Carbon/magnetic electromagnetic wave absorbing material with sandwich structure and preparation method thereof

A technology for absorbing materials and electromagnetic waves, applied in the fields of magnetic/electric field shielding, electrical components, etc., can solve the problems of heavy weight, difficult molding, single electromagnetic wave loss mechanism, etc., achieve light weight, magnetic loss performance, and improve electromagnetic wave absorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

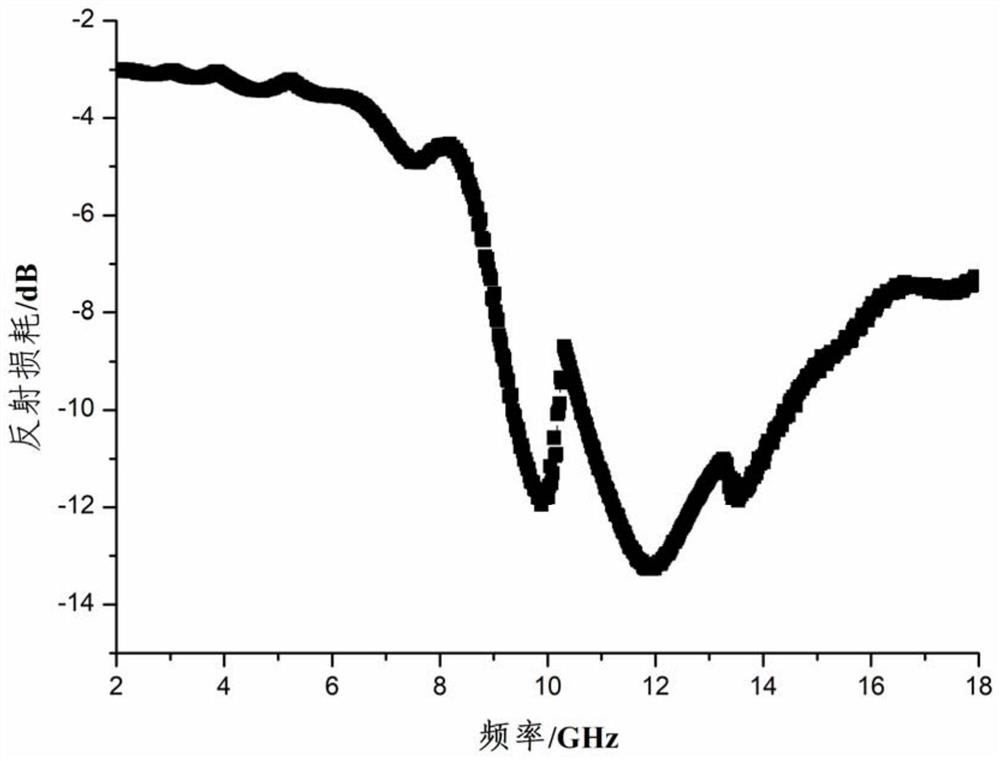

Embodiment 1

[0019] (1) Dissolve 2g of anhydrous ferric chloride into 20ml of diethylene glycol to prepare a metal salt solution;

[0020] (2) Add 2g of citric acid-sodium citrate buffer (pH=10) to the solution in step 1, stir to dissolve and let stand for 5 minutes to prepare the solution;

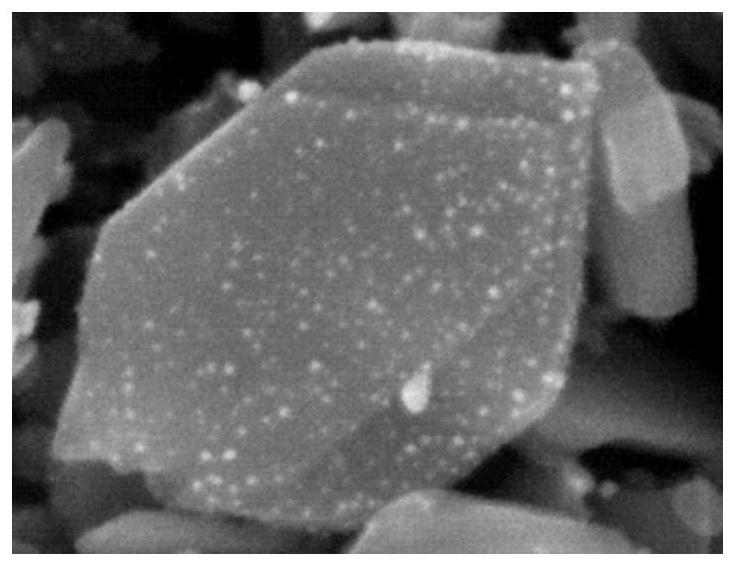

[0021] (3) Transfer the solution prepared in step 2 to a Teflon-lined stainless steel autoclave and keep it at 200°C for 8 hours. Vibrate once in 30 minutes to prevent the agglomeration of particles; then take it out and wash it with deionized water and dry it to obtain flake ferric oxide;

[0022] (4) Prepare 1g / L dopamine hydrochloride, and use citric acid-sodium citrate buffer to adjust the pH of the solution to 8.5;

[0023] (5) Put 5g of flaky iron ferric oxide into 50ml of the solution prepared in step 4, and then shake and react in a water bath at 30°C for 10 hours to obtain a flaky material coated with polydopamine. The thickness of polydopamine is 5nm;

[0024] (6) Place the material prepar...

