconductor device testing, measuring electricity, etc., can solve the problem of inability to measure the thermal resistance of the device nucleation layer and the measurement of the thermal characteristics of the nucleation layer of gallium nitride HEMT. , slow transient switching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The technical solutions of the present invention will be further specifically described below through embodiments and in conjunction with the accompanying drawings. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0065] The main English abbreviations involved in the present invention: 1. RC resistance and capacitance, 2. HEMT high electron mobility transistor, 3. TSP temperature sensitive parameter, 4. CMOS complementary metal oxide semiconductor, 5. G device gate, 7. D device Drain, 8, S device source.

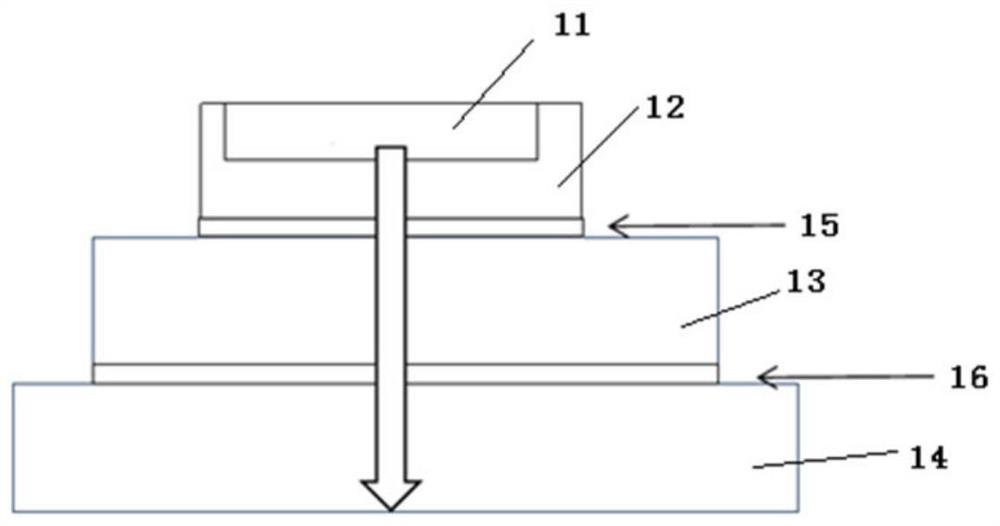

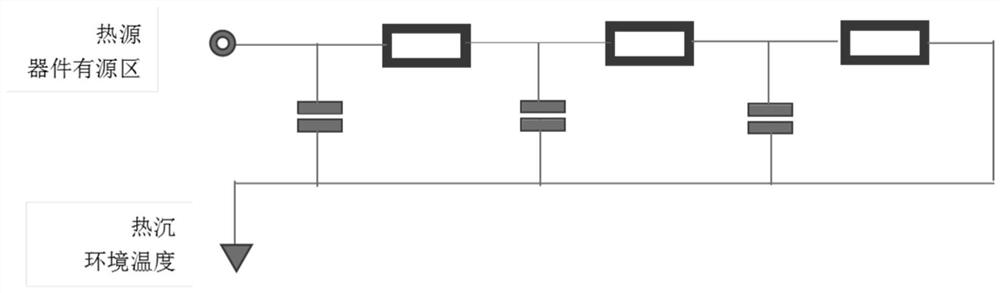

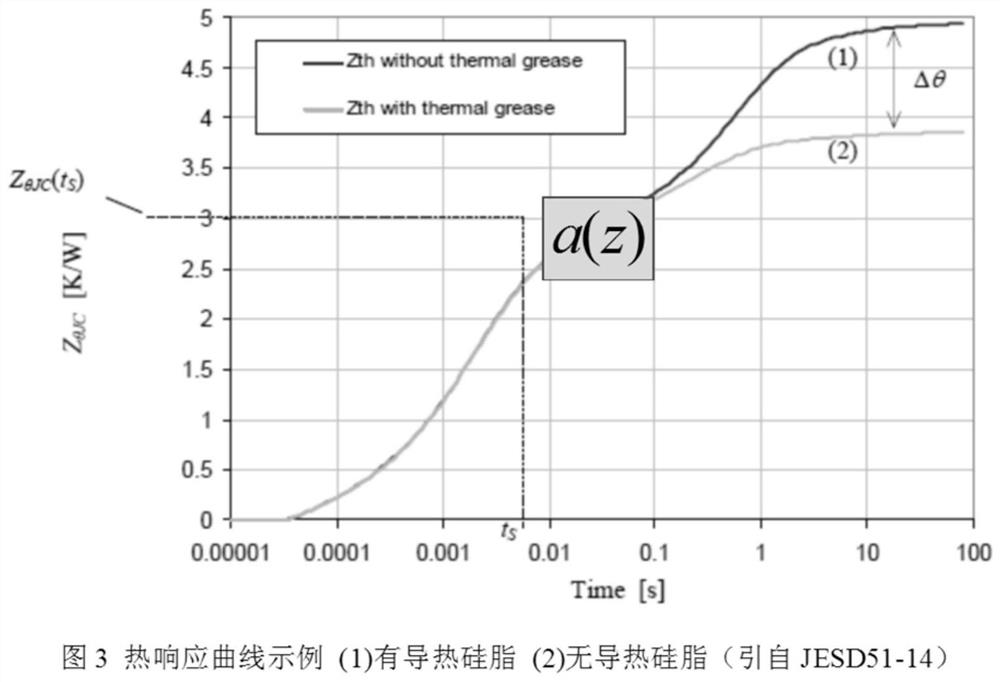

[0066] A device for measuring the thermal resistance of the nucleation layer of GaN devices based on picosecond lasers of the present invention adopts a method for measuring the thermal resistance of GaN device thin layers based on picosecond laser heating, which is different from the prior art The main reason is to use the picosecond laser heating method to heat the thin layer of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com