Preparation method of phenolic aldehyde-based super-hydrophilic carbon nanofiber net film

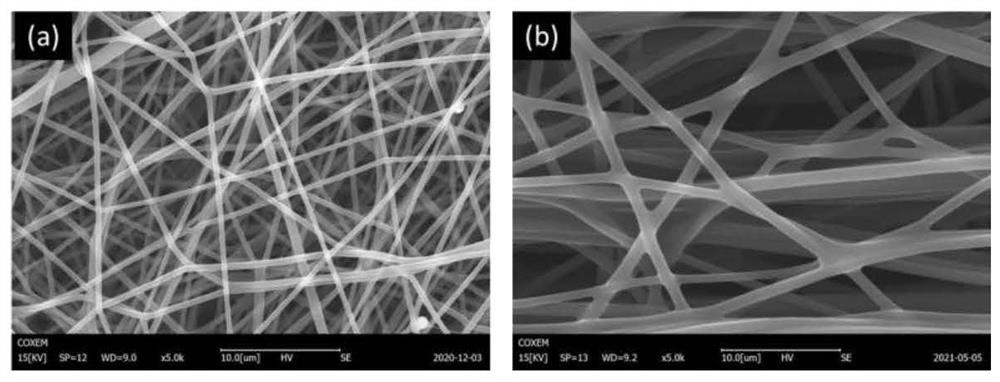

A carbon nanofiber and nanofiber technology, which is applied in the field of separation membrane material preparation, can solve the problem that the output and size of carbon nanofiber membranes are easily limited by vapor phase growth efficiency, and it is difficult to effectively guarantee the structural stability of suction filtration devices and membrane materials. Due to the low degree of entanglement between the fibers of the nanofiber membrane, the effects of stable structure and physicochemical properties, diverse sample sizes and a wide range of sources are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of phenolic base ultra-hydrophilic carbon nanofiber mesh film and preparation method thereof, concrete steps are as follows:

[0047] Step (1): Take the mixture of thermoplastic phenolic resin and thermosetting phenolic resin as raw material according to the mass ratio of 1:9, use polyacrylonitrile as accompanying spinning polymer, use stannous chloride as additive, and use N,N-di Methyl formamide is used as a solvent, the mass fraction of the phenolic resin mixture is 7wt%, the mass fraction of polyacrylonitrile is 10wt%, and the mass fraction of stannous chloride is 1wt%, and the spinning solution is prepared by fully stirring at room temperature.

[0048] Step (2): The spinning liquid is added to a multi-nozzle electrospinning machine equipped with a uniform-speed reciprocating spraying device and a fiber receiving substrate for electrospinning. The fiber receiving substrate is aluminum foil, the spinning voltage is 25kV, and the receiving distance is 20cm, th...

Embodiment 2

[0054] A kind of phenolic base ultra-hydrophilic carbon nanofiber mesh film and preparation method thereof, concrete steps are as follows:

[0055] Step (1): Take a mixture of thermoplastic phenolic resin and thermosetting phenolic resin as a raw material according to a mass ratio of 1:9, use polyvinyl butyral as a companion spinning polymer, use stannous chloride as an additive, and use N , N-dimethylformamide is the solvent, the mass fraction of the phenolic resin mixture is 5wt%, the mass fraction of polyvinyl butyral is 5wt%, and the mass fraction of stannous chloride is 7wt%, fully stirred at room temperature to prepare spinning solution.

[0056] Step (2): The spinning liquid is added to a multi-nozzle electrospinning machine equipped with a uniform-speed reciprocating spraying device and a fiber receiving substrate for electrospinning. The fiber receiving substrate is aluminum foil, the spinning voltage is 25kV, and the receiving distance is 20cm, the ambient temperatu...

Embodiment 3

[0061] A kind of phenolic base ultra-hydrophilic carbon nanofiber mesh film and preparation method thereof, concrete steps are as follows:

[0062] Step (1): Take water-soluble phenolic resin (thermoplastic and thermosetting mixture) as the raw material according to the mass ratio of 2:8, use polyvinyl alcohol as the companion spinning polymer, use silica nanoparticles as the additive, and use water as the Solvent, the mass fraction of the phenolic resin mixture is 10wt%, the mass fraction of polyvinyl alcohol is 8wt%, the mass fraction of silica nanoparticles is 6wt%, the water bath is heated at 60 ° C and stirred thoroughly, and then ultrasonic dispersion treatment is used for 15 minutes to obtain the spinning solution.

[0063] Step (2): The spinning solution is added to a multi-nozzle electrospinning machine equipped with a uniform speed reciprocating spraying device and a fiber receiving substrate for electrospinning. The fiber receiving substrate is a metal mesh, the spin...

PUM

| Property | Measurement | Unit |

|---|---|---|

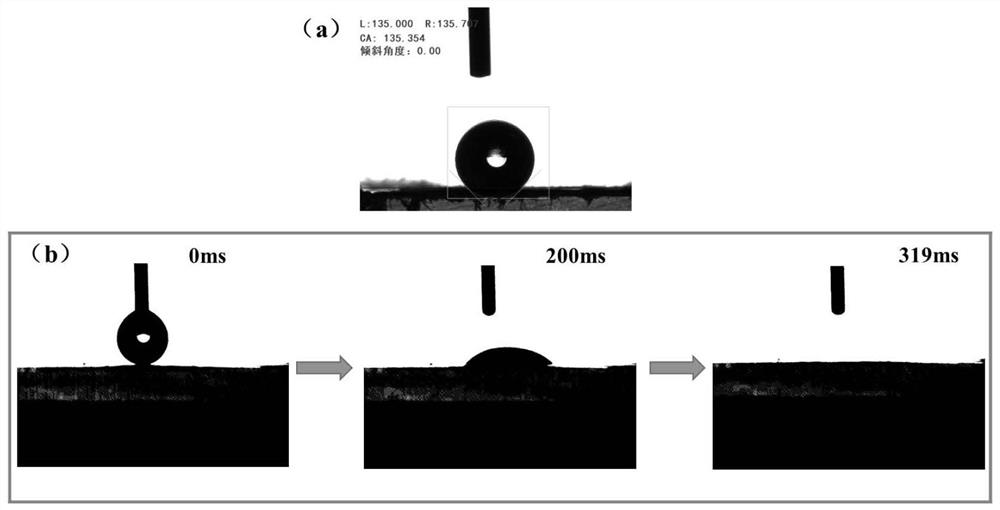

| contact angle | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com