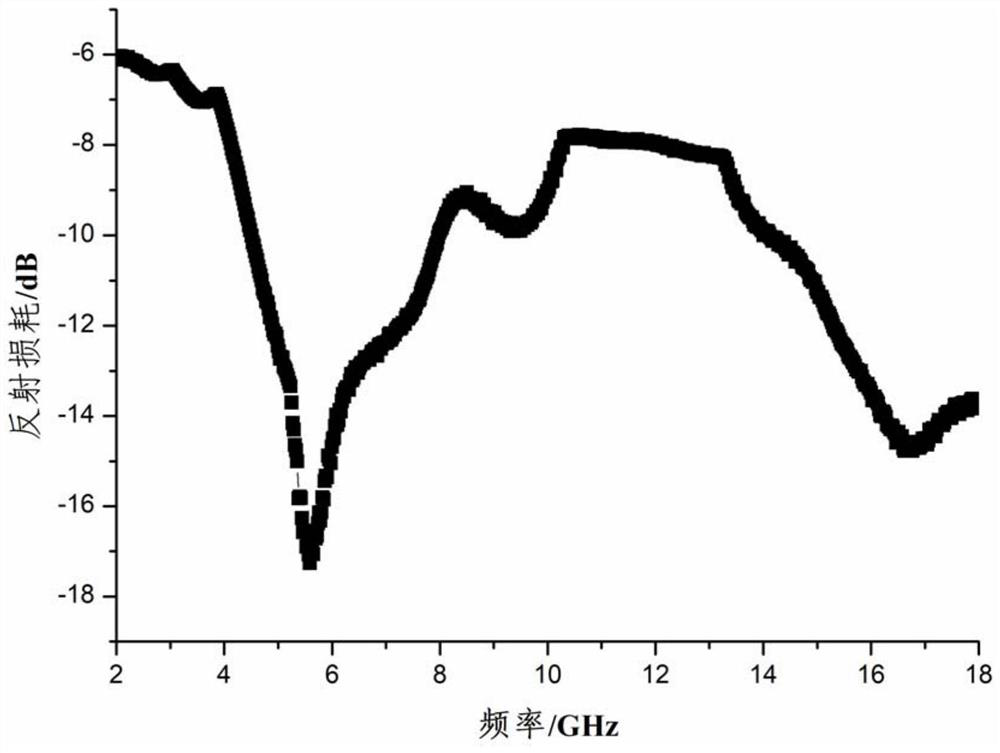

Embodiment 2

[0028] (1) Dissolve 10g of anhydrous ferric chloride into 80ml of diethylene glycol to prepare a metal salt solution;

[0029] (2) Add 5g of citric acid-sodium citrate buffer (pH=10) into the solution in step 1, stir to dissolve and let stand for 5 minutes to prepare the solution;

[0030] (3) Transfer the solution prepared in step 2 to a Teflon-lined stainless steel autoclave and keep it at 200°C for 8 hours. Vibrate once in 30 minutes to prevent the agglomeration of particles; then take it out and wash it with deionized water and dry it to obtain flake ferric oxide;

[0031] (4) Prepare 2g / L dopamine hydrochloride, and adjust the pH of the solution to 8.5 with citric acid-sodium citrate buffer;

[0032] (5) Put 10g of flaky iron ferric oxide into 80ml of the solution prepared in step 4, and then shake and react in a water bath at 30°C for 24 hours to obtain a sheet-like material coated with polydopamine. The thickness of polydopamine is 10nm;

[0033] (6) Place the materia...

Embodiment 3

[0037] (1) Dissolve 10g of anhydrous ferric chloride into 80ml of diethylene glycol to prepare a metal salt solution;

[0038] (2) Add 5 g of citric acid-sodium citrate buffer (pH=10) to the solution in step 1, stir to dissolve and let stand for 5 minutes to prepare the solution;

[0039] (3) Transfer the solution prepared in step 2 to a Teflon-lined stainless steel autoclave and keep it at 200°C for 8 hours. Vibrate once in 30 minutes to prevent the agglomeration of particles; then take it out and wash it with deionized water and dry it to obtain flake ferric oxide;

[0040] (4) Prepare 2g / L dopamine hydrochloride, and adjust the pH of the solution to 8.5 with citric acid-sodium citrate buffer;

[0041] (5) Put 10g of flaky iron ferric oxide into 80ml of the solution prepared in step 4, and then shake and react in a water bath at 30°C for 24 hours to obtain a sheet-like material coated with polydopamine. The thickness of polydopamine is 10nm;

[0042] (6) Place the material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com