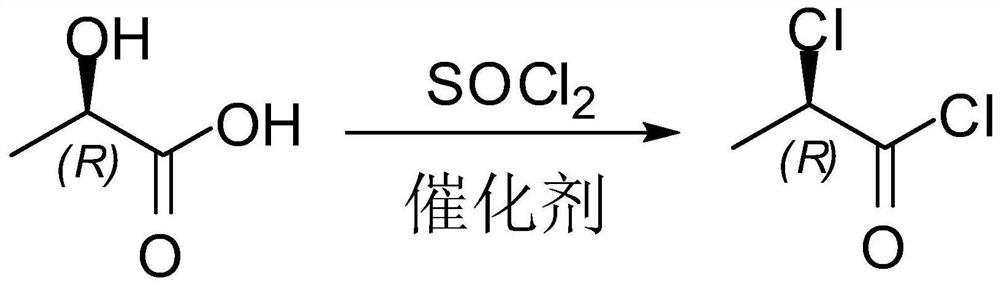

Method for preparing D-(+)-2-chloropropionyl chloride by adopting microchannel continuous flow reactor

A chloropropionyl chloride, microreactor technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, carboxylate preparation, etc., can solve the problem of large water content of L-lactic acid, low optical purity of products, synthesis Problems such as long steps, to achieve the effects of less by-products, high product purity, and less three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

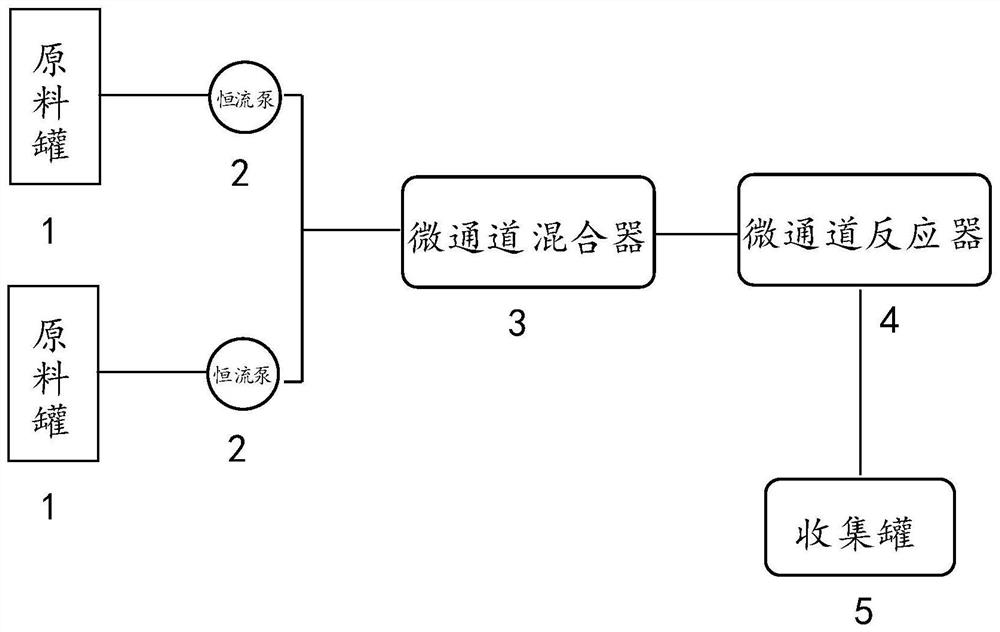

[0039] according to figure 1 Build a microchannel continuous flow reactor for reaction:

[0040] (1) Weigh 120g of L-lactic acid and add dichloromethane to a volume of 1L, add 12g of 2,6-di-tert-butylpyridine, and stir to obtain solution A;

[0041] (2) Weigh 300 g of thionyl chloride and add dichloromethane to a volume of 1 L, and stir to obtain solution B;

[0042] (3) The homogeneous solution A and the homogeneous solution B were respectively pumped into the micro-mixer at a flow rate of 0.5 mL / min, the mixing temperature was 5° C., and the reaction residence time was 40 minutes. After mixing, pass into the microreactor, the reaction temperature is controlled at 50°C, and the reaction residence time is 3 hours. Collect the effluent of the microreactor and obtain the D-(+)-2-chloropropionyl chloride fraction 161.9g after vacuum distillation to recover the solvent after normal pressure distillation; the yield is 96.4%; the product purity is 99.7%, and the optical purity rea...

Embodiment 2

[0044] according to figure 1 Build a microchannel continuous flow reactor for reaction:

[0045](1) Weigh 120g of L-lactic acid and add dichloromethane to a volume of 500mL, add 12g of 2,6-di-tert-butylpyridine, and stir to obtain solution A;

[0046] (2) Weigh 300g of thionyl chloride and add dichloromethane to a volume of 500mL, and stir to obtain solution B;

[0047] (3) The homogeneous solution A and the homogeneous solution B were respectively pumped into the micro-mixer at a flow rate of 0.5 mL / min, the mixing temperature was 5° C., and the reaction residence time was 40 minutes. After mixing, pass into the microreactor, the reaction temperature is controlled at 50°C, and the reaction residence time is 3 hours. Collect the effluent of the microreactor and obtain the D-(+)-2-chloropropionyl chloride fraction 159.5g after vacuum distillation to recover the solvent after normal pressure distillation; the yield is 95%; the product purity is 99.1%, and the optical purity re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com