High-turbulivity small wet anaerobic digestion reactor and operation control method

An anaerobic digestion and reactor technology, which is applied in biochemical equipment and methods, gas production bioreactors, bioreactor/fermenter combinations, etc. Problems such as low degradation rate of organic matter, to achieve the effect of accelerating fluid flow rate, high degradation rate of organic matter, and good degree of homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

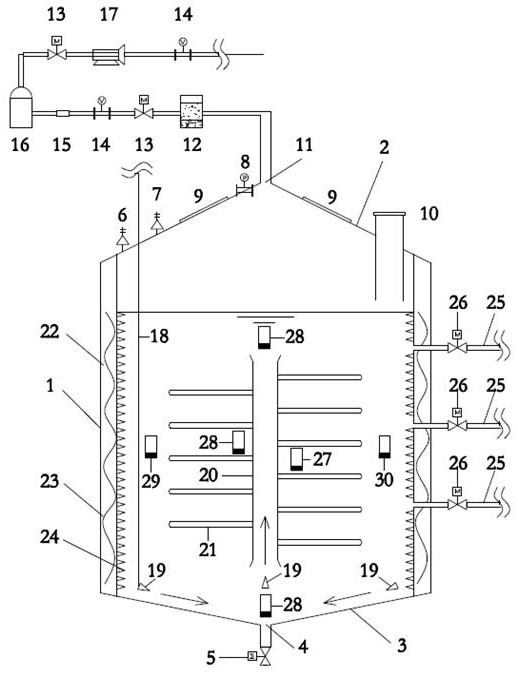

[0046] Such as figure 1 shown ( figure 1 The specific wiring of each monitor sensor wire and stirring air pipe is omitted), the main body of the reactor is an integrated structure formed by connecting a cylinder 1 with an equal-diameter conical top 2 and a conical bottom 3, placed vertically, and conical The ratio of height to diameter of top 2, cylinder 1, and conical bottom 3 is 5:20:2:20. The liquid level shall be at least 0.3m from the horizontal plane where the cylinder meets the conical top. A slag outlet 4 is opened at the tip of the conical bottom, which is opened and closed by a slag discharge solenoid valve 5 .

[0047] The conical top is equipped with an overpressure safety valve 6, a vacuum safety valve 7, and a gas pressure gauge 8. The top of the cone is provided with two viewing ports 9, which are located at symmetrical positions on the same diameter. Conical top opens a round hole, as feed inlet 10, connects vertical feed standpipe with screw thread, and st...

Embodiment 2

[0052] run method

[0053] (1) Medium-temperature digestion, the temperature is controlled at about 35°C, cycle operation, intermittent feeding and liquid discharge, 25-30 days per cycle.

[0054] (2) The control method of the physical and chemical characteristics of the feed: control the physical and chemical properties and components of the feed, in which the moisture content is controlled at 93%~98%, the inorganic particles are removed, the fiber length is not greater than 4 cm, and the oil content of the feed should not be greater than 15%. The carbon-to-nitrogen ratio is between 10 and 50. When the dry plant straw content exceeds 50% of the total amount of the feed mixture (by mass), the mixture must be pre-stacked with water.

[0055] (3) Start-up method of anaerobic flora cultivation: add 20% of raw material mixture and 80% of domestic sewage (by volume) for the first feed, and no inoculum may be added. At the end of the first cycle, about 1 / 3 of the effective volume o...

Embodiment 3

[0060] An anaerobic digestion project in an agricultural park in Tianjin built a reactor according to this patented method, with a total height of 1.6 meters and a diameter of 2 meters. The raw material for digestion is a mixture of activated sludge, plant straw, and pig farm manure, accounting for about 68%, 12% and 20% (by mass) respectively. The comprehensive moisture content of the mixture is 96%, and the carbon-nitrogen ratio is about 27% ︰1. Plant stalks are rolled and cut to less than 4 cm.

[0061] See Table 1 for the control methods in the start-up phase. By the end of the fourth cycle, the methane content of the biogas will reach 65%, and the gas production will be 700L / kg dry weight. Table 1

[0062]

[0063] After successful startup, it enters the stable operation stage. During stable operation, each digestion takes 30 days. The median temperature is set to 35°C, and when the temperature difference exceeds 2°C, the heating device will be triggered to start ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com