Polyolefin composite film as well as preparation method and application thereof

A polyolefin and composite membrane technology, applied in the field of medical membrane materials, can solve the problems of changes in the physical and chemical properties of the membrane surface of the membrane material and bring medical risks, and achieve excellent anti-plasma leakage performance, excellent blood compatibility, Effect of excellent gas exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of polyolefin composite film provided by the invention comprises the following steps:

[0035] S1, providing an organic phase solution and an aqueous phase solution, wherein the organic phase solution includes a second polyolefin, a crosslinking agent, and a water-insoluble initiator, and the aqueous phase solution includes an anticoagulant molecule and a water-soluble initiator, anti-coagulant The molecular chain of the condensate molecule contains unsaturated bonds;

[0036] S2, providing a support membrane, placing the organic phase solution on the surface of the support membrane, and performing the first heat treatment to obtain a nascent membrane, wherein the material of the support membrane is the first polyolefin and has pores, and the second polyolefin is in the support membrane. A dense layer is formed on the surface, and the temperature of the first heat treatment is less than the critical temperature of the water-insoluble initiator; an...

Embodiment 1

[0083] 2 grams of PMP, 0.035 grams of dimethyl azobisisocarboxylate, 0.965 grams of methylenebisacrylamide and 97 grams of cyclohexane were blended, and stirred at room temperature for 6 hours to fully dissolve, and after defoaming, a uniform organic phase solution.

[0084] 15 grams of sodium styrene sulfonate, 15 grams of acrylic acid and 0.025 grams of azobisisobutylamidine hydrochloride were sequentially added to 70 grams of deionized water, and stirred to fully dissolve to obtain an aqueous phase solution.

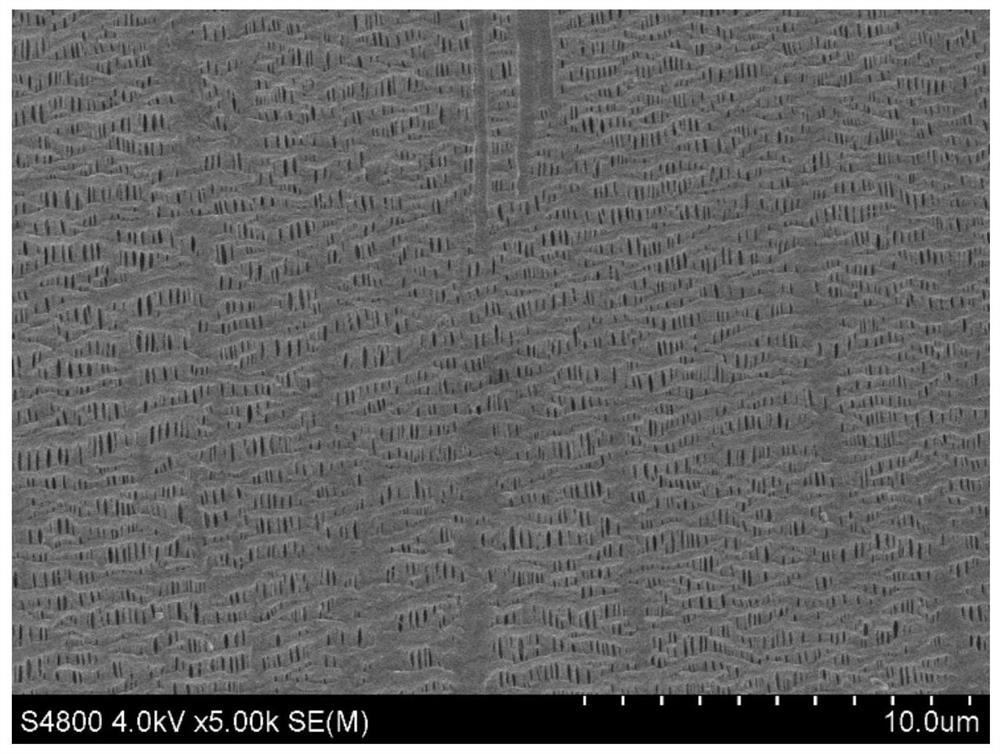

[0085] Provide a support film, the material of the support film is polypropylene, the thickness is 30 microns, the scanning electron microscope picture of the support film is as follows figure 1 shown by figure 1 It can be seen that the average pore diameter of the support membrane is 100 nanometers, and the surface of the support membrane is cleaned with a volume fraction of 30% ethanol aqueous solution.

[0086] The organic phase solution was scraped onto the surf...

Embodiment 2

[0097] Blend 1.5 grams of PMP, 0.023 grams of azobisisobutyronitrile, 0.477 grams of ethylene glycol diacrylate and 98 grams of chloroform, and stir at room temperature for 2 hours to fully dissolve, and obtain a uniform organic phase after defoaming solution.

[0098] Add 10 grams of sodium styrene sulfonate, 5 grams of methacryloyl ethyl sulfobetaine and 0.01 grams of sodium persulfate into 85 grams of deionized water in sequence, stir to fully dissolve and obtain an aqueous phase solution.

[0099] A support membrane is provided, the material of the support membrane is polyethylene, the thickness is 10 microns, the average pore diameter of the support membrane is 300 nanometers, and the surface of the support membrane is cleaned with a volume fraction of 15% ethanol aqueous solution.

[0100] The organic phase solution was scraped onto the cleaned surface of the support membrane, and heat treated at 40° C. for 4 minutes to obtain a nascent membrane.

[0101] The nascent fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com